In the realm of modern industry, PTFE lined pipes are nothing short of revolutionary. These marvels of engineering have made significant contributions to sectors ranging from chemical processing to pharmaceuticals, where corrosion resistance and durability are paramount. Yet, how much do we truly understand about the PTFE lined pipe manufacturing process that produces these indispensable components? Delving into this process is like lifting the curtain on a carefully choreographed performance where precision, science, and art beautifully intersect.

Imagine a world where your infrastructure could withstand the harshest chemicals, extreme temperatures, and relentless usage without corrosion. This isn’t a distant dream, but rather an everyday reality enabled by PTFE lined pipes. These pipes owe their strength and resilience to a meticulous manufacturing process that transforms raw materials into high-performance solutions. In this blog post, we’ll navigate the intricate steps involved, revealing the thoughtful engineering and innovation that underpin every PTFE lined pipe. Prepare to embark on a journey that demystifies the complexities and showcases the brilliance behind a cornerstone of industrial advancement.

Understanding the Importance of PTFE Lined Pipes

PTFE lined pipes represent a crucial innovation in industrial fluid handling systems. Their unique combination of a robust metal substrate with an inner lining of polytetrafluoroethylene provides unmatched chemical resistance and mechanical strength. Industries from petrochemicals to pharmaceuticals rely heavily on these components to transport aggressive acids, alkalis, solvents, and other corrosive media safely. By preventing direct contact between the conveyed fluid and the metal pipe wall, PTFE liners dramatically reduce maintenance costs, downtime, and the risk of catastrophic leaks.

Furthermore, PTFE’s non-stick characteristics minimize build-up and fouling inside pipes, ensuring consistent flow rates and simplifying cleaning procedures. This property is especially valuable in sectors where product purity is non-negotiable, such as food processing and biotechnology. Additionally, PTFE lined pipes excel under extreme temperature variations, maintaining integrity from cryogenic applications up to temperatures exceeding 260°C. As global industries push toward higher efficiency and stringent safety standards, understanding why PTFE lined pipes are indispensable underscores the value of mastering the ptfe lined pipe manufacturing process.

Overview of Raw Materials Used in PTFE Lined Pipe Manufacturing

The foundation of every PTFE lined pipe lies in selecting the right raw materials for both the metal pipe and the PTFE resin. Typically, carbon steel, stainless steel, or alloy substrates form the pipe’s structural core. These metals provide the necessary strength and pressure ratings required in demanding applications. Stainless steel, with its inherent corrosion resistance, is favored for many installations, while carbon steel offers cost benefits where internal chemical exposure is moderate.

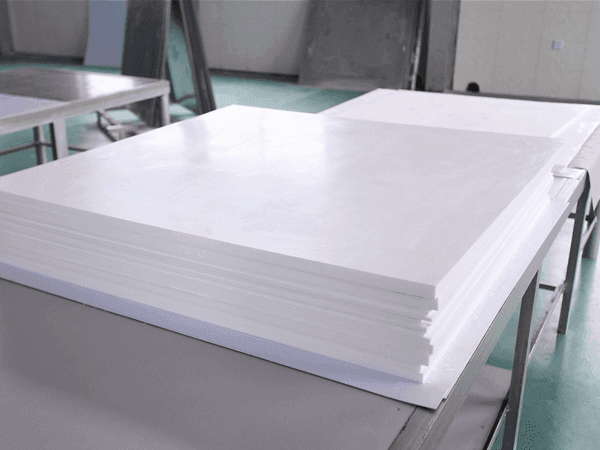

Equally important is the quality of the PTFE resin used for the lining. Manufacturers procure high-purity, virgin PTFE powders with consistent particle size distribution to ensure even flow and compaction during the lining stage. Additives and stabilizers may be introduced to tailor properties like creep resistance and adhesion strength. The resin’s melt flow index and tensile strength parameters are closely monitored to guarantee the final liner adheres uniformly to the pipe’s inner surface, forming an impermeable, seamless barrier against corrosive agents.

Bonding the PTFE Liner to the Pipe

After preparing the metal substrate and PTFE resin, the next critical step is bonding the PTFE liner inside the pipe. This phase entails complete surface preparation of the pipe’s interior—often involving abrasive blasting and chemical cleaning—to remove any mill scale or contaminants. Proper surface roughness and cleanliness ensure optimal mechanical interlocking and chemical adhesion between the PTFE and the metal base.

The bonding process typically utilizes a specialized glue or adhesive system formulated to withstand the subsequent sintering temperatures. Once the adhesive is applied, the PTFE powder is introduced and compacted onto the pipe wall, forming an initial lining layer. These steps demand exacting control over temperature, pressure, and timing to prevent delamination and ensure the lining’s uniform thickness throughout the pipeline.

Quality Control Measures in PTFE Lined Pipe Production

Quality assurance is integral to the ptfe lined pipe manufacturing process. From incoming inspection of raw materials to final product verification, stringent protocols safeguard performance and compliance. Non-destructive testing (NDT) methods, such as ultrasonic thickness measurement and hydrostatic pressure testing, confirm both the metal substrate integrity and the PTFE liner’s impermeability.

Additionally, manufacturers conduct periodic peel adhesion tests to quantify the bond strength between the liner and pipe wall. Visual inspections under UV light may reveal pinholes or voids invisible to the naked eye. Temperature cycling and chemical immersion tests further simulate real-world operating conditions, ensuring the finished pipe sustains structural and chemical resilience. Through meticulous documentation and traceability, every production batch meets industry standards and customer specifications before shipment.

Conclusion: The Future of PTFE Lined Pipe Manufacturing

As global industries evolve, the demand for advanced fluid handling solutions continues to grow. Innovations in PTFE composites, automated lining systems, and real-time quality monitoring promise to enhance efficiency and reduce costs in the ptfe lined pipe manufacturing process.

By embracing these technological advancements, manufacturers will deliver even more reliable, high-performance piping systems. Ultimately, PTFE lined pipes will remain at the forefront of industrial safety and sustainability, reinforcing their vital role in modern infrastructure.