Imagine a world where components in machinery or appliances could endure extreme temperatures and pressures without losing their integrity. A world where maintenance costs dwindle because parts resist wear and tear longer than ever before. Welcome to the transformative power of PTFE gaskets, a seemingly simple yet incredibly sophisticated solution that has redefined durability across countless industries. These remarkable gaskets are engineered from polytetrafluoroethylene—known more commonly by its trade name, Teflon—and have earned their rightful place as the ultimate non-stick solution in modern engineering.

If you’ve ever marveled at how a frying pan can keep eggs from adhering to its surface while cooking, you already possess a glimpse into the magic of PTFE. But beyond your kitchen, this material performs wonders in environments as varied as chemical processing plants and the aerospace industry. PTFE gaskets offer an unparalleled advantage: they seal essentials with precision while providing unmatched resilience against corrosion, chemicals, and heat. By delving deeper into the world of PTFE gaskets, you’ll uncover why these underappreciated heroes are critical to both innovation and efficiency in today’s technologically-driven landscape.

The Science Behind PTFE Gaskets

At its core, the science behind PTFE gaskets lies in the unique molecular structure of polytetrafluoroethylene. Each polymer chain in PTFE is composed of carbon atoms fully shielded by fluorine atoms, creating an extraordinarily stable and inert material. This fluorine-carbon bond is one of the strongest in organic chemistry, which explains why ptfe gaskets resist degradation when exposed to aggressive chemicals, extreme pH levels, and high temperatures. Unlike rubber or silicone, PTFE’s chemical inertness means it will not swell, shrink, or weaken over time in hostile environments.

Beyond chemical resistance, the non-stick surface of ptfe gaskets originates from their low coefficient of friction. The fluorine atoms create a slick exterior that prevents other substances from adhering, making the gaskets self-lubricating. This property is especially advantageous in dynamic applications where repeated assembly and disassembly occur. Additionally, PTFE maintains flexibility down to cryogenic temperatures, ensuring a reliable seal even in subzero conditions. When heat climbs above 200 °C, PTFE gaskets remain dimensionally stable and maintain sealing integrity up to approximately 260 °C, then return to form without cold flow once cooled.

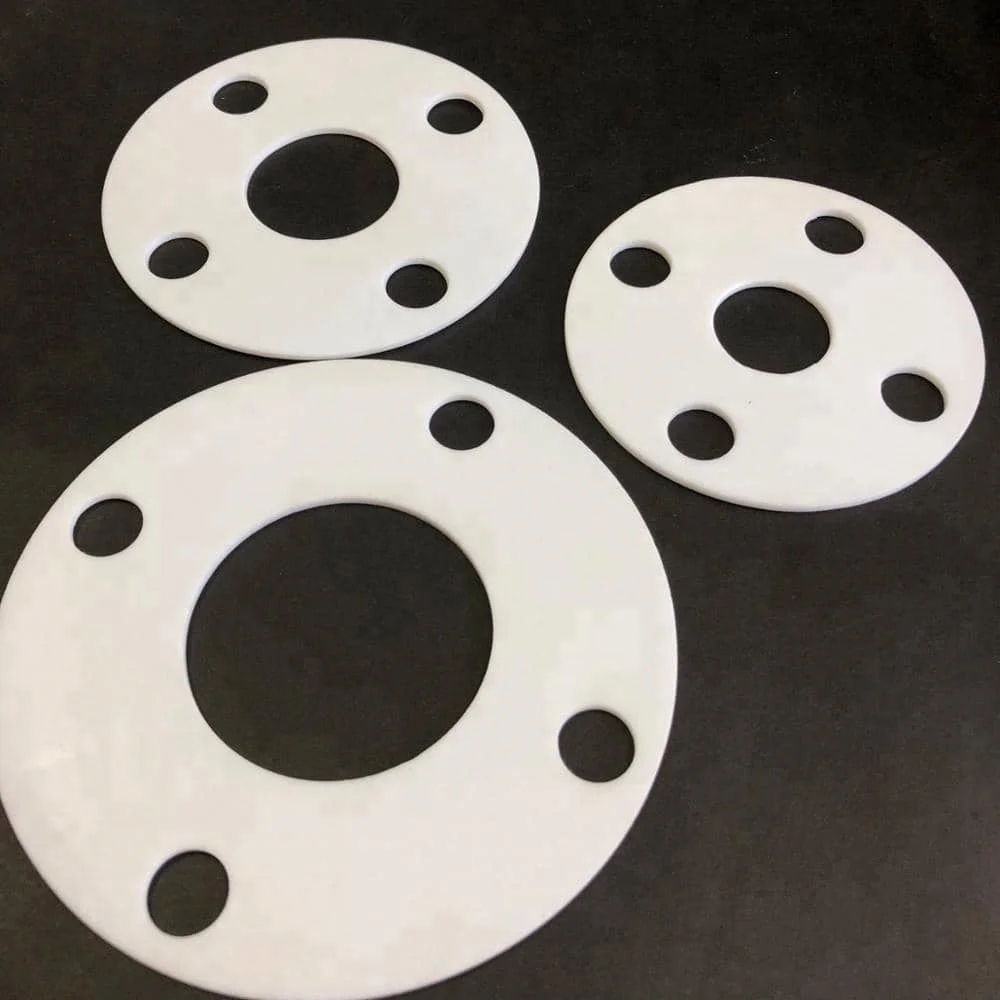

Applications of PTFE Gaskets in Machinery

PTFE gaskets find widespread use in industries that demand reliable sealing under extreme conditions. In the chemical processing sector, these gaskets stand up to corrosive acids, alkalis, and solvents found in pipelines, reactors, and storage tanks. Their inertness guarantees minimal contamination, making PTFE the go-to choice for food processing and pharmaceutical equipment where purity is paramount.

In the aerospace and automotive industries, ptfe gaskets serve in fuel systems, hydraulic lines, and turbochargers, where high pressures and temperatures are the norms. Their stability under cycling thermal loads reduces the risk of leaks and mechanical failure, extending maintenance intervals and enhancing safety. Similarly, in the oil and gas sector, PTFE seals and gaskets accommodate the rugged demands of drilling and refining operations, managing pressures that exceed several thousand psi while resisting hydrogen sulfide and other corrosive agents.

Advantages of Using PTFE Gaskets

One of the primary advantages of ptfe gaskets is their exceptional chemical compatibility. They can withstand virtually all industrial fluids, including aggressive acids, solvents, and oxidizing agents that would quickly degrade most elastomers. This broad compatibility not only prolongs service life but also reduces the need for frequent gasket changes and the associated downtime.

Thermal performance is another standout feature. With an operating temperature range from –200 °C to +260 °C, PTFE gaskets deliver reliable sealing across cryogenic, ambient, and high-temperature applications. Their low permeability to gases and liquids ensures that pressurized systems remain leak-tight, improving safety and efficiency. The non-stick nature of PTFE also prevents material build-up on sealing surfaces, simplifying maintenance and eliminating the need for additional lubricants or release agents.

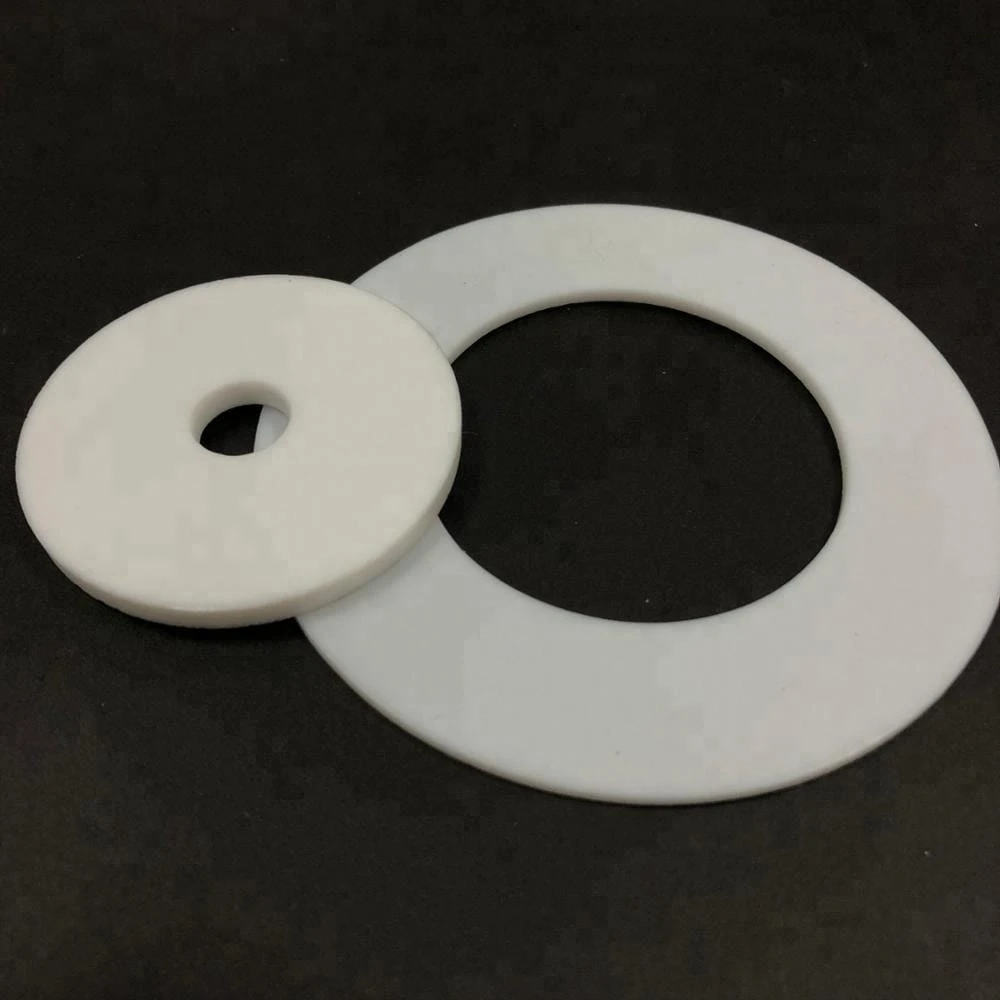

Comparing PTFE Gaskets with Other Sealing Solutions

When stacked against traditional elastomeric gaskets such as NBR, EPDM, or silicone, ptfe gaskets outshine many alternatives in chemical resistance and temperature tolerance. Elastomers typically degrade when exposed to aggressive chemicals or heat above 150 °C, whereas PTFE maintains structural integrity well beyond 200 °C. This broad operating window makes PTFE the preferred choice for processes featuring wide temperature fluctuations.

However, PTFE’s hardness and creep characteristics differ from softer seal materials. Under very high static loads, PTFE gaskets can exhibit cold flow, potentially requiring backup rings or higher flange loads to maintain a tight seal. Despite this, the life-cycle cost of ptfe gaskets often remains lower due to their long service intervals, reduced replacement frequency, and minimal risk of chemical attack. In applications where metal-reinforced or filled PTFE variants are used, sealing performance can match or exceed that of high-performance elastomers and composite gaskets.

Conclusion: Embracing the Future with PTFE Gaskets

PTFE gaskets have revolutionized sealing technology by combining unrivaled chemical resistance, wide temperature tolerance, and self-lubricating properties. Their unique molecular structure ensures long-lasting performance in the most demanding environments, from chemical plants to aerospace systems.

As industries continue to push the boundaries of process conditions and efficiency requirements, ptfe gaskets will remain a cornerstone of reliable and cost-effective sealing solutions. Embracing these clever components means investing in fewer shutdowns, safer operations, and greater innovation for the challenges ahead.