When it comes to industrial applications, choosing the right tubing material is crucial. PTFE tubing, commonly known as Teflon tubing, stands out due to its impressive properties, particularly its temperature resistance. In this article, we will explore PTFE material properties, how temperature ratings work, and why PTFE is a preferred choice for high-temperature applications.

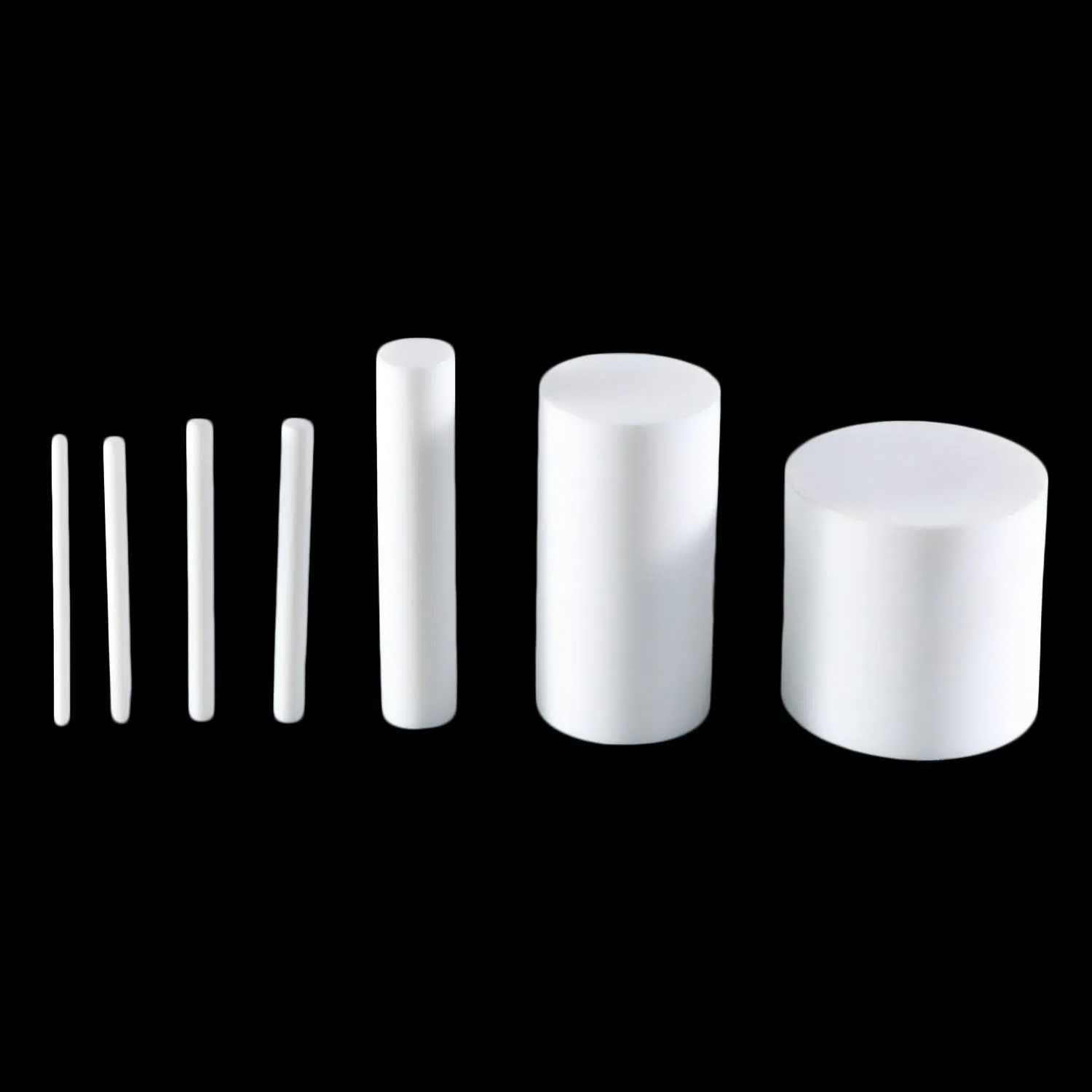

PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer known for its versatility. It’s used in a variety of applications due to its unique properties, which include non-reactivity, low friction, and high resistance to heat. PTFE tubing is widely used in industries such as chemical processing, aerospace, and electronics, where these properties are highly valued.

Key Properties of PTFE

PTFE’s material properties are what make it stand out. Here’s a quick look at some of the most notable ones:

- Non-Reactivity: PTFE is chemically inert, which means it doesn’t react with most substances. This makes it ideal for transporting chemicals.

- Low Friction: It has one of the lowest coefficients of friction of any solid, which means substances can move through PTFE tubing with ease.

- High-Temperature Resistance: PTFE can withstand extremely high temperatures, which we’ll dive into shortly.

- Electrical Insulation: It’s an excellent insulator, making it suitable for electronic applications.

- Non-Stick Surface: PTFE’s non-stick properties are why it’s used in cookware, but this also means materials do not easily adhere to PTFE tubing.

Temperature Rating of PTFE Tubing

Understanding the temperature rating of PTFE tubing is essential for ensuring its proper use in high-temperature applications.

What Does Temperature Rating Mean?

The temperature rating of a material refers to the range of temperatures that the material can withstand without degrading. For PTFE tubing, this means understanding both the upper and lower limits of temperature exposure.

PTFE Tubing Temperature Range

PTFE tubing is renowned for its ability to withstand a wide range of temperatures. Its temperature range typically spans from -328°F (-200°C) to 500°F (260°C). This makes it ideal for applications that involve extreme temperatures, whether hot or cold.

High-Temperature Resistance

One of the standout features of PTFE tubing is its resistance to high temperatures. At 500°F (260°C), PTFE maintains its properties, making it suitable for a variety of industrial processes that involve heat. This makes PTFE a leading choice for high-temperature tubing needs.

Low-Temperature Performance

On the flip side, PTFE also performs well in extremely low temperatures. This makes it versatile across different environments, from cryogenic applications to hot fluid transfer.

Why Choose PTFE Tubing for High-Temperature Applications?

Several factors make PTFE tubing the preferred choice for high-temperature applications.

Durability in Extreme Conditions

PTFE’s ability to maintain its properties under extreme conditions ensures it doesn’t degrade or lose functionality when exposed to harsh environments. This durability is crucial in industries where failure can result in significant downtime or hazards.

Chemical Resistance

PTFE’s chemical resistance means it won’t react with the substances it comes into contact with, even at high temperatures. This makes it ideal for transporting reactive or volatile chemicals safely.

Cost-Effectiveness

While PTFE might be more expensive than some other materials, its longevity and reliability in challenging conditions make it a cost-effective solution in the long run. The reduced need for replacements and repairs can offset the initial investment.

Versatility Across Industries

Due to its properties, PTFE tubing is used across various industries, including:

- Chemical Processing: For transporting aggressive chemicals without risk of reaction.

- Aerospace: In systems exposed to extreme temperatures and pressures.

- Electronics: As an insulator in high-temperature environments.

- Food and Beverage: For its non-stick and non-reactive properties.

Comparing PTFE with Other High-Temperature Tubing Materials

While PTFE is a top choice for many, it’s helpful to compare it with other materials to understand its advantages.

PTFE vs. Silicone

- Temperature Range: PTFE withstands higher temperatures than silicone, which typically maxes out around 450°F (232°C).

- Chemical Resistance: PTFE offers superior chemical resistance compared to silicone.

- Cost: Silicone is usually cheaper, but PTFE’s durability can make it more cost-effective over time.

PTFE vs. Metal Tubing

- Weight: PTFE is significantly lighter, which can reduce overall system weight.

- Corrosion Resistance: PTFE is non-reactive, while metals can corrode when exposed to certain chemicals.

- Flexibility: PTFE is more flexible than metal, allowing for easier installation and handling.

Conclusion

PTFE tubing’s impressive temperature range, coupled with its chemical resistance and durability, makes it an exceptional choice for high-temperature applications. Whether in chemical processing or aerospace, PTFE ensures reliability and performance where it matters most.

By understanding the temperature ratings and properties of PTFE, you can make an informed decision that meets your industrial tubing needs.

In conclusion, when it comes to high-temperature or chemically challenging environments, PTFE tubing stands out as a reliable and efficient solution. Its unique properties ensure that it meets the demands of various industries, providing both safety and efficiency in critical operations.