3D printing has revolutionized the way prototypes and custom parts are manufactured, offering versatility and precision that was previously unimaginable. Among the various components that contribute to the smooth operation of a 3D printer, the PTFE tube stands out as an essential yet often overlooked part. Let’s delve into the advantages of using PTFE tubes in 3D printing and how they can improve your printing experience.

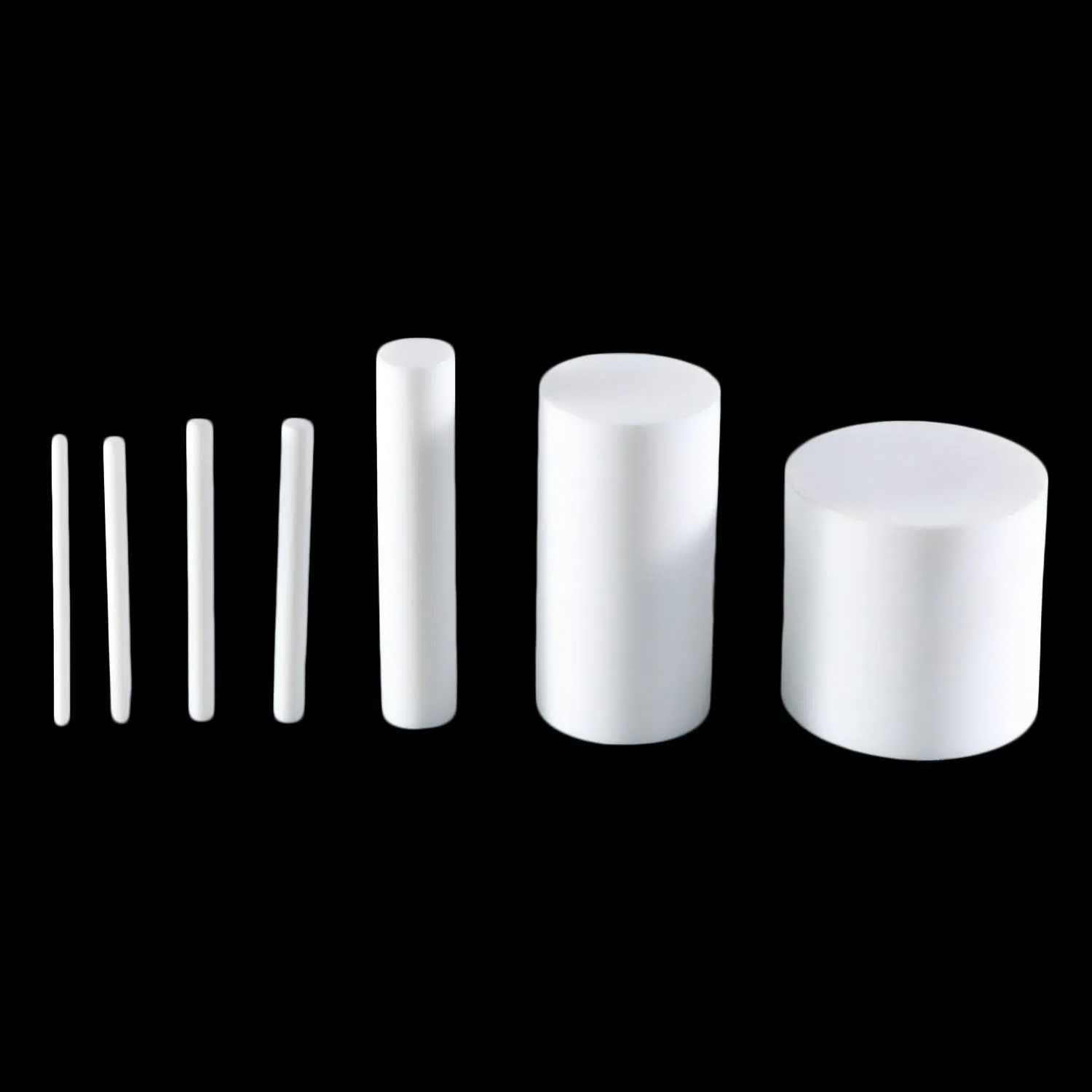

Polytetrafluoroethylene, or PTFE, is a synthetic fluoropolymer of tetrafluoroethylene known for its unique material properties. It’s widely used in various applications due to its high resistance to heat, low friction, and non-reactivity with most chemicals. These characteristics make PTFE tubing an ideal choice for 3D printer parts, especially for guiding filament.

Smooth Filament Feed

One of the primary benefits of using PTFE tubes in 3D printing is their ability to provide a smooth filament feed. When the filament is guided through a PTFE tube, the low-friction surface minimizes resistance, ensuring a consistent and precise flow of material. This leads to improved print quality and reduces the risk of clogs and jams in the filament extrusion process.

Enhanced Temperature Resistance

PTFE tubes are capable of withstanding high temperatures, which is crucial in 3D printing as the filament is heated to a specific degree for proper extrusion. PTFE tubing ensures that even at elevated temperatures, the tube remains stable and does not degrade, maintaining its shape and functionality. This durability adds to the reliability of the 3D printer over time.

Versatility in 3D Printer Upgrades

When considering 3D printer upgrades, incorporating PTFE tubes is a simple yet effective enhancement. These tubes can be used as filament guides, making them an integral part of the filament feed system. Their adaptability allows them to be easily fitted into various 3D printer models, making them a versatile choice for both beginners and experienced users alike.

Improved Filament Extrusion

The precision of filament extrusion is vital for producing high-quality prints. PTFE tubes aid in this process by ensuring that the filament is fed smoothly and consistently. This consistency reduces the chances of under-extrusion or over-extrusion, which can lead to defects in the printed object.

Cost-Effective Maintenance

PTFE tubes are not only effective but also affordable, making them an attractive option for maintaining and upgrading 3D printers. Replacing a PTFE tube is a cost-effective way to ensure the longevity and efficiency of your 3D printer without incurring significant expenses.

In conclusion, PTFE tubes offer a myriad of advantages that enhance the functionality and reliability of 3D printers. From smooth filament feeding to excellent temperature resistance, these tubes are a valuable addition to any 3D printing setup. Whether you’re looking to upgrade your 3D printer or maintain its optimal performance, PTFE tubes are a wise choice to consider.