Spiral wound gaskets are composed of a mixture of metal and filler materials. They are designed to withstand high pressure and extreme temperatures, making them ideal for challenging industrial environments. The structure of these gaskets typically consists of a metal strip wound in a spiral fashion with a filler material between the layers. This unique construction allows the gaskets to maintain their integrity under significant stress, providing a durable and reliable seal.

The combination of materials used in spiral wound gaskets offers a balance between strength and flexibility. The metal component provides structural support, while the filler material accommodates surface irregularities, ensuring a tight seal. This construction method not only enhances the gasket’s resilience but also allows it to recover its shape after compression, which is vital for maintaining a consistent seal over time.

What is PTFE?

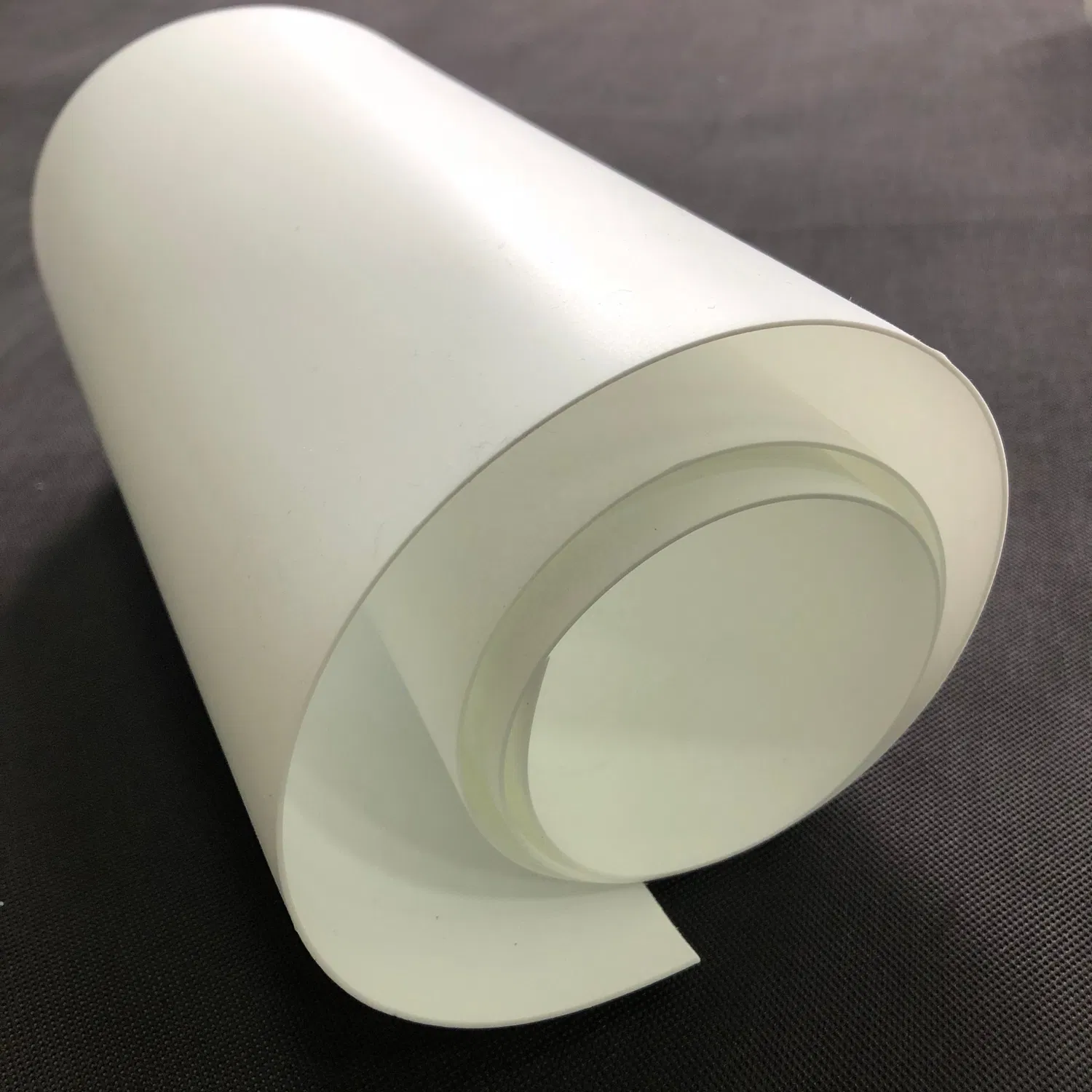

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer known for its non-stick properties and chemical resistance. It’s most famously known under the brand name Teflon. PTFE is used in various applications, including cookware, electrical insulation, and gaskets. Its unique characteristics make it an ideal filler material for spiral wound gaskets. PTFE’s ability to resist chemical reactions and high temperatures without degrading makes it a valuable asset in harsh environments.

Beyond its non-stick nature, PTFE’s low coefficient of friction reduces wear and tear on mechanical components, extending their lifespan. This characteristic is particularly beneficial in dynamic sealing applications where movement between surfaces is involved. As a filler material, PTFE enhances the gasket’s adaptability to different sealing surfaces, accommodating slight imperfections and ensuring a secure fit.

Benefits of PTFE Filled Spiral Wound Gaskets

1. Exceptional Chemical Resistance

One of the most notable advantages of PTFE filled spiral wound gaskets is their excellent chemical resistance. PTFE is inert to almost all chemicals, making these gaskets suitable for a wide range of applications, including those involving aggressive chemicals and corrosive environments. This property is particularly beneficial in industries like chemical processing, oil and gas, and pharmaceuticals, where exposure to harsh chemicals is common. PTFE’s chemical inertness ensures that the gaskets maintain their integrity and do not contribute to contamination or degradation of the system.

The ability to resist chemical attack means these gaskets can be used in environments where other materials might fail. This durability translates to fewer replacements and reduced maintenance costs, enhancing the efficiency of industrial operations. Moreover, the non-reactive nature of PTFE prevents it from interacting with the substances it comes into contact with, ensuring the purity of processes, which is crucial in industries like food and pharmaceuticals.

2. High Temperature and Pressure Tolerance

PTFE filled spiral wound gaskets are designed to perform under extreme temperature and pressure conditions. They can withstand temperatures ranging from -200°C to 260°C (-328°F to 500°F) and pressures up to 3000 psi. This makes them a reliable choice for industries where such conditions are prevalent, such as power generation and petrochemical industries. The ability to endure such extremes without compromising the seal integrity is a testament to the robust design and material composition of these gaskets.

The gaskets’ resilience to thermal cycling—rapid temperature changes—ensures that they can maintain a seal even as materials expand and contract. This adaptability is critical in applications involving fluctuating temperatures, preventing leaks and ensuring consistent performance. Additionally, their pressure resistance makes them suitable for high-pressure applications, where maintaining a leak-free environment is essential for safety and efficiency.

3. Versatility and Flexibility

The versatility of PTFE filled spiral wound gaskets is another significant advantage. They can be customized to fit various flange sizes and shapes, including the standard PTFE gasket inside diameter of 3 inches. This adaptability ensures a perfect fit and optimal sealing for different applications. Additionally, the flexibility of PTFE allows for easy installation and removal, reducing downtime during maintenance. This customization capability is vital for operations requiring precision and reliability in sealing solutions.

The flexibility of PTFE not only simplifies installation but also accommodates minor misalignments between surfaces, ensuring a comprehensive seal. This adaptability is particularly valuable in dynamic systems where components may shift or vibrate during operation. The ability to easily remove and replace the gaskets also supports routine maintenance, allowing for quick inspections and replacements without significant downtime.

4. Non-Stick Surface

PTFE’s non-stick properties are advantageous in applications where easy removal and replacement of gaskets are necessary. The non-stick surface prevents the gasket from adhering to the flange surfaces, minimizing damage during disassembly and ensuring a longer lifespan for both the gasket and the flanges. This feature is particularly beneficial in industries where equipment must be regularly disassembled for cleaning or inspection.

The non-stick characteristic of PTFE also reduces the risk of residue buildup on the gasket, which can compromise the seal over time. This property ensures that the gasket remains effective for longer periods, reducing the need for frequent replacements. Furthermore, the ease of removal supports quick maintenance cycles, enhancing overall operational efficiency by minimizing downtime.

5. Stainless Steel Inner Ring

Many PTFE filled spiral wound gaskets come with a stainless steel inner ring. This ring enhances the structural integrity of the gasket, providing additional support and preventing blowouts. The combination of stainless steel and PTFE ensures that the gasket can handle thermal cycling without losing its sealing capabilities. The inner ring acts as a reinforcement, ensuring that the gasket maintains its shape and seal under pressure.

The presence of a stainless steel inner ring also contributes to the gasket’s durability, allowing it to withstand mechanical stresses and vibrations. This feature is particularly important in high-pressure applications where the risk of blowouts must be minimized. By providing a robust framework, the inner ring ensures that the gasket can maintain a secure seal even under challenging conditions, enhancing the overall safety and reliability of industrial systems.

Applications of PTFE Filled Spiral Wound Gaskets

PTFE filled spiral wound gaskets are used in a variety of industries due to their excellent performance characteristics. Some common applications include:

- Chemical Processing: Ideal for sealing pipes and equipment that handle aggressive chemicals. The chemical inertness of PTFE ensures that the gaskets do not react with the substances they seal, maintaining process integrity.

- Oil and Gas: Used in pipelines and refineries where high temperatures and pressures are common. The gaskets’ ability to withstand harsh conditions ensures reliable sealing in critical applications, preventing leaks and ensuring safety.

- Pharmaceuticals: Suitable for clean environments due to their non-contaminating properties. The purity and non-reactive nature of PTFE ensure that these gaskets meet stringent hygiene standards required in pharmaceutical manufacturing.

- Power Generation: Used in turbines and other equipment exposed to extreme conditions. Their resilience to high temperatures and pressures makes them an ideal choice for ensuring the efficient and safe operation of power generation equipment.

Selecting the Right PTFE Filled Spiral Wound Gasket

When selecting a PTFE filled spiral wound gasket, several factors should be considered to ensure optimal performance:

1. Operating Conditions

Evaluate the temperature, pressure, and chemical exposure conditions of your application to determine the appropriate gasket specification. Ensure that the gasket can withstand the maximum conditions it will encounter. This evaluation is crucial for ensuring that the gasket performs reliably under all expected operational scenarios.

Understanding the specific requirements of your application allows for the selection of a gasket that not only meets but exceeds the necessary performance criteria. This proactive approach helps prevent potential failures and extends the lifespan of the equipment, contributing to overall operational efficiency.

2. Flange Type and Size

Identify the flange type and size to select a gasket with the correct dimensions. Customizations, such as a stainless inner ring with PTFE gasket, can be made to meet specific requirements. Ensuring a precise fit is vital for achieving an effective seal and preventing leaks.

Proper sizing and fitting are essential for maintaining the integrity of the seal over time. An accurately sized gasket reduces the risk of blowouts and leaks, ensuring that the system operates smoothly and safely. Customization options further enhance the gasket’s ability to meet the unique demands of specific applications.

3. Installation and Maintenance

Consider the ease of installation and maintenance. Choose a gasket that can be installed and removed without causing damage to the flange surfaces, reducing downtime and maintenance costs. The simplicity of the installation process can significantly impact operational efficiency and reduce labor costs.

Selecting a gasket that supports quick and easy maintenance not only minimizes downtime but also extends the lifespan of the equipment. By facilitating efficient maintenance practices, these gaskets help ensure continuous operation and reduce the frequency of costly repairs and replacements.

Conclusion

PTFE filled spiral wound gaskets offer numerous advantages, making them a preferred choice for many industrial applications. Their exceptional chemical resistance, high-temperature and pressure tolerance, versatility, and non-stick properties ensure reliable sealing in even the most challenging environments. By selecting the right PTFE filled spiral wound gasket for your application, you can enhance the performance and longevity of your equipment while minimizing maintenance costs.

In conclusion, whether you are dealing with aggressive chemicals, extreme temperatures, or high-pressure environments, a PTFE filled spiral wound gasket is an investment in performance and reliability. These gaskets not only provide effective sealing solutions but also contribute to the overall efficiency and safety of industrial operations. Their adaptability and durability make them a wise choice for any industry seeking reliable and long-lasting sealing solutions.