In the world of industrial applications, the choice of tubing material can significantly impact the efficiency and safety of operations. One such material that stands out for its exceptional properties is flexible PTFE tubing. Known for its versatility and durability, PTFE tubing is an invaluable asset across various industries. In this article, we will explore the benefits of using flexible PTFE tubing and why it might be the right choice for your needs.

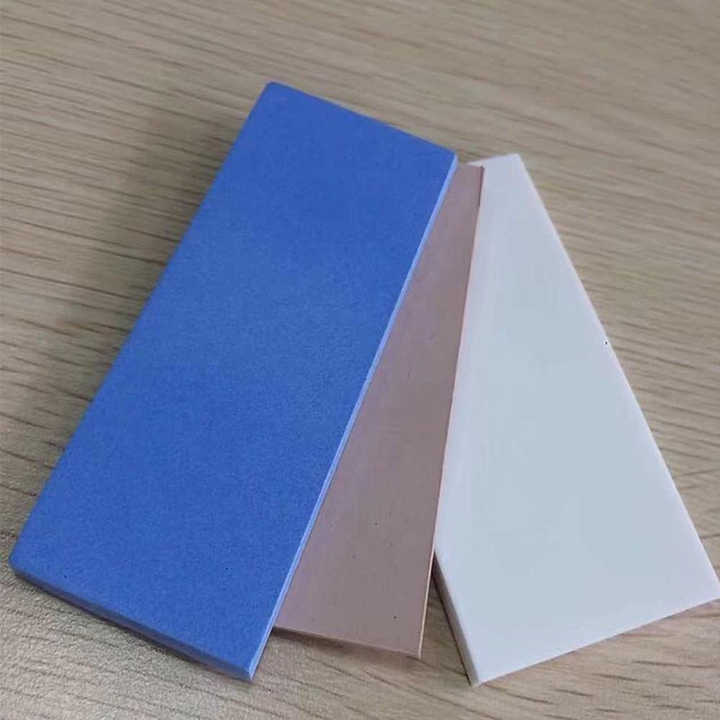

PTFE, or polytetrafluoroethylene, is a high-performance plastic known for its remarkable characteristics. It’s often recognized under the brand name Teflon. PTFE tubing is used extensively in industrial applications due to its non-stick, chemical-resistant, and high-temperature-resistant properties. This makes it an ideal choice for a range of demanding environments.

Key Benefits of Flexible PTFE Tubing

Chemical Resistance

One of the standout features of PTFE tubing is its resistance to a wide variety of chemicals. This property ensures that the tubing does not react or degrade when in contact with aggressive chemicals, making it suitable for chemical processing, laboratory applications, and handling corrosive substances. This chemical resistance extends the life of the tubing and reduces maintenance costs.

Non-Stick Properties

PTFE tubing is renowned for its non-stick surface, which means substances do not easily adhere to it. This characteristic is particularly beneficial in applications such as food processing or in situations where the prevention of material build-up is crucial. The non-stick nature also simplifies cleaning, contributing to more efficient operations.

High Temperature Resistance

PTFE tubing can withstand high temperatures up to 260°C (500°F), making it an excellent choice for applications involving extreme heat. This high temperature resistance enables it to perform effectively in environments where other materials might fail, thus providing reliability and safety in high-temperature operations.

Flexibility and Durability

Flexible PTFE tubing offers the advantage of being both pliable and robust. Its flexibility allows for easy installation in tight or complex spaces without the risk of kinking or cracking. Additionally, its durability ensures it can withstand mechanical stress, making it a long-lasting solution in dynamic environments.

Corrosion Resistance

In environments where exposure to corrosive materials is common, PTFE tubing’s corrosion resistance ensures longevity and reduces the risk of leakage or failure. This makes it a preferred choice in industries such as pharmaceuticals, petrochemicals, and water treatment.

Versatility in Applications

The unique properties of PTFE tubing make it suitable for a wide range of applications. Whether it’s used in automotive, aerospace, medical devices, or as part of a complex industrial system, PTFE tubing provides reliable performance and peace of mind.

In conclusion, flexible PTFE tubing offers a combination of chemical resistance, non-stick properties, high-temperature tolerance, and durability that is hard to match. For industries looking for a reliable solution to meet their tubing needs, PTFE stands out as a versatile and efficient option. Consider flexible PTFE tubing for your next project to ensure optimal performance and longevity.