Polytetrafluoroethylene, commonly known as PTFE, is a versatile and highly durable material widely used in various industrial applications. Known for its non-stick properties and high chemical resistance, PTFE is a preferred choice for many industries, including chemical processing, pharmaceuticals, and food manufacturing. This article will help you understand PTFE pipe specifications and standards, along with the material’s unique properties.

PTFE, or Teflon as it is often branded, is a synthetic fluoropolymer of tetrafluoroethylene. It is renowned for its exceptional properties such as high heat resistance, low friction, and chemical inertness. These characteristics make PTFE an ideal material for pipes and fittings in environments where other materials might degrade or fail.

PTFE offers several key properties, including:

- High Temperature Resistance: PTFE can withstand temperatures up to 260°C (500°F), making it suitable for high-temperature applications. This resistance is crucial in environments where thermal stability is a priority, such as in heat exchangers and reactors.

- Chemical Resistance: It is inert to most chemicals, including acids and bases, ensuring durability in harsh environments. This property makes it indispensable in chemical processing industries where exposure to reactive substances is routine.

- Low Friction: PTFE’s low coefficient of friction makes it an excellent choice for applications requiring smooth, frictionless surfaces. This property is particularly useful in reducing wear and tear in mechanical systems, thereby extending their lifespan.

- Non-stick Surface: The non-reactive surface of PTFE prevents substances from adhering, which is crucial in many industrial processes. In the food industry, this property ensures that products do not stick to surfaces, maintaining purity and reducing waste.

When selecting PTFE pipes, understanding the specifications is crucial to ensure compatibility with your application. Here are some key specifications to consider:

Dimensions and Sizes

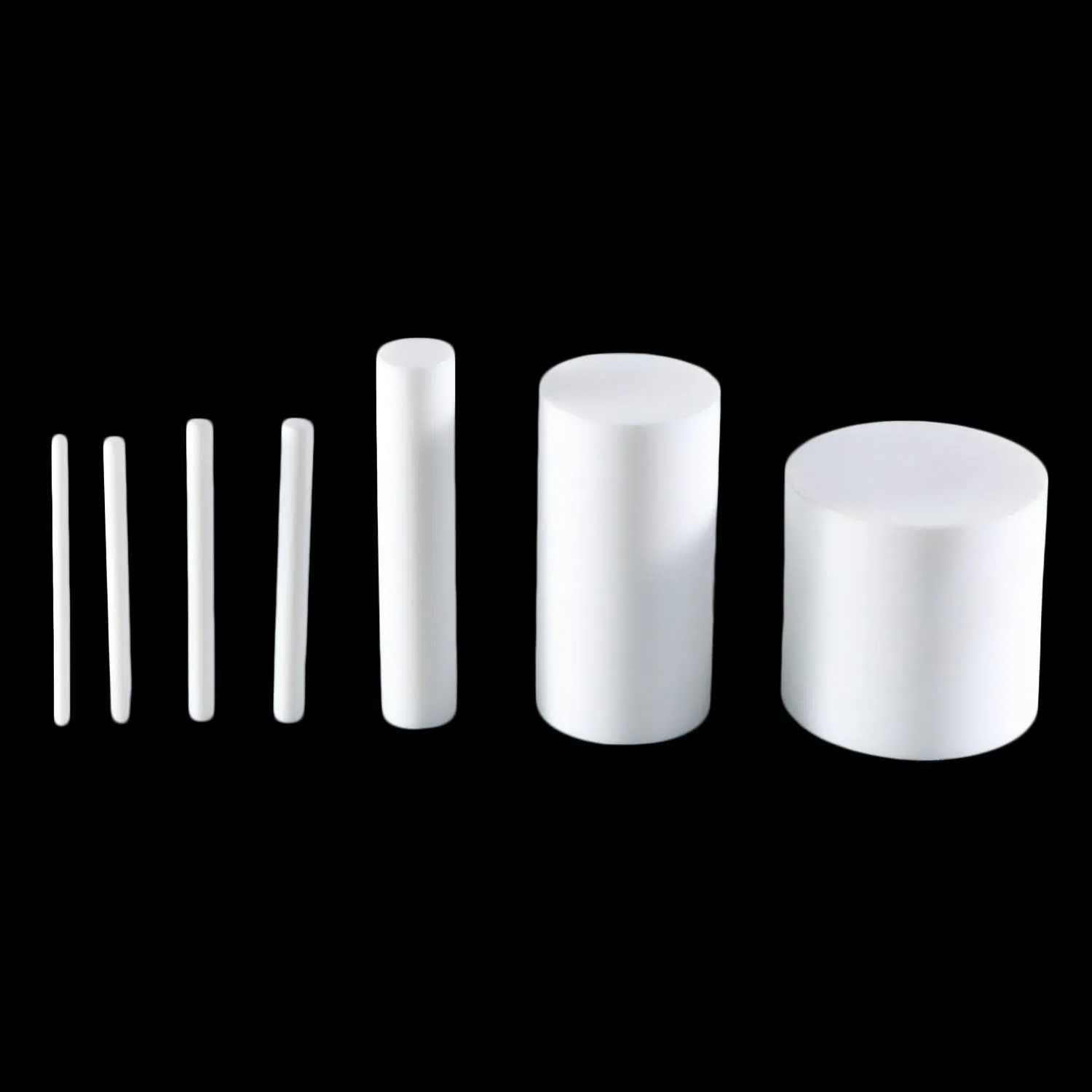

PTFE pipes come in various sizes and thicknesses to accommodate different industrial needs. Common PTFE pipe sizes range from small-diameter tubing to large-diameter pipes for heavy-duty applications. It’s important to select the appropriate size to ensure efficient flow and structural integrity.

The sizing of PTFE pipes is not just a matter of fitting them into existing systems; it’s about optimizing performance. A pipe that’s too small can lead to pressure drops and inefficiencies, while one that’s too large may be unnecessarily costly and cumbersome. Understanding the flow requirements and structural constraints of your application is essential for selecting the right pipe dimensions.

Lined Pipe Specification

PTFE-lined pipes are often used when added chemical resistance is needed. These pipes have a PTFE lining that provides a barrier against corrosive substances. The lining is typically bonded to a metal or composite pipe, offering strength and flexibility.

Lined pipes combine the strength of metals with the chemical resistance of PTFE, creating a hybrid solution that can withstand both mechanical stress and chemical attack. This makes them ideal for applications where both structural integrity and chemical resistance are paramount, such as in the transfer of aggressive chemicals in industrial settings.

PTFE Tubing Specification

PTFE tubing is often used in applications requiring flexible piping. It can be manufactured with different wall thicknesses and diameters to meet specific requirements. The tubing’s flexibility makes it ideal for applications where movement or bending is necessary.

The versatility of PTFE tubing extends beyond its physical flexibility; it also includes adaptability in various environments. Whether it’s used in laboratory settings for delicate experiments or in large-scale industrial processes, PTFE tubing can be customized to meet precise specifications, ensuring optimal performance in diverse applications.

Standards for PTFE Pipes

Understanding the relevant standards is essential when working with PTFE pipes. These standards ensure the quality and safety of the pipes in various applications.

ASTM Standards

The American Society for Testing and Materials (ASTM) has established standards for PTFE materials and products. These standards outline the testing methods and performance criteria for PTFE pipes, ensuring their reliability and safety in different applications.

ASTM standards are critical for maintaining consistency across manufacturers and ensuring that PTFE products meet rigorous quality benchmarks. Adhering to these standards helps in minimizing risks associated with product failure, thereby providing peace of mind to engineers and procurement specialists.

ISO Standards

The International Organization for Standardization (ISO) also provides guidelines for PTFE pipes. ISO standards cover aspects such as dimensions, tolerances, and testing methods, ensuring consistency and quality across different manufacturers and applications.

ISO standards play a pivotal role in facilitating international trade and cooperation, as they provide a unified framework that businesses worldwide can rely on. Compliance with these standards not only assures quality but also enhances the credibility of manufacturers in the global market.

Applications of PTFE Pipes

PTFE pipes are used in a wide range of industries due to their unique properties:

Chemical Processing

In chemical processing plants, PTFE pipes are used to transport corrosive chemicals safely. Their chemical resistance ensures long service life and minimal maintenance.

PTFE’s resilience against aggressive chemicals makes it an invaluable asset in maintaining operational integrity within chemical plants. By reducing the need for frequent replacements and repairs, PTFE pipes contribute to more efficient and cost-effective plant operations.

Food and Beverage Industry

PTFE’s non-stick and non-reactive properties make it ideal for food and beverage applications. PTFE pipes are used to transport food-grade materials without contamination.

In the food and beverage industry, maintaining purity and hygiene is paramount. PTFE pipes help ensure that products remain uncontaminated during transportation, thereby meeting stringent health and safety regulations. This is crucial for maintaining product quality and consumer trust.

Pharmaceutical Industry

In the pharmaceutical industry, PTFE pipes are used in applications requiring high purity and resistance to aggressive cleaning agents. They ensure the integrity of sensitive substances during production.

The pharmaceutical sector demands the highest levels of precision and cleanliness. PTFE pipes support these requirements by providing a sterile and inert pathway for critical processes, thereby safeguarding the purity and effectiveness of pharmaceutical products.

High-Temperature Applications

PTFE’s ability to withstand high temperatures makes it suitable for applications in industries such as aerospace and automotive, where heat resistance is crucial.

In high-temperature environments, the reliability of PTFE pipes ensures that systems continue to operate effectively under stress. This capability is particularly valuable in aerospace and automotive applications where performance and safety cannot be compromised.

Choosing the Right PTFE Pipe

When selecting PTFE pipes for your application, consider the following factors:

- Chemical Compatibility: Ensure the PTFE material is compatible with the chemicals it will be exposed to. This is vital to prevent degradation and ensure longevity.

- Temperature Requirements: Verify that the pipe can withstand the operating temperatures of your application. Proper temperature assessment prevents material failure and ensures consistent performance.

- Pressure Ratings: Check the pressure ratings to ensure the pipe can handle the system’s demands. Understanding pressure limitations is key to avoiding catastrophic failures in system operations.

- Regulatory Compliance: Ensure the pipes meet relevant industry standards and regulations. Compliance guarantees that the materials are fit for purpose and adhere to safety protocols.

Conclusion

PTFE pipes offer a combination of high chemical resistance, temperature tolerance, and non-stick properties, making them invaluable in various industrial applications. By understanding PTFE pipe specifications and standards, you can make informed decisions to select the right materials for your needs.

Whether you’re working in chemical processing, food production, or any other industry requiring reliable piping solutions, PTFE pipes provide a durable and efficient option. Ensure you consult relevant standards and specifications to achieve optimal performance and longevity in your applications.

An informed choice in selecting PTFE pipes not only enhances operational efficiency but also contributes to sustainable practices by reducing the need for frequent replacements. As industries continue to evolve, the role of PTFE in ensuring safe and efficient systems becomes even more critical, underscoring the importance of staying up-to-date with the latest standards and technologies.