In the intricate world of industrial engineering, where precision and resilience are not mere preferences but necessities, the PTFE lined pipe emerges as a true marvel of innovation. With its remarkable ability to withstand the harshest of chemicals and extreme temperatures, this engineering masterpiece is a linchpin in industries ranging from chemical manufacturing to food processing. But what exactly makes these pipes essential? The answer lies in the nuanced ptfe lined pipe specification—a blueprint that ensures reliability and safety in demanding environments.

Imagine a scenario where the tiniest flaw in a pipeline could lead to catastrophic outcomes. The stakes are high when transporting corrosive materials; hence, understanding the intricate specifications of PTFE lined pipes is not just beneficial but crucial. This blog post delves into the detailed specifications that define these durable pipelines, uncovering the meticulous engineering that guarantees their resistance and longevity. Whether you’re an industry professional or an enthusiast keen on discovering the intersection of science and practicality, this exploration promises to enlighten and intrigue.

The Importance of PTFE Lined Pipes in Industrial Engineering

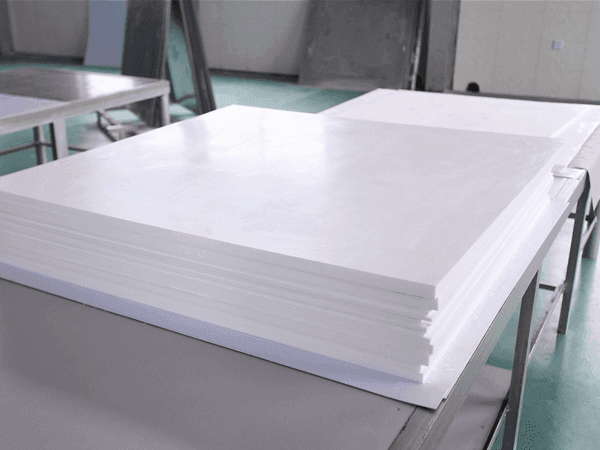

In modern industrial systems, the integrity of fluid conveyance is paramount—any compromise can lead to safety hazards, costly downtime, or product contamination. PTFE lined pipe specification addresses these concerns by combining a robust metal shell, often carbon steel or stainless steel, with an inner lining of polytetrafluoroethylene (PTFE). This fusion offers the best of both worlds: structural strength from the metal and exceptional chemical resistance from the PTFE layer. Such a dual-structured design is indispensable wherever aggressive chemicals, slurries, or abrasive media must be transported under pressure.

Beyond chemical compatibility, PTFE lined pipes excel in maintaining purity, making them the go-to choice in pharmaceutical, biotechnology, and food processing plants. The inert nature of PTFE prevents leaching of contaminants, ensuring product quality and regulatory compliance. Moreover, the lining minimizes adhesion and fouling, reducing maintenance intervals and cleaning costs. By adhering strictly to the ptfe lined pipe specification—covering aspects like lining thickness, adhesion methods, and flange seals—engineers guarantee longevity and performance under the harshest industrial conditions.

Taking a holistic view, the importance of PTFE lined pipes transcends individual parameters; they epitomize reliability. Their predictable behavior under mechanical stress, combined with chemical inertness, translates to safer operations and lower life-cycle costs. For industries where even minor leaks or contamination can have severe repercussions, adherence to detailed ptfe lined pipe specifications is not optional but fundamental. This engineered perfection empowers facilities to run confidently, knowing their pipelines meet exacting standards.

Key Specifications for Chemical Resistance

At the core of PTFE lined pipe design is the lining’s ability to resist chemical attack. The primary ptfe lined pipe specification here involves the thickness of the PTFE layer, typically ranging from 1.5 mm to 6 mm, depending on service conditions. A thicker lining offers enhanced resistance to aggressive acids, alkalis, and solvents, but must be balanced against pressure drop considerations.

Equally critical is the method of bonding the PTFE to the pipe’s inner wall. Adhesion techniques—such as thermal expansion bonding or special mechanical anchoring—ensure the lining remains intact under fluctuating pressures and temperatures. Strict adherence to these specifications prevents delamination, thus preserving pipeline integrity and safeguarding downstream equipment.

Temperature Tolerance: A Critical Specification

PTFE lined pipes boast an impressive operating range, typically from -200°C to +260°C. This broad spectrum makes them versatile for both cryogenic applications and high-temperature processes. However, the exact ptfe lined pipe specification must consider the combined effects of temperature, pressure, and chemical media to prevent premature failure.

In practice, engineers refer to temperature rating charts provided by manufacturers and industry standards (e.g., ASTM, ISO). These charts detail the allowable working pressures at various temperatures, ensuring that the pipeline operates safely within its design envelope. By following these critical specifications, facilities can confidently deploy PTFE lined systems in extreme environments without risking structural compromise or safety violations.

Size and Dimension Considerations

Selecting the correct pipe size involves more than matching inlet and outlet diameters. The ptfe lined pipe specification for dimensions covers outside diameter (OD), wall thickness, and lining tolerance. Standard sizes range from DN15 (½”) to DN400 (16″) for PTFE lined systems, but custom dimensions are often available for specialized projects.

An important factor is the minimum lining thickness, which must be maintained uniformly throughout the pipe run. Variations can lead to thin spots that become failure points under abrasion or chemical attack. Additionally, flange dimensions, bolt patterns, and face-to-face lengths must adhere to industry norms like ASME B16.5 or EN 1092-1. By rigorously following these specifications, engineers ensure compatibility with existing systems and simplify installation.

Applications Across Various Industries

Он chemical processing industry is perhaps the most demanding environment for pipeline materials. PTFE lined pipes handle corrosive acids, solvents, and slurries with ease, minimizing downtime due to corrosion-related leaks. Whether in sulfuric acid concentration or chlor-alkali production, adherence to ptfe lined pipe specification ensures uninterrupted, safe operations.

In the pharmaceutical and biotechnology sectors, PTFE lined pipelines maintain sterility and chemical purity. Their non-stick surface prevents residue build-up, facilitating quick changeovers between batches. Similarly, in food and beverage processing, the inert PTFE lining meets stringent hygiene standards, preventing flavor carryover and contamination.

Other notable applications include water treatment, where PTFE lined pipes transport treated effluents and harsh cleaning chemicals, and semiconductor manufacturing, where ultra-pure chemicals demand absolute contamination control. Even in aerospace and defense, these pipelines convey rocket propellants and high-purity gases. Across all these sectors, the ptfe lined pipe specification is the blueprint that guarantees performance under the most exacting conditions.

Conclusion: The Future of PTFE Lined Pipe Technology

As industries evolve toward greener processes and more stringent safety standards, PTFE lined pipes remain at the forefront of fluid handling innovation. Advances in lining techniques, enhanced adhesion methods, and real-time monitoring are set to refine ptfe lined pipe specification even further.

Ultimately, the future of PTFE lined pipe technology lies in continuous improvement—meeting emerging challenges with engineered perfection. By understanding and applying the detailed specifications outlined here, engineers can ensure pipelines that are not only fit for today’s demands but ready for tomorrow’s breakthroughs.