Density: 2.1–2.3 g/cm³

Dielectric Strength: 10 kV/mm

Contraction Percentage: <0.4%

Elongation at Break: ≥150%

Water Absorption: <0.01%

Tensile Strength: ≥15.0 MPa

The PTFE Structural Component from Chunhuan is engineered for advanced sealing, insulation, and motion systems in high-demand industrial environments. Combining the exceptional chemical resistance and low-friction properties of pure or filled PTFE, this product ensures reliable operation under extreme temperatures and in highly corrosive or clean applications. Its innovative structural design offers superior strength, reduced weight, and precise compatibility with mechanical and electrical systems.

Used extensively in sealing systems, bearing bushings, valve components, and transmission assemblies, ideal for mechanical environments requiring low friction, corrosion resistance, or electrical insulation.

Available in pure PTFE or filled PTFE (with glass fiber, graphite, or carbon fiber) to improve wear resistance, rigidity, and thermal conductivity.

Exceptional Chemical Inertness: Resistant to nearly all industrial chemicals, acids, alkalis, and solvents for long-term durability.

Ultra-Low Friction Coefficient: Enables self-lubrication without oil, reducing energy loss and wear on components.

Wide Temperature Range: Maintains mechanical integrity and dimensional stability from -200°C to +260°C.

Superior Dielectric Properties: Provides outstanding electrical insulation across broad frequency and temperature ranges.

Non-Stick Surface: Prevents material buildup, allowing easy cleaning and minimizing contamination risk.

Zero Water Absorption: Ensures consistent performance even in humid or liquid environments.

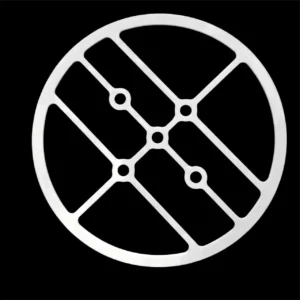

Optimized Mechanical Design: Lightweight, hollow-spoke structure supports fluid or gas flow while maintaining structural integrity.

Continuous: -200°C to +260°C

Short-term: up to 300°C

Polytetrafluoroethylene (PTFE) — pure or filled with glass fiber, graphite, or carbon.

Typically 0.1–10 MPa (1–100 bar), depending on design and filler composition.

Integrated Circular Profile: Ensures balanced stress distribution and easy alignment during installation.

Radial-Spoke Layout: Provides high structural rigidity while reducing overall weight.

Functional Apertures: Precisely machined holes allow for mounting, alignment, ventilation, and pressure balancing.

Custom CNC Machining: Each part is precision-crafted with tight tolerances to meet exact operational requirements.

Chemical & Process Industry: Sealing rings, valve seats, reactor gaskets, and distributor plates.

Semiconductor & Electronics: Insulation carriers, wafer holders, and ultra-pure system components.

Food & Pharmaceutical: Bearing bushings, release plates, and paddles compliant with FDA and USP Class VI standards.

Automotive & Aerospace: Transmission seals, fuel system liners, and cryogenic valve parts.

Machinery & Industrial Equipment: Low-friction bearings, dry-run slides, electrical insulators, and vacuum mountings.

The PTFE Structural Component by Chunhuan represents a fusion of chemical resistance, precision engineering, and mechanical innovation. Its lightweight yet durable design ensures performance stability under extreme conditions while preventing contamination and minimizing maintenance costs. From high-purity environments to harsh industrial systems, this product delivers the efficiency, safety, and longevity that modern industries demand.