When it comes to sealing pipe threads, especially in plumbing and DIY projects, PTFE thread seal tape, often referred to as Teflon tape, is a crucial tool. It acts as a sealant, preventing leaks by filling the gaps between threaded PVC pipes and fittings. This article will explore the effective use of PTFE thread seal tape on PVC, including the benefits, proper application techniques, and common misconceptions.

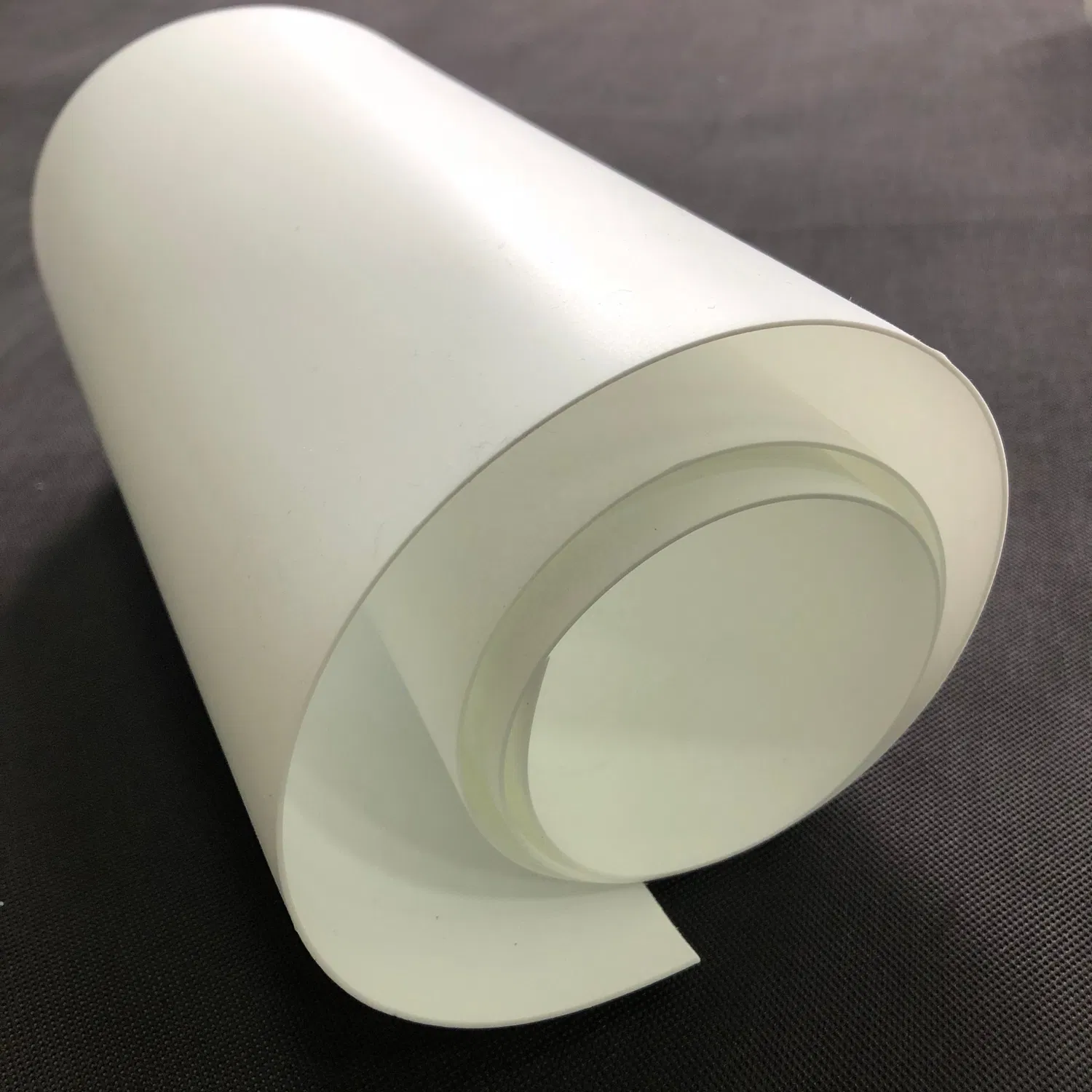

PTFE (Polytetrafluoroethylene) thread seal tape is a non-adhesive tape commonly used in plumbing to seal pipe threads. It’s made from a strong, flexible material that withstands heat and chemical exposure. PTFE tape is highly versatile and can be used on plastic pipes, metal fittings, and more.

Benefits of Using PTFE Tape

- Prevents Leaks: The primary purpose of PTFE tape is to prevent leaks. It works by filling the tiny gaps between pipe threads, ensuring a tight seal.

- Easy to Use: PTFE tape is straightforward to apply, even for beginners. It requires no additional tools or adhesives.

- Versatility: Suitable for a variety of materials, PTFE tape is compatible with PVC, metal, and other types of pipes.

- Temperature Resistance: It can withstand a wide range of temperatures, making it ideal for both hot and cold water systems.

- Chemical Resistance: PTFE tape is resistant to many chemicals, ensuring a long-lasting seal.

Applying PTFE Thread Seal Tape on PVC

Proper application of PTFE tape is essential for effective sealing. Here’s a step-by-step guide on how to apply PTFE tape on PVC pipes:

Step 1: Clean the Threads

Before applying the tape, ensure that the threads are clean and dry. Remove any dirt, oil, or old sealant from the threads to ensure the tape adheres properly.

Step 2: Wrap the Tape

Hold the tape in one hand and the pipe in the other. Start wrapping the tape around the male threads of the pipe, beginning at the end of the pipe and working towards the center. Wrap the tape in the direction of the threads – typically clockwise.

Step 3: Apply the Right Number of Layers

Use 3-4 layers of PTFE tape for a tight seal. Too few layers might not provide adequate sealing, while too many layers can make it difficult to screw the fittings together.

Step 4: Smooth the Tape

After wrapping, smooth the tape onto the threads with your fingers. This step ensures the tape conforms to the thread pattern and provides a better seal.

Step 5: Assemble the Fittings

Once the tape is applied, screw the fittings together. The tape will fill the gaps between the threads, creating a watertight seal.

Common Misconceptions about PTFE Tape

Despite its widespread use, there are several misconceptions about PTFE thread seal tape:

Myth 1: PTFE Tape is Adhesive

PTFE tape is not adhesive. It seals by filling gaps rather than sticking to surfaces. Its effectiveness comes from its ability to compress and conform to the threads.

Myth 2: More Tape is Always Better

While it’s important to use enough tape for a secure seal, overwrapping can cause issues. Excessive tape can make it difficult to assemble fittings or even cause leaks by preventing a proper fit.

Myth 3: PTFE Tape is Only for Metal Pipes

PTFE tape is versatile and can be used on various pipe materials, including PVC. However, it’s crucial to apply it correctly to prevent leaks and ensure a secure fit.

Alternatives to PTFE Tape

While PTFE tape is a popular choice, other sealants can also be effective for PVC pipes:

Pipe Dope

Also known as pipe joint compound, pipe dope is a paste-like substance applied to pipe threads. It provides a reliable seal and is often used in high-pressure applications.

Anaerobic Sealants

These liquid sealants cure in the absence of air, providing a strong bond. They’re often used in industrial settings where a permanent seal is required.

Teflon Paste

Similar to pipe dope, Teflon paste is applied to threads and offers a reliable seal. It’s thicker than PTFE tape and can be more effective in certain applications.

When to Use PTFE Tape on PVC

PTFE tape is best used in low-pressure applications, such as residential plumbing systems. It’s ideal for sealing threaded PVC connections in water supply lines, irrigation systems, and other non-critical applications.

High-Pressure Applications

For high-pressure applications, consider using a more robust sealant, like pipe dope or anaerobic sealants, to ensure a reliable, long-lasting seal.

Conclusion

PTFE thread seal tape is an essential tool for sealing PVC pipe threads. It’s easy to apply, versatile, and effective at preventing leaks. By understanding how to properly use PTFE tape and recognizing its limitations, you can ensure secure and leak-free connections in your plumbing projects.

Whether you’re a DIY enthusiast or a professional plumber, mastering the use of PTFE tape will enhance your skills and help you achieve better results in your work. Always choose the right sealant for the job, and don’t hesitate to explore alternative options when necessary. With the right approach, you’ll achieve leak-free, long-lasting connections every time.