In the world of 3D printing, achieving optimal performance requires precise setup and maintenance of your printer components. One key element in this setup is the PTFE (Polytetrafluoroethylene) tube. This article will delve into whether the PTFE tube should touch the nozzle, its role in the printing process, and the best practices for PTFE tube alignment and installation.

Understanding the Role of the PTFE Tube

What is a PTFE Tube?

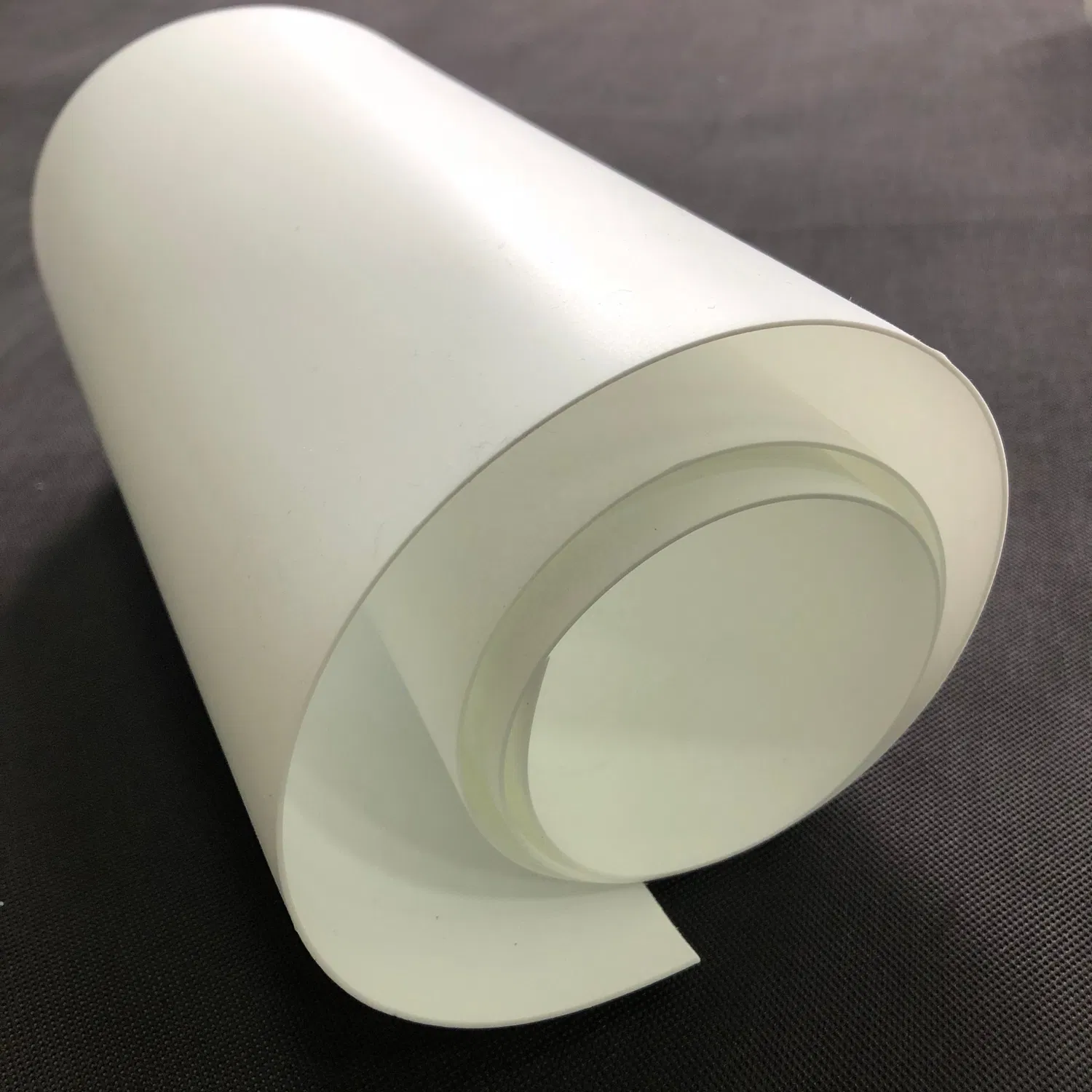

A PTFE tube is a crucial component in many 3D printers, especially those using the Bowden system. This tube acts as a guide for the filament, ensuring it is fed smoothly from the extruder to the hotend.

Why is PTFE Tube Important?

The PTFE tube’s primary function is to reduce friction during the filament’s journey. Its non-stick properties prevent clogging and jamming, which can significantly affect print quality. Moreover, the tube’s alignment and fitting are critical for maintaining consistent extrusion.

Should the PTFE Tube Touch the Nozzle?

PTFE Tube-Nozzle Contact

In most 3D printers, especially those using a Bowden setup, the PTFE tube should be close to the nozzle but not necessarily touch it. The proximity ensures a seamless transition for the filament, reducing the risk of leakage or extrusion issues.

The Importance of Nozzle Gap Adjustment

A small gap between the PTFE tube and the nozzle is often recommended. This gap allows for thermal expansion without causing pressure buildup, which could lead to filament jamming. Proper nozzle gap adjustment is crucial for smooth filament flow and optimal print quality.

Best Practices for PTFE Tube Assembly and Installation

Step-by-Step Guide to Bowden Tube Installation

- Measure the PTFE Tube: Ensure you have the correct length to reach from the extruder to the hotend without excess slack.

- Cut the Tube Precisely: Use a sharp blade to cut the tube at a right angle. A clean cut ensures a better fit and reduces the risk of gaps.

- Insert the Tube Securely: Gently insert the tube into the extruder fitting. Ensure it is seated firmly to prevent any filament leakage.

- Align the Tube with the Nozzle: Adjust the tube so that it is close to the nozzle without applying pressure. This minimizes the risk of damaging the nozzle or the tube.

Ensuring Proper PTFE Tube Fittings

Correct PTFE tube fittings are essential for a reliable 3D printing setup. Use compatible fittings that snugly hold the tube in place. Regularly check these fittings to ensure they remain tight and secure.

PTFE Hotend Guide for Optimal Performance

- Regular Maintenance: Keep the PTFE tube clean and free from debris. Regular inspections can prevent clogs and maintain smooth filament flow.

- Temperature Monitoring: Be mindful of the temperature settings. Excessive heat can deform the PTFE tube, leading to poor performance.

Troubleshooting Common PTFE Tube Issues

Filament Jamming and Clogging

If your filament is jamming, check the PTFE tube for blockages or signs of wear. Replacing a worn tube can resolve many extrusion issues.

Inconsistent Extrusion

Inconsistent extrusion may be due to a misaligned PTFE tube. Ensuring the tube is correctly seated and aligned with the nozzle can improve print consistency.

Leakage at the Hotend

Leakage often occurs when there is a gap between the PTFE tube and the nozzle. Adjusting the tube alignment and ensuring a snug fit can eliminate this problem.

Conclusion

The PTFE tube is a vital component in 3D printing, requiring careful installation and maintenance. While it should be close to the nozzle, avoiding direct contact allows for thermal expansion and prevents filament issues. By following best practices for PTFE tube assembly and alignment, you can enhance your 3D printer’s performance and print quality.

In summary, understanding the relationship between the PTFE tube and the nozzle, coupled with regular maintenance, can lead to a more efficient and reliable 3D printing experience. Always ensure your PTFE tube fittings are secure and that your printer components are in good condition for optimal results.