Teflon PTFE tubing is a popular choice across various industries due to its remarkable properties. From chemical processing to automotive applications, this flexible and durable tubing is indispensable. But what makes Teflon PTFE tubing stand out from other materials? In this article, we’ll explore the key advantages of using Teflon PTFE tubing and why it might be the right choice for your needs.

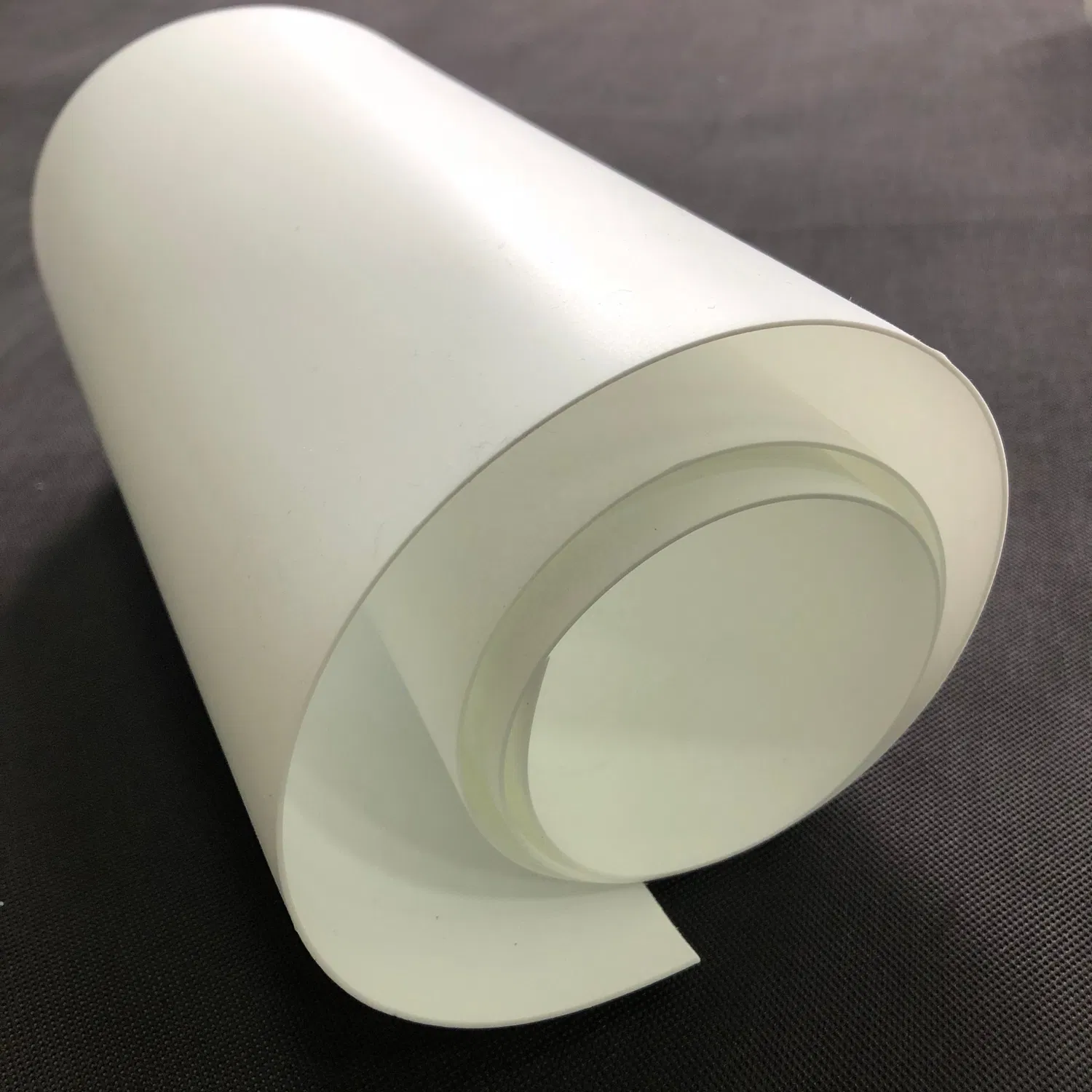

Teflon PTFE tubing is made from polytetrafluoroethylene (PTFE), a synthetic fluoropolymer of tetrafluoroethylene. PTFE is known for its exceptional non-stick properties, resistance to high temperatures, and chemical inertness. This makes Teflon PTFE tubing an ideal choice for a wide range of applications that demand durability and reliability.

Key Advantages of Teflon PTFE Tubing

Exceptional Chemical Resistance

One of the most outstanding features of Teflon PTFE tubing is its unparalleled chemical resistance. It can withstand exposure to almost all types of chemicals, including acids, bases, and solvents, without being damaged. This makes it an excellent choice for industries like chemical processing, pharmaceuticals, and food processing, where tubing may come into contact with harsh substances.

High-Temperature Tolerance

Teflon PTFE tubing can endure extreme temperatures, ranging from as low as -328°F (-200°C) to as high as 500°F (260°C). This high-temperature tolerance makes it suitable for applications that involve significant heat exposure, such as automotive and aerospace industries.

Non-Stick Properties

The non-stick surface of Teflon PTFE tubing prevents materials from adhering to its walls. This feature is particularly useful in applications where a clean and smooth flow is essential, such as in food and beverage processing or medical equipment.

Flexibility and Durability

Teflon PTFE tubing is renowned for its flexibility and durability. It can be bent and twisted without losing its shape or functionality, which makes it an ideal choice for applications that require maneuverability. Its durability ensures a long service life, reducing the need for frequent replacements and maintenance.

Electrical Insulation

PTFE is an excellent electrical insulator, making Teflon PTFE tubing suitable for use in electrical and electronic applications. It can withstand high voltages and offers protection against electrical interference, ensuring the safe and efficient operation of electrical systems.

Low Friction Coefficient

Teflon PTFE tubing has a low coefficient of friction, which means it allows for smooth and easy movement of fluids and gases. This property is beneficial in reducing energy consumption and wear and tear in systems that involve the transportation of materials.

Applications of Teflon PTFE Tubing

Chemical Processing Industry

In the chemical processing industry, Teflon PTFE tubing is used to transport aggressive chemicals safely. Its chemical resistance ensures that it won’t degrade or contaminate the substances being transported.

Automotive and Aerospace Industries

In automotive and aerospace applications, the high-temperature tolerance and flexibility of Teflon PTFE tubing are invaluable. It is often used in fuel lines, brake systems, and hydraulic systems where reliable performance is critical.

Food and Beverage Industry

The non-stick and chemical-resistant properties of Teflon PTFE tubing make it ideal for use in the food and beverage industry. It is commonly used in processing equipment and dispensing systems to ensure cleanliness and prevent contamination.

Medical and Pharmaceutical Fields

In the medical and pharmaceutical fields, Teflon PTFE tubing is used in a variety of applications, including drug delivery systems, laboratory equipment, and surgical instruments. Its biocompatibility and chemical resistance make it a preferred choice for these sensitive applications.

Electrical and Electronic Applications

As an excellent insulator, Teflon PTFE tubing is used to protect wires and cables in electrical and electronic applications. It prevents electrical interference and ensures the safe operation of electronic devices.

Custom PTFE Products for Specific Needs

Many manufacturers offer custom PTFE products, allowing businesses to tailor Teflon PTFE tubing to their specific requirements. Customization options may include different sizes, wall thicknesses, and colors, as well as additional features like anti-static properties or reinforced walls for added strength.

Conclusion

Teflon PTFE tubing is a versatile and reliable solution for a wide range of industrial applications. Its exceptional chemical resistance, high-temperature tolerance, flexibility, and durability make it an ideal choice for industries ranging from chemical processing to food and beverage production. Whether you’re looking for standard or custom PTFE products, Teflon PTFE tubing offers the performance and reliability you need to ensure the success of your operations.

By understanding the advantages and applications of Teflon PTFE tubing, you can make an informed decision about whether it’s the right material for your needs. Whether you require a high-temperature PTFE tube, industrial PTFE hose, or flexible Teflon tubing, this material is designed to meet the demands of today’s challenging environments.

Consider consulting with a supplier to discuss the specific requirements of your project and explore the range of options available. With the right choice of Teflon PTFE tubing, you can enhance the efficiency, safety, and reliability of your systems.