In the realm of industrial materials, few products match the versatility and utility of Teflon PTFE tubing. As a durable, flexible, and reliable option, custom Teflon PTFE tubing is a game-changer for many industries. This article explores the myriad benefits and applications of bespoke PTFE tubing, shedding light on why it’s a preferred choice for businesses worldwide.

What is PTFE?

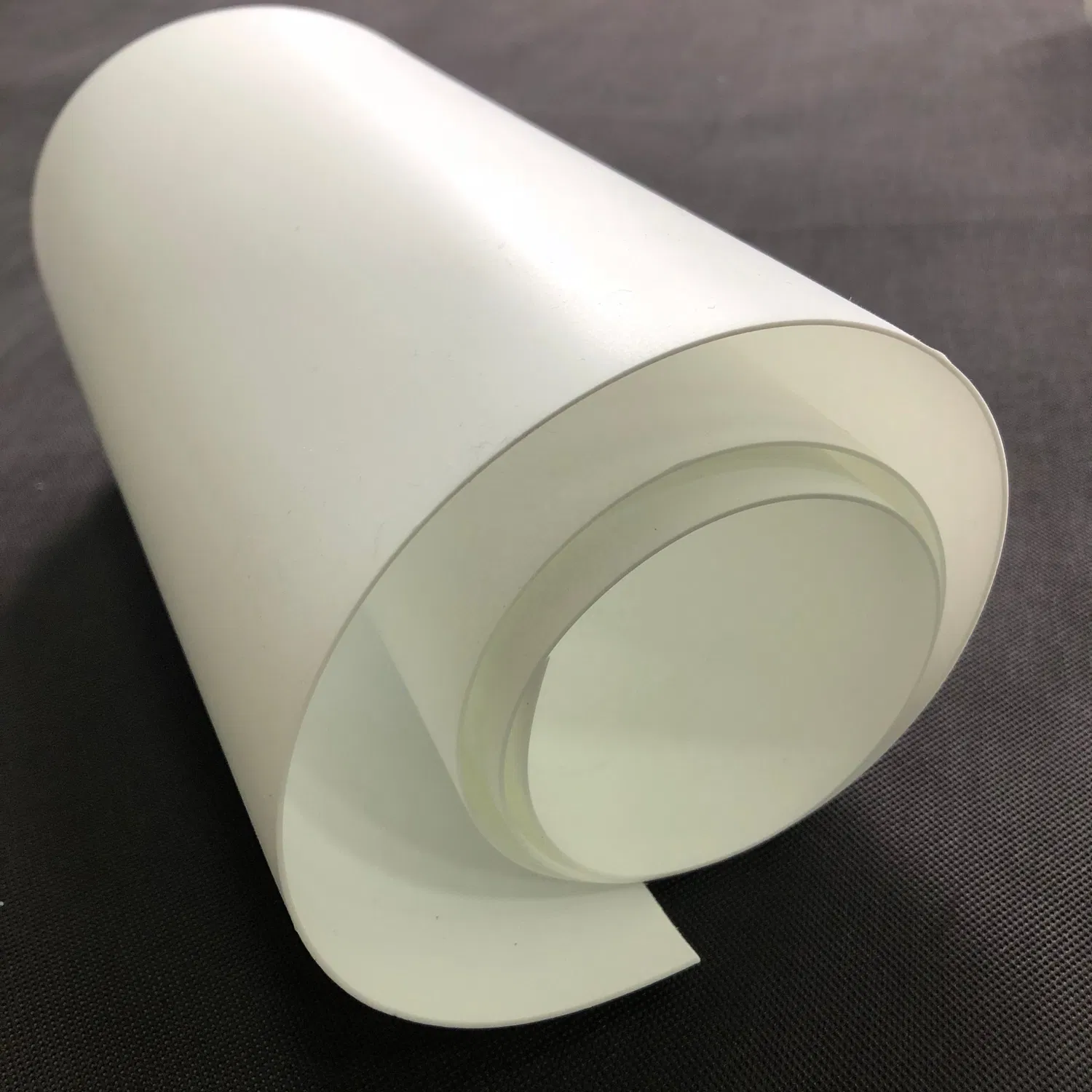

Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer known for its non-stick properties and resistance to high temperatures, chemicals, and electrical conductivity. Teflon is the brand name for PTFE, and it is widely used due to its remarkable characteristics, particularly in applications requiring a non-reactive and frictionless surface.

Why Choose Custom PTFE Tubing?

Custom PTFE tubing allows businesses to tailor the product to their specific needs. Whether it’s altering the diameter, wall thickness, or length, custom solutions ensure that the tubing meets precise requirements, enhancing performance and efficiency.

Benefits of Custom Teflon PTFE Tubing

Outstanding Chemical Resistance

One of the standout features of Teflon PTFE tubing is its exceptional chemical resistance. This makes it ideal for industries dealing with aggressive chemicals, as it can withstand exposure without degrading or reacting.

High-Temperature Tolerance

Teflon PTFE tubing can endure extreme temperatures, ranging from -450°F to 500°F (-268°C to 260°C), without losing its structural integrity. This makes it suitable for applications in harsh environments where other materials might fail.

Non-Stick Properties

The non-stick surface of PTFE tubing ensures that materials do not adhere to its surface. This characteristic is crucial in applications where cleanliness and purity are paramount, such as in the food and pharmaceutical industries.

Electrical Insulation

PTFE is an excellent electrical insulator, making it perfect for applications in the electronics industry. Its resistance to electrical conductivity ensures safety and reliability in demanding environments.

Flexibility and Durability

Custom Teflon PTFE tubing is not only flexible but also incredibly durable. It can be bent and maneuvered without breaking, which is essential in applications requiring dynamic movement or where space is limited.

Versatility in Applications

The bespoke nature of PTFE tubing means it can be adapted for various applications across multiple industries. From automotive to medical, its versatility is unmatched.

Applications of Custom PTFE Tubing

Automotive Industry

In the automotive sector, PTFE tubing is used for fuel lines, brake lines, and hydraulic systems. Its ability to resist high temperatures and chemicals makes it an ideal choice for automotive applications.

Medical and Pharmaceutical Industries

In medical settings, PTFE tubing is used for catheters and other medical devices due to its biocompatibility and non-reactive nature. It also plays a crucial role in the pharmaceutical industry, where purity and resistance to chemicals are vital.

Chemical Processing

Chemical processing plants rely on PTFE tubing for transferring aggressive chemicals. Its chemical resistance ensures longevity and safety in environments where exposure to harsh substances is common.

Food and Beverage Industry

The food industry benefits from the non-stick and easy-to-clean properties of PTFE tubing. It’s used in processing equipment where hygiene and cleanliness are critical.

Electronics and Electrical Applications

In the electronics industry, PTFE tubing provides excellent insulation for wires and cables. Its resistance to heat and electrical conductivity make it a reliable choice for protecting sensitive electronic components.

Aerospace Industry

The aerospace sector utilizes PTFE tubing in various applications due to its lightweight and high-temperature resistance. It’s used in fuel systems, hydraulic lines, and other critical systems where reliability is essential.

Choosing the Right Teflon Tubing Manufacturer

When selecting a Teflon tubing manufacturer, it’s crucial to consider their experience, customization capabilities, and quality standards. A reputable manufacturer will offer bespoke solutions tailored to your specific needs and ensure that their products meet the highest quality standards.

Factors to Consider

- Customization Options: Ensure the manufacturer can provide custom PTFE tubing that meets your specific requirements.

- Quality Assurance: Look for manufacturers with a strong quality assurance process to ensure product reliability.

- Industry Experience: Choose a manufacturer with experience in your industry to ensure they understand the unique challenges and requirements you face.

Conclusion

Custom Teflon PTFE tubing offers numerous benefits, from chemical resistance to high-temperature tolerance and flexibility. Its wide range of applications across various industries highlights its versatility and reliability. By choosing the right manufacturer, businesses can leverage the advantages of bespoke PTFE tubing to enhance their operations and ensure long-term success.

Incorporating custom Teflon PTFE tubing into your processes can provide the efficiency, reliability, and performance needed to stay ahead in today’s competitive marketplace. Whether you’re in automotive, medical, or any other industry, PTFE tubing is a valuable asset that can help you achieve your goals.