In the demanding world of industrial machinery, where temperatures can climb to extremes, the failure of a single component can spell disaster for an entire operation. Enter high-temperature PTFE seals, a marvel of engineering that serves as a robust solution to one of industry’s most pressing challenges: maintaining integrity under heat stress. Imagine this scenario – a manufacturing plant operating at its peak, running day and night to meet production targets. Suddenly, a critical seal gives way under intense heat, halting operations and causing costly downtime. This is the nightmare that high-temperature PTFE seals are designed to prevent.

The science behind these seals is a fascinating confluence of chemistry, physics, and engineering. PTFE, or polytetrafluoroethylene, is renowned for its exceptional resistance to heat, chemicals, and wear. However, the journey to mastering its application in high-temperature environments involves understanding its unique properties and the precise engineering required to enhance its durability. In this blog post, we will delve into how these seals are designed to withstand the harshest thermal conditions and explore the innovation that makes them indispensable in industries ranging from automotive to aerospace. Join us as we unravel the secrets that keep the wheels of industry turning smoothly, despite the heat.

The Fundamentals of High-Temperature PTFE Seals

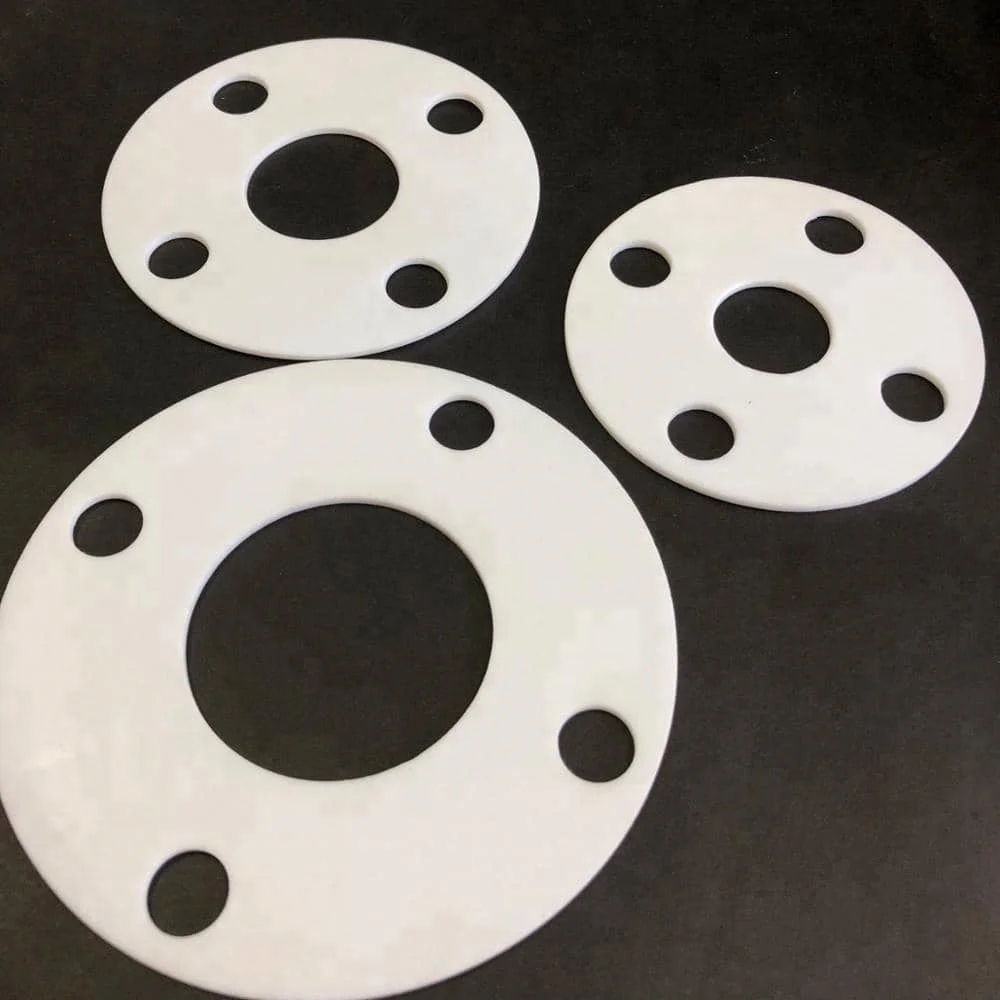

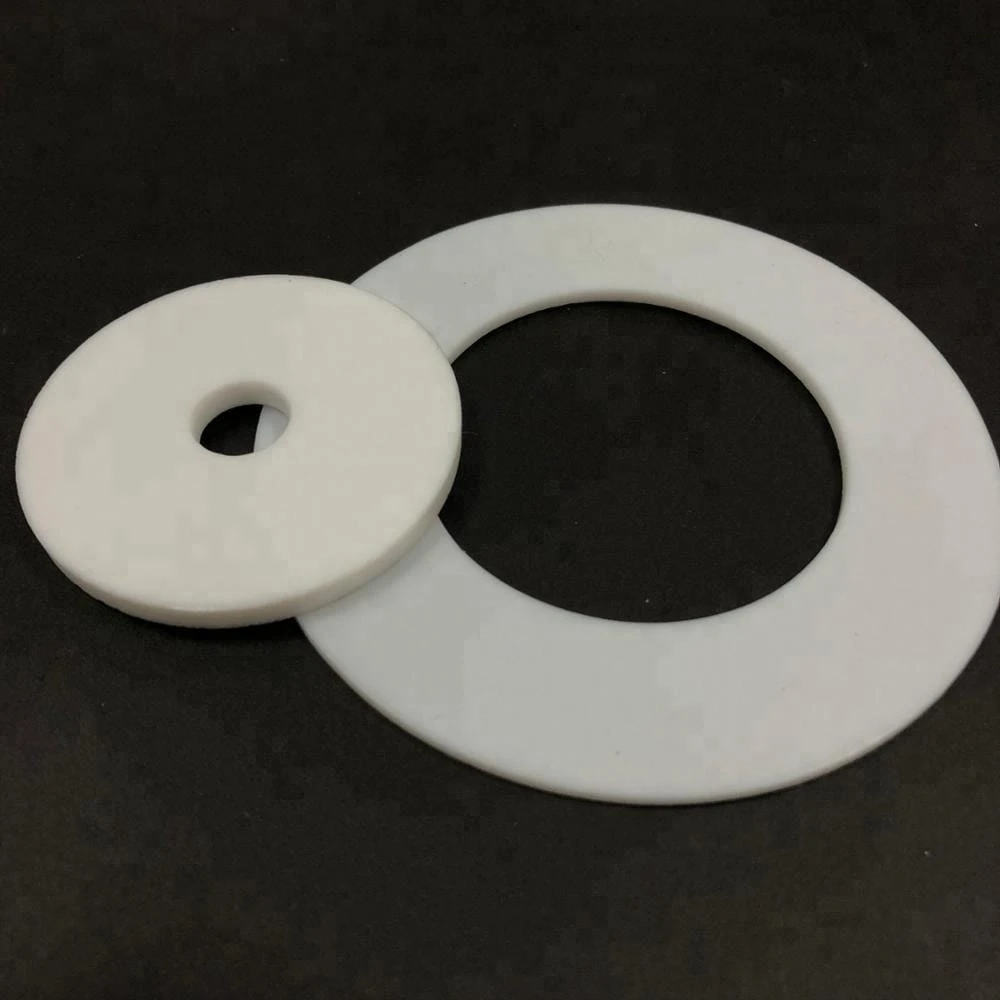

High-temperature PTFE seals are engineered to provide reliable performance under extreme thermal conditions. At their core, these seals rely on PTFE’s intrinsic characteristics—low friction, chemical inertness, and wide operating temperature range. When subjected to temperatures well above what conventional elastomeric seals can endure, PTFE maintains dimensional stability, preventing leaks that can lead to equipment failure. These seals often incorporate special fillers or reinforcements, such as glass fibers or graphite, to further bolster mechanical strength without compromising thermal resistance.

Manufacturers carefully select the grade of PTFE based on the application’s temperature, pressure, and chemical exposure. In high-pressure steam systems, for instance, seals must resist both high heat and elevated pressure cycles, necessitating more rigid filler materials. Conversely, applications with aggressive chemicals may require PTFE formulations with enhanced corrosion resistance. The design process also takes into account seal geometry, gland tolerances, and installation methods, ensuring that each high-temperature PTFE seal delivers optimal performance over extended service intervals. Proper installation and maintenance practices complete the fundamentals, safeguarding against premature wear and ensuring operational reliability.

Properties of PTFE That Make It Ideal for High Temperatures

Polytetrafluoroethylene stands out among polymers for its remarkable thermal properties. PTFE exhibits a melting point around 327°C (620°F) and retains structural integrity at temperatures exceeding 260°C (500°F) in continuous service. This wide thermal window allows high-temperature PTFE seals to function where other materials would soften or degrade. Additionally, PTFE’s very low coefficient of friction minimizes wear between moving parts, reducing heat generation at the seal interface and enhancing overall component life.

Beyond thermal stability, PTFE offers exceptional chemical inertness, resisting attack from acids, bases, solvents, and fuels. This combination of heat and chemical resistance makes PTFE the material of choice in environments where contaminants and extreme temperatures coincide. Its non-stick surface prevents buildup of deposits that could interfere with seal function, while its dielectric properties ensure electrical insulation in critical applications. Together, these characteristics underpin the widespread adoption of PTFE in demanding industrial settings.

Innovations in Enhancing Durability of PTFE Seals

Recent advances have focused on reinforcing PTFE to extend seal life under thermal cycling and mechanical stress. Composite blends incorporate fillers such as carbon, graphite, or ceramic particles to increase tensile strength, reduce creep, and improve wear resistance. These modified formulations maintain the base polymer’s heat tolerance while counteracting the tendency of pure PTFE to cold flow under pressure.

Another innovation is nano-reinforcement, where nanoparticles—like silica or alumina—disperse uniformly within the PTFE matrix. This nano-scale approach enhances load distribution, decreases friction further, and impedes crack propagation. Engineers also employ precision molding and compression techniques to achieve consistent density and minimize voids, resulting in seals that resist deformation and maintain their sealing effectiveness over thousands of hours in service. Together, these breakthroughs mark a significant leap in the durability of high-temperature PTFE seals.

Applications of High-Temperature PTFE Seals in the Automotive Industry

The automotive sector demands components that endure under bonnet temperatures often exceeding 200°C (392°F). High-temperature PTFE seals are critical in turbochargers, where exhaust heat and rotational speeds challenge traditional sealing solutions. Here, PTFE’s low friction reduces wear on shaft seals, while its thermal resilience prevents leakage of oil and gases that could impair performance or damage downstream sensors.

In electric vehicles, PTFE seals play a role in battery thermal management systems. Coolant circuits operating near power electronics require seals that withstand both hot coolant and intermittent pressure spikes. High-temperature PTFE seals ensure leak-tight performance, safeguarding battery packs from fluid intrusion and maintaining efficient heat exchange. As automotive technologies evolve toward higher efficiencies and hybrid systems, the versatility of PTFE seals continues to drive innovation in reliable, long-lasting sealing solutions.

Conclusion: Ensuring Operational Integrity with High-Temperature PTFE Seals

High-temperature PTFE seals represent a perfect marriage of material science and pragmatic engineering, delivering unmatched performance in extreme conditions. From foundational design principles to cutting-edge composite innovations, these seals mitigate risks associated with thermal stress, chemical exposure, and mechanical wear.

By leveraging the inherent advantages of PTFE and continuously refining reinforcement strategies, industries such as automotive, aerospace, and energy can count on reliable sealing solutions. Ultimately, mastering the science behind these seals is key to maintaining operational integrity, minimizing downtime, and achieving long-term cost savings in the most demanding environments.