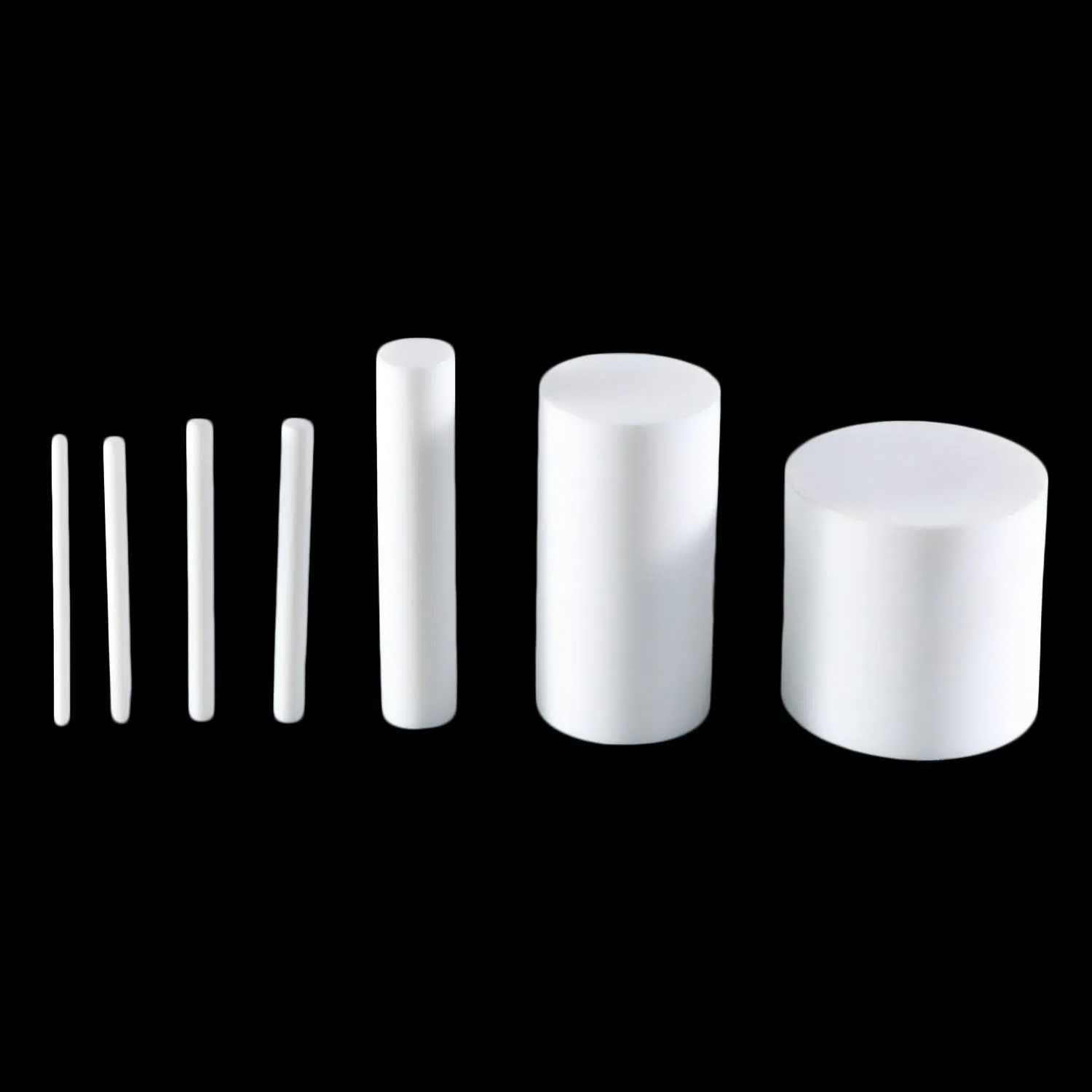

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer known for its remarkable resistance to heat, chemicals, and electrical conductivity. This high-performance material has set the standard for durability and versatility in challenging conditions. Teflon, a brand name coined by Chemours, is one of the most recognized forms of PTFE. It has become synonymous with non-stick applications in the consumer market, yet its industrial applications are even more noteworthy.

PTFE’s unique molecular structure gives it its non-stick, heat-resistant, and chemical-resistant properties, making it an ideal material for a variety of applications, including tubing. The structure consists of a carbon backbone surrounded by fluorine atoms, which creates a robust shield against various environmental factors. This makes it particularly effective in industries where chemical exposure and thermal resilience are paramount.

Key Advantages of PTFE Teflon Tubes

High-Temperature Resistance

One of the standout features of PTFE Teflon tubes is their ability to withstand high temperatures. These tubes maintain their integrity even when exposed to temperatures as high as 260°C (500°F). This property is crucial for processes involving extreme heat, where other materials might fail or degrade. This makes them suitable for industries where high-temperature processes are common, such as in the chemical, automotive, and aerospace sectors.

Moreover, PTFE Teflon tubes do not just survive high temperatures; they maintain their performance without losing any of their mechanical properties. This ensures consistent operation and reduces the risk of system failures. Their thermal stability also allows for efficient heat transfer, making them ideal for applications requiring precise thermal management.

Chemical Resistance

PTFE Teflon tubes offer exceptional resistance to a wide range of chemicals, including acids, bases, and solvents. This property makes them an excellent choice for transporting aggressive and corrosive substances without degrading or reacting. Such resistance is not limited to a few chemicals but extends across the spectrum, making PTFE tubes versatile for various chemical applications. Industries that require secure and reliable chemical transport often rely on PTFE tubing.

The inertness of PTFE means that it does not react with other substances, minimizing the risk of contamination and ensuring the purity of the transported medium. This is particularly important in industries like pharmaceuticals and food processing, where contamination can have serious consequences.

Non-Stick Properties

The non-stick nature of PTFE makes Teflon tubes particularly useful in applications where materials tend to adhere to surfaces. This feature is beneficial not only for maintaining the cleanliness of the system but also for improving efficiency. In industrial settings, this can lead to reduced downtime and maintenance, as substances easily flow through without causing blockages or buildup. The smooth inner surface of the tubes also facilitates easier cleaning processes, saving time and resources.

Furthermore, the non-stick property reduces friction, which can enhance the flow dynamics of fluids and gases. This can lead to improved energy efficiency and lower operational costs, as systems require less force to move substances through the tubing.

Flexibility and Durability

PTFE Teflon tubes are known for their flexibility, which allows them to be used in complex and tight spaces without the risk of kinking or breaking. This flexibility is essential in applications where tubing needs to navigate through intricate pathways. This flexibility, combined with their strength and durability, makes them a long-lasting solution for many industrial applications.

Their resistance to wear and tear means they can withstand repeated use and harsh conditions without significant degradation. This longevity is a critical factor in reducing maintenance costs and downtime, as systems do not require frequent replacement of tubing components.

Electrical Insulation

PTFE is an excellent electrical insulator, which adds another layer of versatility to its uses. Its dielectric properties make it a preferred choice in industries where electrical safety is paramount. In environments where electrical conductivity needs to be minimized, PTFE Teflon tubes serve as an effective barrier, making them ideal for use in the electrical and electronic industries.

This characteristic is particularly valuable in applications that involve high-frequency signals or sensitive electronic components, where any form of electrical interference could be detrimental. Additionally, PTFE’s resistance to environmental factors, such as moisture, further enhances its insulating capabilities.

Applications of PTFE Teflon Tubes

Automotive Industry

In the automotive industry, PTFE Teflon tubes are used in fuel systems, brake lines, and other components that require high temperature and chemical resistance. These tubes play a vital role in ensuring the safety and efficiency of vehicles. Their durability and flexibility make them suitable for the demanding conditions within vehicles. They are especially beneficial in environments where exposure to harsh chemicals or high temperatures is frequent.

Furthermore, PTFE tubes contribute to the overall performance of vehicles by optimizing fuel flow and ensuring the reliability of critical systems. Their resilience helps in reducing the frequency of maintenance and replacements, leading to cost savings and improved vehicle uptime.

Chemical Processing

The chemical industry benefits greatly from PTFE tubing due to its resistance to corrosive substances. Handling aggressive chemicals requires materials that can withstand harsh conditions without compromising safety or efficiency. These tubes are used in transport systems for chemicals, ensuring safety and longevity in processing plants. Their ability to maintain integrity under extreme chemical exposure makes them indispensable for chemical engineers.

Moreover, PTFE’s non-reactive nature ensures that the chemicals transported remain pure, which is crucial for maintaining the quality of chemical processes. This reliability in harsh conditions enhances the overall operational efficiency and safety of chemical processing facilities.

Food and Beverage Industry

In food processing, PTFE Teflon tubes are utilized for their non-stick and sanitary properties. Food safety is a top priority, and PTFE’s inert nature ensures that there are no unwanted chemical interactions. They ensure that food products do not adhere to the surfaces, maintaining cleanliness and hygiene. This is particularly important in processes involving sticky or viscous food substances.

Additionally, PTFE tubing is easy to clean, helping maintain high standards of sanitation required in the food and beverage industry. Its use minimizes the risk of contamination, ensuring that products meet regulatory standards and consumer expectations.

Medical and Pharmaceutical

In the medical and pharmaceutical industries, PTFE Teflon tubes are used for their biocompatibility and inertness. These properties are critical in environments where sterility and safety are essential. They are often found in equipment that requires sterile and non-reactive components, such as in drug delivery systems and medical devices.

The reliability of PTFE in maintaining purity and cleanliness makes it a trusted material in sensitive applications. It ensures that medical processes remain uncontaminated, safeguarding patient health and enhancing the effectiveness of pharmaceutical products.

PTFE Teflon Tubing vs. Other Materials

When comparing PTFE Teflon tubing to other materials, several factors stand out:

- Temperature Tolerance: Unlike rubber or PVC tubing, PTFE maintains its properties at much higher temperatures. This advantage allows it to be used in applications where other materials might fail, ensuring consistent performance under thermal stress.

- Chemical Compatibility: PTFE’s ability to resist aggressive chemicals makes it superior to metals and other plastics that may corrode or react. This chemical resilience ensures long-term reliability and safety in transporting hazardous substances.

- Longevity: The durability of PTFE Teflon tubes means they often have a longer lifespan, reducing the need for frequent replacements. This translates to cost savings and less environmental impact due to reduced waste.

Considerations When Choosing PTFE Teflon Tubing

While PTFE Teflon tubes offer many advantages, there are certain considerations to keep in mind:

- Cost: PTFE tubing can be more expensive than other materials. However, its longevity and performance often justify the initial investment. The long-term savings in maintenance and replacement costs can outweigh the higher upfront expense.

- Installation: Due to its stiffness, installation might require specialized fittings, particularly in applications involving complex routing. This could lead to additional labor costs, but the benefits of using PTFE often outweigh these challenges.

Conclusion

PTFE Teflon tubes stand out as a reliable and versatile option for many industrial applications. Their unique properties, including high-temperature tolerance, chemical resistance, and non-stick capabilities, make them indispensable in various sectors. Whether it’s for automotive, chemical processing, food and beverage, or medical industries, PTFE Teflon tubes provide a solution that ensures safety, efficiency, and longevity.

By understanding the advantages and applications of PTFE Teflon tubes, industries can make informed decisions to enhance their operations and achieve better outcomes. As technology and materials science advance, the potential uses for PTFE tubing are likely to expand, further solidifying its place as a critical component in industrial settings. Embracing PTFE technology means investing in reliability and the future of efficient industrial processes.