When it comes to industrial applications that demand high performance and reliability, PTFE smooth-bore tubing stands out as a top choice. This versatile material offers a range of benefits that make it ideal for various industries, from chemical processing to food and beverage production. In this article, we’ll explore the many advantages of PTFE smooth-bore tubing and why it’s a preferred option for fluid transfer and other applications.

What is PTFE Smooth Bore Tubing?

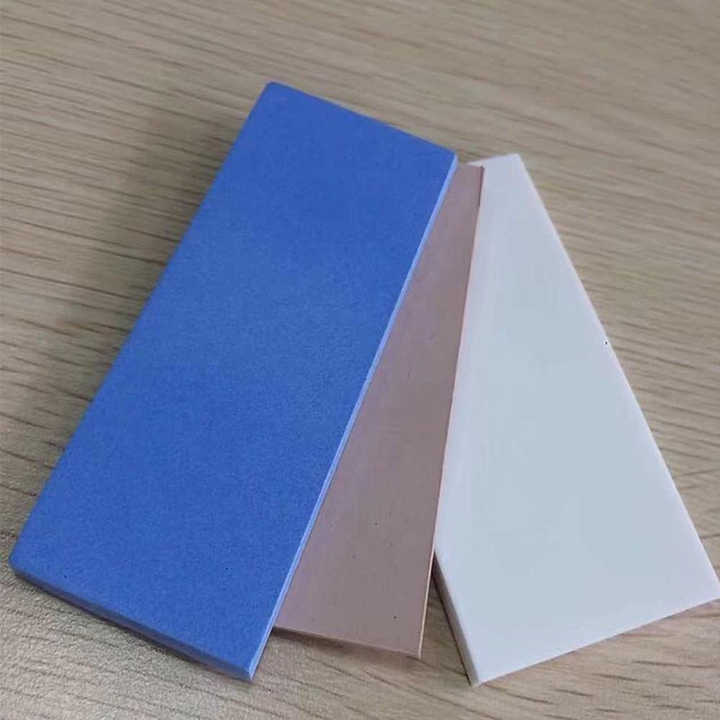

PTFE, or Polytetrafluoroethylene, is a synthetic fluoropolymer known for its exceptional chemical resistance and non-stick properties. PTFE smooth-bore tubing, often referred to as a smooth-bore Teflon tube, is a type of hose made from this material. Its smooth inner surface allows for efficient fluid transfer, making it a popular choice in various industries.

Key Characteristics

- Chemical Resistance: PTFE smooth-bore tubing is highly resistant to a wide range of chemicals, making it an excellent choice for applications involving corrosive substances. This chemical resistance ensures that the tubing remains intact and functional even in harsh environments.

- Temperature Tolerance: One of the standout features of PTFE tubing is its ability to withstand extreme temperatures. It can operate efficiently in temperatures ranging from -328°F to 500°F (-200°C to 260°C), making it suitable for both cryogenic and high-temperature applications.

- Non-Stick Surface: The non-stick properties of PTFE prevent substances from adhering to the tubing’s inner walls. This feature is particularly useful in industries where cleanliness and ease of cleaning are essential.

- Flexibility: Despite its robust nature, PTFE smooth-bore tubing is highly flexible, allowing it to be used in applications where maneuverability is crucial. Its flexibility also makes installation easier in tight or complex spaces.

Advantages of PTFE Smooth Bore Tubing

1. Chemical-Resistant Hose

PTFE smooth-bore tubing is widely recognized for its chemical resistance. It can handle a wide variety of aggressive chemicals without degrading, making it an ideal choice for industries that deal with corrosive substances. Whether it’s acids, solvents, or bases, PTFE tubing can transport them safely and efficiently.

2. High Purity PTFE Tube

In industries like pharmaceuticals and food processing, maintaining the purity of materials being transported is crucial. PTFE smooth-bore tubing’s non-reactive nature ensures that it does not contaminate the substances it carries. This high purity makes it a preferred choice for applications requiring stringent cleanliness standards.

3. PTFE Fluid Transfer

The smooth inner surface of PTFE tubing minimizes friction and resistance during fluid transfer. This efficient flow characteristic is essential in industries where precise and consistent fluid movement is necessary. The smooth-bore design also reduces the risk of clogging and buildup, ensuring uninterrupted operations.

4. Versatility in Applications

PTFE smooth-bore tubing’s versatility is one of its most appealing features. It finds applications in a wide range of industries, including:

- Chemical Processing: For handling aggressive chemicals and maintaining safety.

- Food and Beverage: Ensuring contamination-free transfer of liquids and gases.

- Pharmaceutical: Maintaining high purity standards in drug manufacturing.

- Automotive: Used in fuel and brake systems for its heat and chemical resistance.

5. Durability and Longevity

PTFE tubing is known for its durability and long lifespan. Its resistance to wear and tear, combined with its ability to withstand harsh environments, ensures that it remains functional over extended periods. This durability translates to cost savings, as the need for frequent replacements is minimized.

6. PTFE Corrosion-Resistant Tube

Corrosion can be a significant concern in many industrial applications. PTFE smooth-bore tubing’s corrosion-resistant properties make it an excellent choice for environments where exposure to corrosive substances is common. Its ability to resist corrosion extends its service life and ensures reliable performance.

7. Environmental and Safety Benefits

PTFE is an environmentally friendly material, as it does not release harmful substances into the environment. Additionally, its chemical resistance and non-stick properties reduce the need for harsh cleaning agents, contributing to safer and more sustainable operations.

Choosing the Right PTFE Tubing for Your Needs

When selecting PTFE smooth bore tubing for your specific application, it’s essential to consider factors such as the type of chemicals involved, temperature requirements, and the desired flexibility. Consulting with a supplier or manufacturer can help you determine the most suitable tubing for your needs.

Customization Options

Many manufacturers offer customization options for PTFE tubing, allowing you to tailor the product to meet your specific requirements. This customization can include variations in diameter, wall thickness, and length, ensuring that the tubing fits perfectly within your system.

Conclusion

PTFE smooth-bore tubing offers a myriad of advantages that make it a preferred choice for numerous industrial applications. From its exceptional chemical resistance and temperature tolerance to its non-stick and flexible nature, PTFE tubing provides reliable and efficient solutions for fluid transfer and more. Whether you’re in the chemical, pharmaceutical, or food and beverage industry, PTFE smooth-bore tubing is an investment in quality and performance that you can count on.

By understanding the benefits and capabilities of PTFE tubing, you can make informed decisions that enhance the efficiency and safety of your operations. Consider integrating PTFE smooth-bore tubing into your systems and experience the advantages for yourself.