In industrial and electrical applications, choosing the right tubing material can make a significant difference in performance and longevity. Heat-shrinkable PTFE tubing, also known as Teflon heat shrink tube, is a standout choice due to its unique properties and versatility. Let’s explore the benefits of using this high-performance material.

One of the most notable features of PTFE heat shrink tubing is its ability to withstand extreme temperatures. With a melting point of around 327°C (621°F), PTFE tubing can operate effectively in both high-heat and low-temperature environments. This makes it ideal for applications requiring high-temperature shrink tubing, such as in aerospace, automotive, and industrial sectors.

Chemical Resistance

PTFE tubing is renowned for its chemical-resistant properties. It can resist a wide range of corrosive substances, including acids, solvents, and bases, making it indispensable for industries that deal with hazardous chemicals. This chemical resistance ensures longevity and reliability, reducing the need for frequent replacements.

Electrical Insulation

Another key benefit of PTFE heat shrink tubing is its exceptional electrical insulation capabilities. It is often used in electrical applications to protect wires and connections from electrical interference, moisture, and abrasion. This fluoropolymer shrink tube is an excellent choice for ensuring safety and maintaining the integrity of electrical systems.

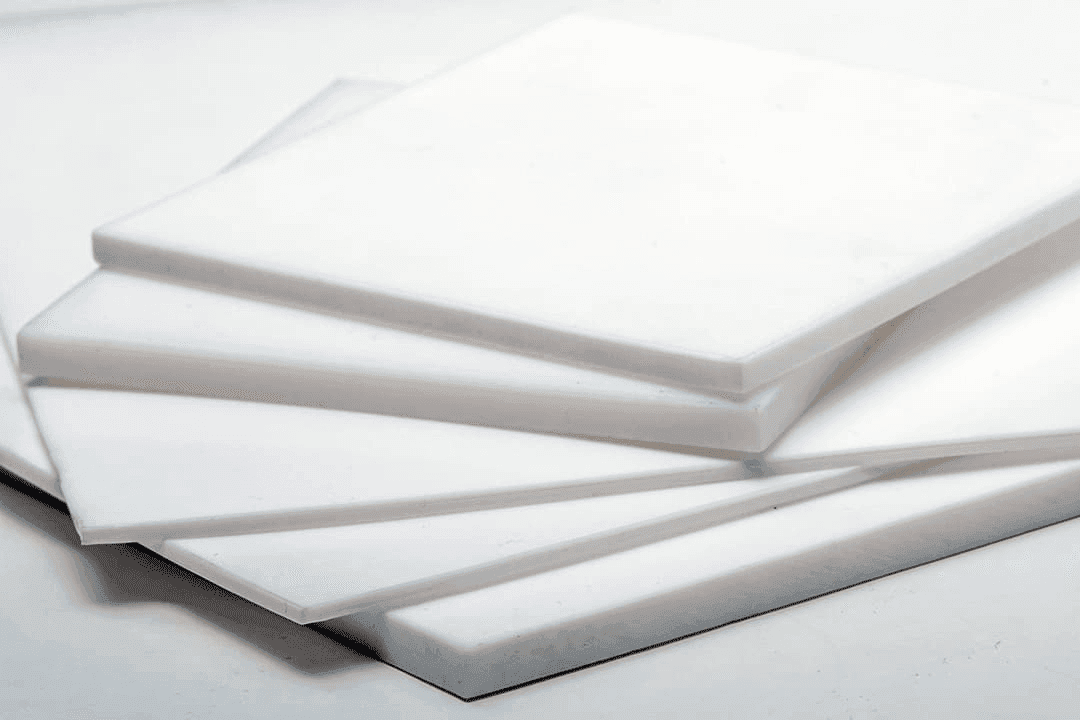

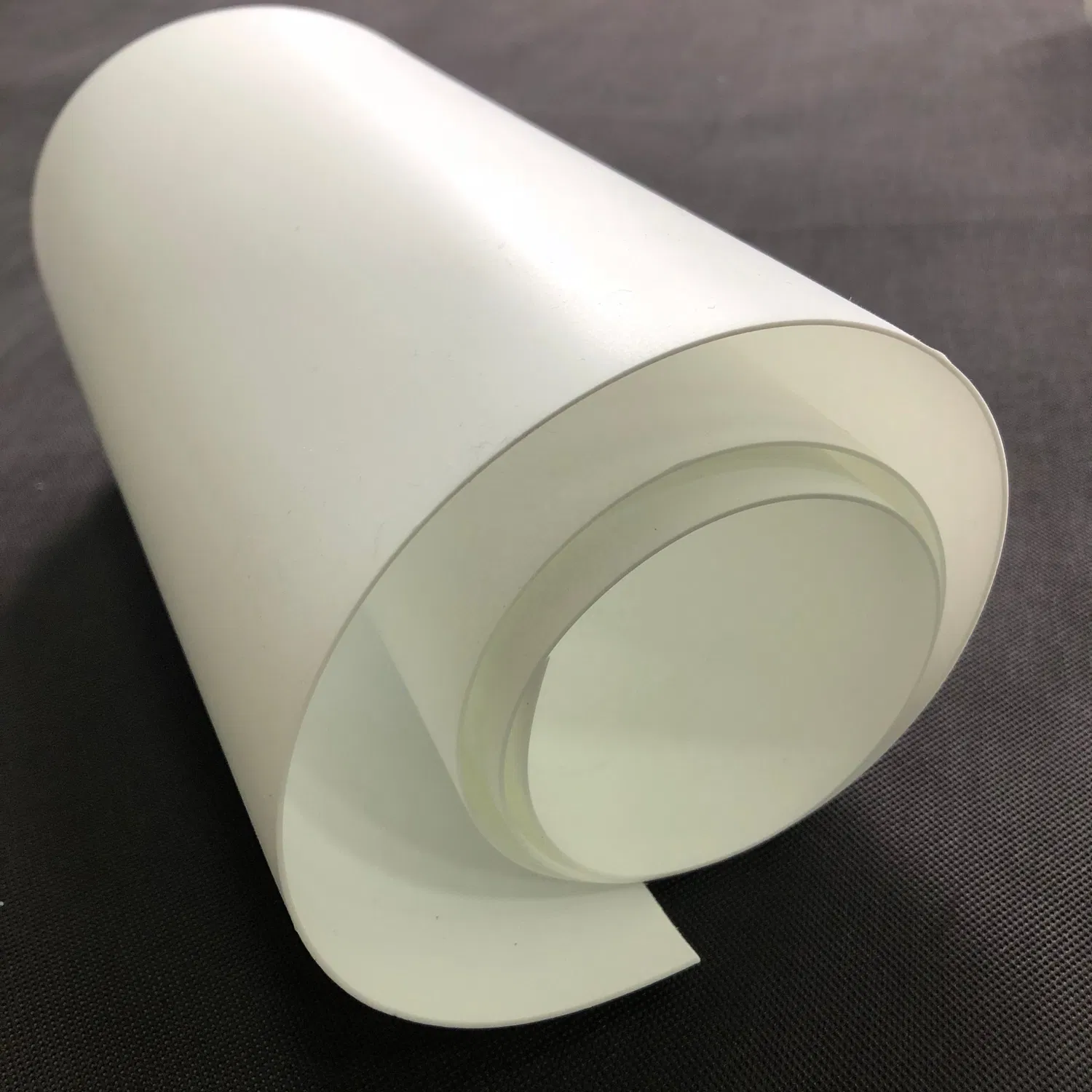

Versatility and Flexibility

PTFE’s versatility is reflected in its wide range of applications. From providing a protective sleeve for delicate components to serving as an insulating layer for wires, PTFE tubing is highly adaptable. Its flexibility allows it to conform to irregular shapes and sizes, providing a snug fit and robust protection.

Durability and Longevity

Durability is a critical factor in choosing the right tubing, and PTFE does not disappoint. Its resistance to wear and tear, coupled with its robustness against environmental factors, makes it a durable choice for long-term applications. This durability translates to cost-effectiveness, as it minimizes the need for repairs and replacements over time.

Non-Stick Properties

PTFE tubing is known for its non-stick surface, which prevents the accumulation of residues on its surface. This feature is particularly beneficial in applications where cleanliness and hygiene are paramount, such as in food processing and medical equipment.

Conclusion

Heat-shrinkable PTFE tubing offers a plethora of benefits, from its remarkable temperature and chemical resistance to its electrical insulation properties. Its versatility, durability, and non-stick nature make it a preferred choice across various industries. Whether you are looking for a reliable solution for high-temperature applications or need a robust chemical-resistant tubing, PTFE heat shrink tubing is a choice that promises performance and reliability.

By incorporating PTFE tubing into your projects, you can ensure enhanced protection, efficiency, and longevity. Consider exploring this innovative solution for your next application to experience these benefits firsthand.