Industrial settings often demand materials that can withstand extreme conditions, and rigid PTFE tubing is one of the top choices for many applications. Known for its durability and versatility, PTFE (Polytetrafluoroethylene), often referred to by its brand name Teflon, offers numerous benefits across various industries.

In this article, we will explore the advantages of rigid PTFE tubing, its applications, and why it stands out in industrial uses.

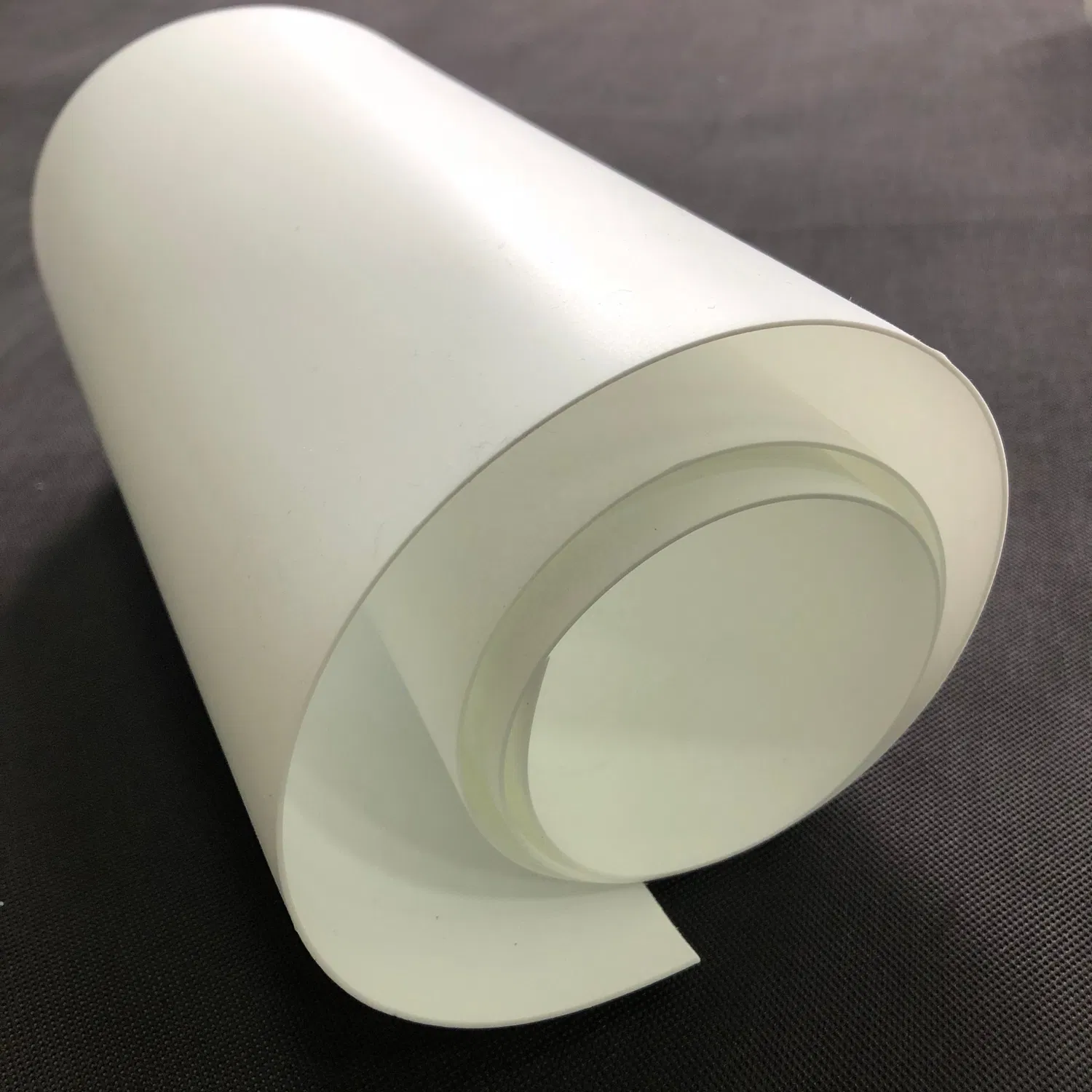

PTFE tubing is a type of plastic pipe made from the polymer PTFE. It is renowned for its unique properties, including high temperature resistance, chemical inertness, and non-stick nature. This makes it suitable for a wide range of applications, particularly in harsh environments.

Properties of PTFE

PTFE is characterized by its ability to withstand high temperatures, with a melting point around 327°C (620°F). Its chemical resistance is unparalleled, making it resistant to nearly all chemicals, including acids and bases. Additionally, it has a low coefficient of friction, meaning that substances do not easily stick to its surface.

Advantages of Using Rigid PTFE Tubing

Rigid PTFE tubing offers a host of advantages, particularly in industrial settings where reliability and performance are critical.

High-Temperature Resistance

One of the most significant benefits of rigid PTFE tubing is its ability to withstand high temperatures. High-temperature PTFE tubing can operate effectively in a range of extreme conditions, maintaining its structural integrity and performance.

This makes it an ideal choice for industries that require materials to perform under intense heat, such as chemical processing, automotive, and aerospace.

Chemical Inertness

PTFE tubing is chemically inert, which means it does not react with other substances. This property is crucial for industries that handle aggressive chemicals. Rigid PTFE tubing remains stable and does not degrade when exposed to acids, bases, and solvents.

Non-Stick Surface

The non-stick nature of PTFE ensures that materials passing through the tubing do not adhere to its walls. This is particularly beneficial in applications involving sticky or viscous substances, as it minimizes the risk of clogging and facilitates easy cleaning.

Electrical Insulation

PTFE also serves as an excellent electrical insulator, making it suitable for applications in the electrical and electronics industries. It prevents electrical interference and maintains signal integrity, which is critical in high-performance electronic devices.

Longevity and Durability

Rigid PTFE tubing is known for its durability, capable of withstanding harsh conditions over extended periods. Its robust nature reduces the need for frequent replacements, leading to cost savings in the long run.

Applications of Rigid PTFE Tubing in Industries

Due to its unique properties, rigid PTFE tubing is used across a wide range of industries.

Chemical Processing

In the chemical industry, PTFE tubing is used for transporting corrosive chemicals without the risk of reaction or contamination. Its chemical resistance and high-temperature tolerance make it ideal for handling aggressive substances safely.

Automotive Industry

In the automotive sector, PTFE hoses are used in fuel lines, brake systems, and emissions controls. The material’s ability to withstand high temperatures and harsh chemicals ensures reliability and safety in vehicle operations.

Aerospace Industry

The aerospace industry relies on PTFE tubing for hydraulic systems, fuel lines, and cable insulation. Its lightweight nature, combined with its high-performance characteristics, makes it a preferred choice in aviation and space applications.

Food and Beverage

PTFE’s non-toxic and non-stick properties make it ideal for use in the food and beverage industry. It is used in applications that require hygienic, easy-to-clean surfaces, such as in fluid transfer lines and food processing equipment.

Electronics and Electrical

PTFE’s excellent dielectric properties make it an ideal material for insulating electrical wires and components. It is used in high-frequency cables and connectors to ensure reliable performance in electronic devices.

Why Choose Rigid PTFE Tubing?

When selecting materials for industrial applications, several factors make rigid PTFE tubing an attractive option.

Versatility and Adaptability

Rigid PTFE tubing can be manufactured in various sizes and thicknesses to meet specific industrial requirements. Its adaptability allows it to be used in a myriad of applications, from small-scale operations to large industrial systems.

Cost-Effectiveness

While the initial cost of PTFE tubing may be higher than some alternatives, its longevity and low maintenance requirements offer a cost-effective solution over time. The reduced need for replacements and repairs translates into significant savings for industries.

Environmental Resistance

PTFE tubing can withstand extreme environmental conditions, including UV exposure and weathering. This makes it suitable for outdoor applications where materials are subject to environmental stressors.

Conclusion

Rigid PTFE tubing stands out as a superior choice for industrial applications due to its high-temperature resistance, chemical inertness, non-stick properties, and durability. Its versatility and adaptability make it a valuable asset across various industries, from chemical processing to aerospace.

Choosing PTFE tubing ensures reliability, safety, and cost-effectiveness, making it an indispensable component in industrial operations. Whether you are looking to enhance performance or ensure safety in your processes, rigid PTFE tubing offers a robust solution that meets the demands of modern industry.

By understanding the advantages and applications of rigid PTFE tubing, industries can make informed decisions that optimize their operations and extend the lifespan of their systems. Embrace the benefits of PTFE and elevate your industrial processes to new heights.