In the bustling world of modern industry, efficiency, durability, and reliability are paramount. Companies are constantly on the hunt for materials that not only withstand the demanding nature of industrial applications but also enhance performance. Enter the silicone gasket—a seemingly simple yet incredibly versatile component that has revolutionized how various sectors operate. From automotive to aerospace, these unsung heroes play a critical role in ensuring machinery functions smoothly under pressure, offering a robust solution to many age-old industrial challenges.

Imagine a material that can endure extreme temperatures, resist degradation from chemicals, and provide an airtight seal in the most demanding environments. Silicone gaskets offer all this and more, becoming an indispensable part of cutting-edge technology. Many industries have seen significant cost and time savings by integrating silicone gaskets into their operations. By understanding and utilizing this resilient material, companies are unlocking unprecedented efficiencies, paving the way for innovation and growth across multiple sectors. Whether you’re an engineer searching for reliable solutions or a business owner aiming to upgrade operations, discovering the benefits of silicone gaskets could redefine your approach to industrial needs.

The Versatility of Silicone Gaskets in Modern Industry

The versatility of silicone gaskets is rooted in their unique combination of physical and chemical properties. Unlike traditional sealing materials, a silicone gasket can withstand a broad temperature range—from cryogenic lows of -60°C to extreme highs exceeding 200°C—without losing elasticity or structural integrity. This remarkable thermal stability ensures reliable sealing performance in environments where metal, rubber, or other polymers might fail. Furthermore, silicone’s inherent resistance to ozone, UV radiation, and various chemicals means affected surfaces remain protected even under corrosive or harsh exposure. This resilience makes silicone gaskets an ideal choice for applications demanding consistent performance, especially where long-lasting seals are critical to safety and efficiency.

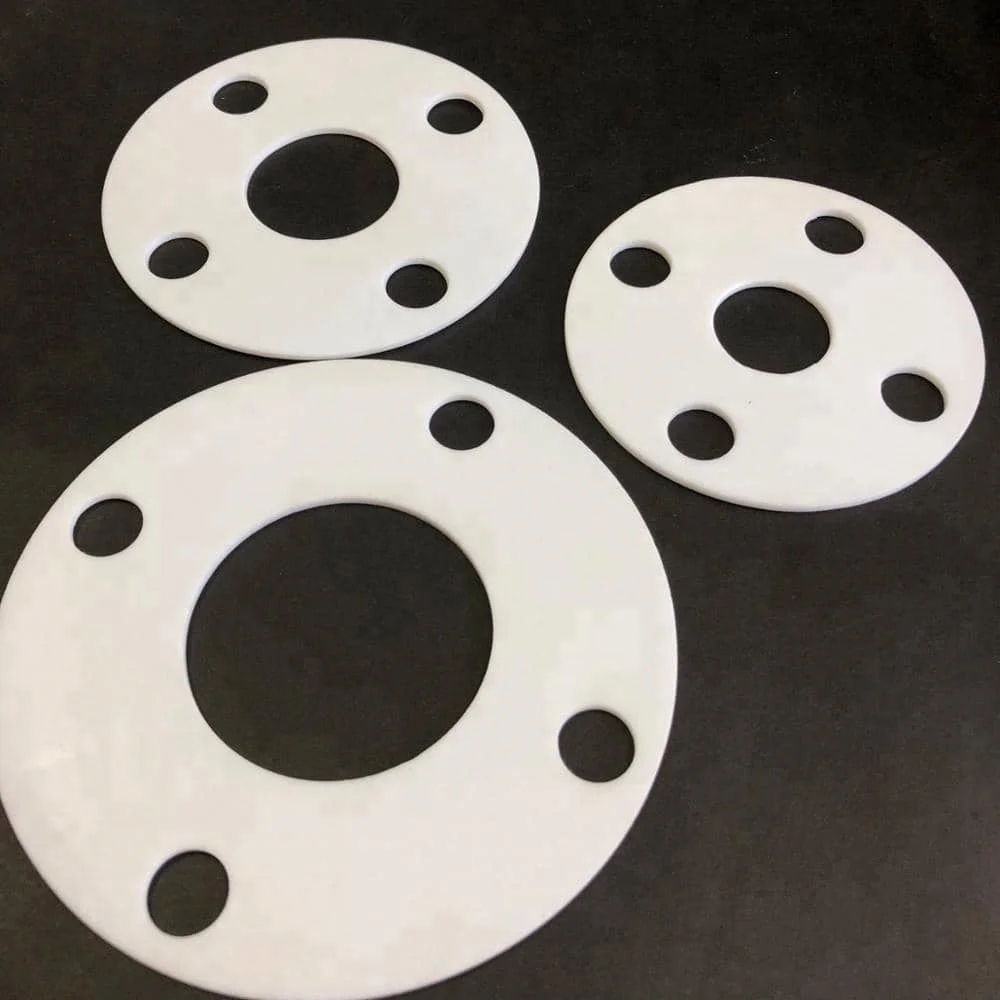

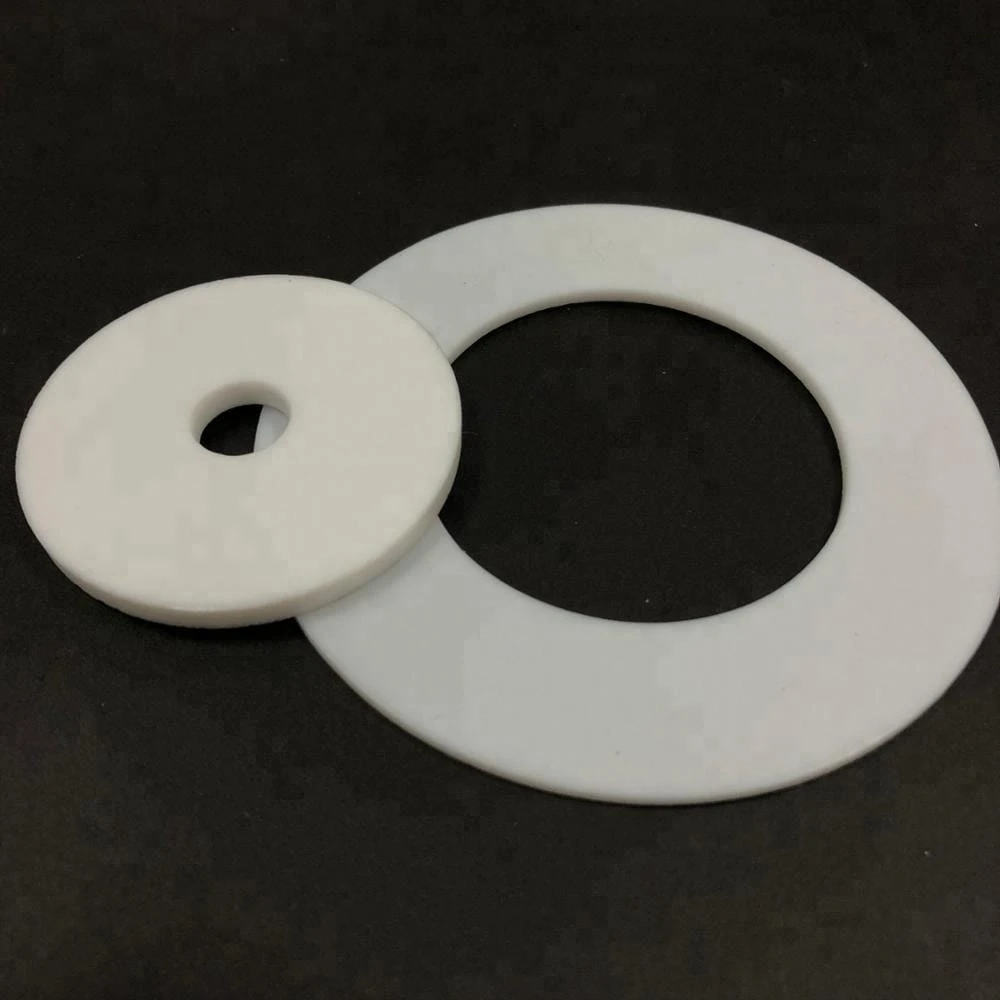

Beyond their exceptional durability, silicone gaskets offer unparalleled design flexibility, allowing engineers to create custom profiles that perfectly meet unique sealing requirements. Whether molded as flat sheet gaskets, extruded O-rings, or complex multi-lip seals, silicone gaskets can be produced in various durometers, colours, and formulations to suit industry-specific needs. This adaptability extends to sectors like electronics, where precise environmental seals protect sensitive circuitry, or in the food and pharmaceutical industries, where silicone gaskets are trusted for their FDA-approved, non-toxic formulations. As the backbone of reliable sealing solutions, silicone gaskets continue to redefine industry expectations, proving that one small component can have a profound impact on performance and longevity across countless applications.

Understanding the Manufacturing Process of Silicone Gaskets

The manufacturing process of a silicone gasket begins with high-purity silicone rubber compounds tailored to meet precise performance criteria. At the heart of every gasket lies a silicone polymer base, which is compounded with reinforcing fillers, curing agents, and additives. Fillers like silica enhance mechanical strength and thermal stability, while curing agents catalyze cross-linking reactions that transform the silicone from a pliable paste into a durable elastomer. During compounding, precise measurements of each component are fed into internal mixers or kneader equipment, ensuring a uniform blend that will consistently deliver the desired durometer, tensile strength, and compression set resistance. Colorants and other specialty additives can also be incorporated at this stage to meet aesthetic or functional requirements—for example, conductive fillers for electromagnetic shielding or flame-retardant additives for high-safety environments.

Once the silicone compound is thoroughly mixed, it moves to the molding and curing phase. Depending on the complexity and volume of the required silicone gasket, manufacturers may choose from injection, compression, or transfer molding techniques. In compression molding, for instance, pre-weighed silicone blanks are placed into a heated mold cavity, where precise pressure and temperature cause the material to flow and fill intricate profiles. Injection molding, on the other hand, uses high-pressure injection machines to force the silicone compound into closed molds, enabling faster cycle times and tighter dimensional tolerances for high-volume production. After molding, the gaskets undergo a post-curing process—typically in an oven at controlled temperatures—to ensure complete cross-linking and to drive off any residual volatiles. Finally, rigorous inspection and testing—including dimensional checks, hardness tests, and leak-rate evaluations—verify that each silicone gasket meets industry standards before being prepared for shipment.

Benefits of Silicone Gaskets in Automotive Engineering

Within automotive engineering, the implementation of silicone gaskets has transformed how vehicles maintain reliability, safety, and efficiency under grueling operating conditions. Engine components such as cylinder heads, valve covers, and oil pans demand gaskets that can endure significant thermal cycling, exposure to engine oils, coolants, and fuels. Silicone gaskets excel in these high-stress environments due to their ability to seal tight under compression while retaining elasticity through fluctuating temperatures. They also resist automotive fluids and chemicals, ensuring that leaks are minimized and that service intervals can be extended. Manufacturers often select silicone gaskets over conventional options when precision sealing against high pressures and extreme temperature variations is paramount—an essential consideration for modern internal combustion engines and hybrid powertrains alike.

Beyond engine compartments, silicone gaskets contribute to noise, vibration, and harshness (NVH) reduction, helping vehicles deliver a smoother, quieter ride. The material’s inherent damping properties help absorb vibrations from the drivetrain and chassis, mitigating rattles and structural resonance. In climate-control systems, silicone gaskets ensure airtight seals around HVAC housings, improving airflow efficiency and passenger comfort. Additionally, the lightweight nature of silicone elastomers supports ongoing automotive efforts to reduce vehicle weight for enhanced fuel economy and electric vehicle range. With their long service life and low maintenance requirements, silicone gaskets offer tangible cost savings for both manufacturers and vehicle owners, making them a cornerstone of modern automotive design and engineering.

Environmental Impact: Sustainability of Silicone Gaskets in Industry

As industries heed mounting environmental concerns, the sustainability credentials of silicone gaskets have become a focal point of discussion. Unlike many organic elastomers that degrade rapidly under heat, ozone, or UV exposure, silicone gaskets maintain their physical and chemical properties over extended service periods. This remarkable durability not only reduces the frequency of replacements—thereby cutting down on material waste—but also reduces the downtime and energy consumption associated with maintenance activities. Additionally, silicone’s inertness and resistance to microbial growth make these gaskets suitable for sterile or sanitary applications, further aligning with strict environmental and safety regulations in sectors like food processing and pharmaceuticals.

From a life-cycle perspective, advances in silicone manufacturing and recycling are enhancing the eco-friendliness of silicone gaskets. While silicone itself is not biodegradable, research into reclaiming and reprocessing silicone scrap is gaining traction, allowing manufacturers to recover and convert waste materials back into usable compounds. Some producers now offer closed-loop recycling programs, collecting used or off-cut silicone gaskets for regrinding and reincorporation into new batches of silicone compounding. Furthermore, the energy efficiency gains achieved through superior sealing performance—such as reduced leak rates in HVAC systems and chemical processing plants—translate into lower carbon footprints during operational phases. By prioritizing recycling initiatives and optimizing production processes, the industry is steadily reducing the overall environmental impact associated with silicone gaskets.

Embracing Innovation: Future Trends and Developments in Silicone Gasket Technology

Innovation in silicone gasket technology is evolving rapidly as manufacturers and researchers explore new materials, processes, and functional capabilities. One major trend is the integration of nanocomposite fillers—such as graphene or silicon carbide—to enhance mechanical strength, thermal conductivity, and electrical properties. By dispersing nanoscale particles within silicone matrices, engineers can create gaskets that offer superior performance under extreme stress and are equipped for applications requiring electromagnetic shielding or rapid heat dissipation. Similarly, advances in additive manufacturing are making it possible to 3D print custom silicone gaskets with intricate geometries, reducing tooling costs and enabling fast prototyping for low-volume specialized applications. These breakthroughs not only accelerate product development cycles but also allow greater design freedom to optimize seal performance in complex assemblies.

Looking ahead, the convergence of smart technologies with silicone gaskets is set to redefine sealing solutions. Embedding sensors directly into gasket structures could provide real-time monitoring of pressure, temperature, or chemical exposure, alerting maintenance teams to potential leaks before they escalate. Shape-memory silicones and self-healing formulations are also under development, promising gaskets that recover their original shape after deformation or repair minor damage autonomously, thereby extending service life and reducing unplanned downtime. Sustainable innovations—such as the use of bio-based silicone precursors—are likewise gaining traction, mirroring broader industry shifts toward greener products. As these technologies mature, silicone gaskets will continue to push the boundaries of what’s possible, delivering smarter, more resilient, and environmentally responsible sealing solutions for modern industry needs.

Заключение

In summary, the silicone gasket stands out as a critical enabler of reliability, efficiency, and innovation across modern industries. Its exceptional thermal stability, chemical resistance, and design adaptability make it indispensable for sectors ranging from automotive and aerospace to food processing and electronics.

As sustainability efforts and smart technology integration accelerate, silicone gaskets are poised to become even more versatile—offering longer service life, enhanced monitoring capabilities, and reduced environmental impact. Embracing this advanced sealing solution will empower organizations to optimize performance, minimize downtime, and pave the way for future industrial breakthroughs.