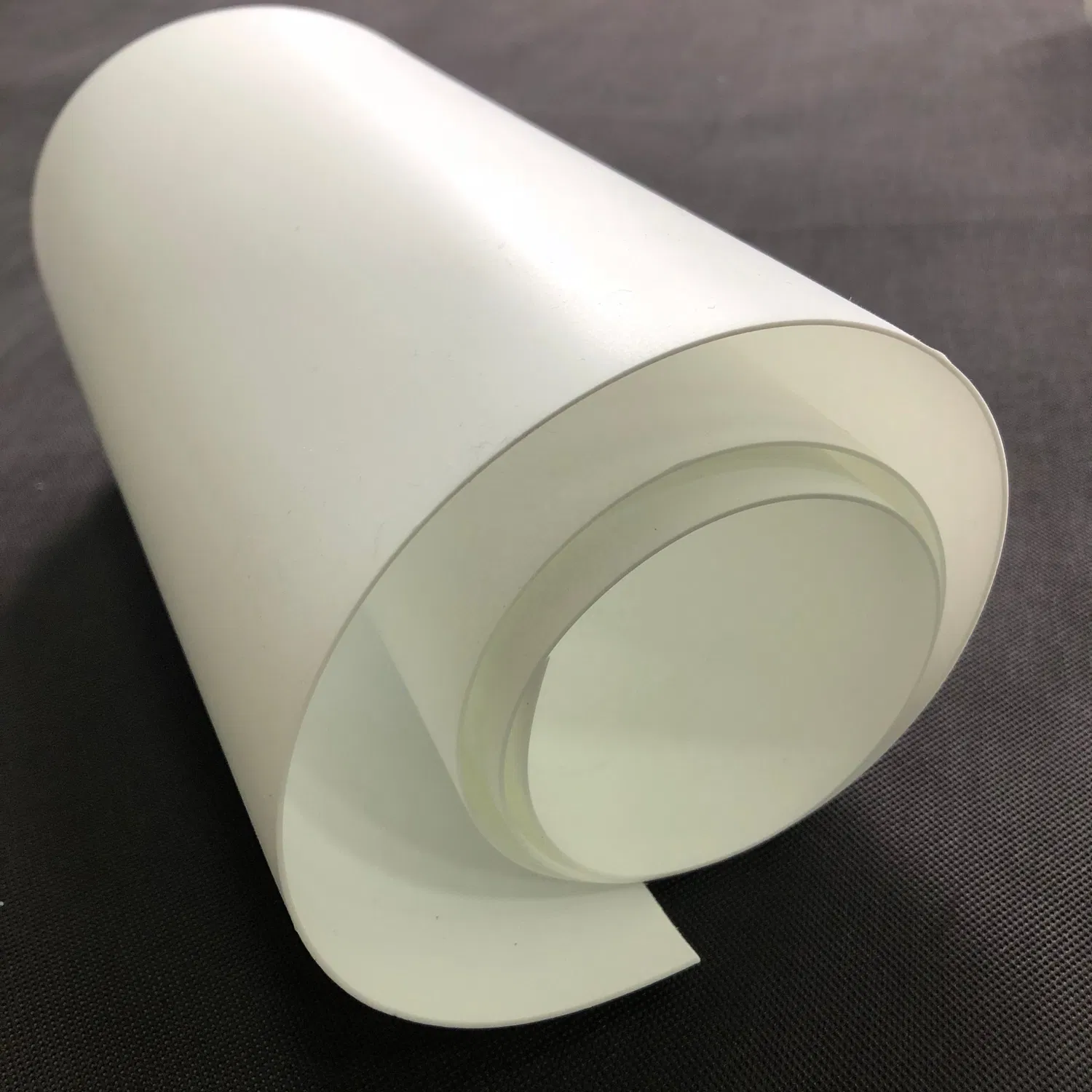

In the world of electrical engineering and industrial applications, choosing the right wire insulation is crucial. PTFE wire insulation tubes, also known as Teflon protective tubing, offer numerous advantages that make them a preferred choice for many professionals. Let’s explore the benefits of using PTFE electrical tubing.

One of the most significant advantages of PTFE wire insulation tubes is their exceptional chemical resistance. This chemical-resistant wire sleeve can withstand exposure to a wide range of substances, including acids, bases, and solvents. This makes PTFE tubing ideal for environments where wires are likely to come into contact with corrosive materials.

High-Temperature Tolerance

PTFE heat-resistant tubes can endure extreme temperatures, making them perfect for high-temperature wire protection. With the ability to withstand temperatures up to 260°C (500°F), PTFE cable insulation ensures that the wires remain functional and safe even in the most demanding conditions. This makes PTFE insulated tubing a go-to option for industries like aerospace, automotive, and electronics, where high temperatures are a common challenge.

Excellent Electrical Insulation

Teflon wire insulation provides superior electrical insulation properties. It is non-conductive, which helps to prevent electrical leakage and ensures the safety and efficiency of electrical systems. This makes PTFE wire insulation tubes an excellent choice for applications where electrical insulation is of utmost importance.

Flexibility and Durability

PTFE tubing is known for its flexibility and durability. It can be bent and twisted without losing its structural integrity, which makes it suitable for applications where wires need to navigate through tight spaces or around obstacles. Additionally, PTFE’s resistance to cracking and degradation over time ensures that it provides long-lasting protection.

Versatility in Applications

PTFE heat shrink tubing is incredibly versatile and can be used in a wide range of applications. From industrial wire insulation to specialized uses in medical equipment, PTFE tubing is a reliable solution. Its heat-shrink capability allows it to conform tightly to the wire, providing a snug fit and additional mechanical protection.

Low Friction Surface

Another notable advantage of PTFE wire insulation tubes is their low-friction surface. This property reduces wear and tear on the wires, prolonging their lifespan. It also makes PTFE tubing easier to install and remove, which is a significant benefit in applications where maintenance and repairs are frequent.

In conclusion, PTFE wire insulation tubes offer a host of benefits that make them an ideal choice for various industrial and electrical applications. Their chemical resistance, high-temperature tolerance, excellent electrical insulation, flexibility, and durability make them a wise investment for ensuring the safety and efficiency of your wiring systems. Whether you’re dealing with harsh chemical environments or high-temperature settings, PTFE tubing provides the protection and reliability you need.

For those looking to optimize their wiring systems, PTFE insulated tubing is a choice you won’t regret. Consider incorporating this versatile and robust solution into your projects for enhanced performance and safety.