In the world of industrial applications, the choice of materials can significantly impact the efficiency and durability of operations. One such material that stands out for its versatility and performance is soft PTFE tubing. Known for its unique properties, this flexible Teflon hose has become a staple in various industries. Here, we explore the advantages of using high-quality PTFE tubes.

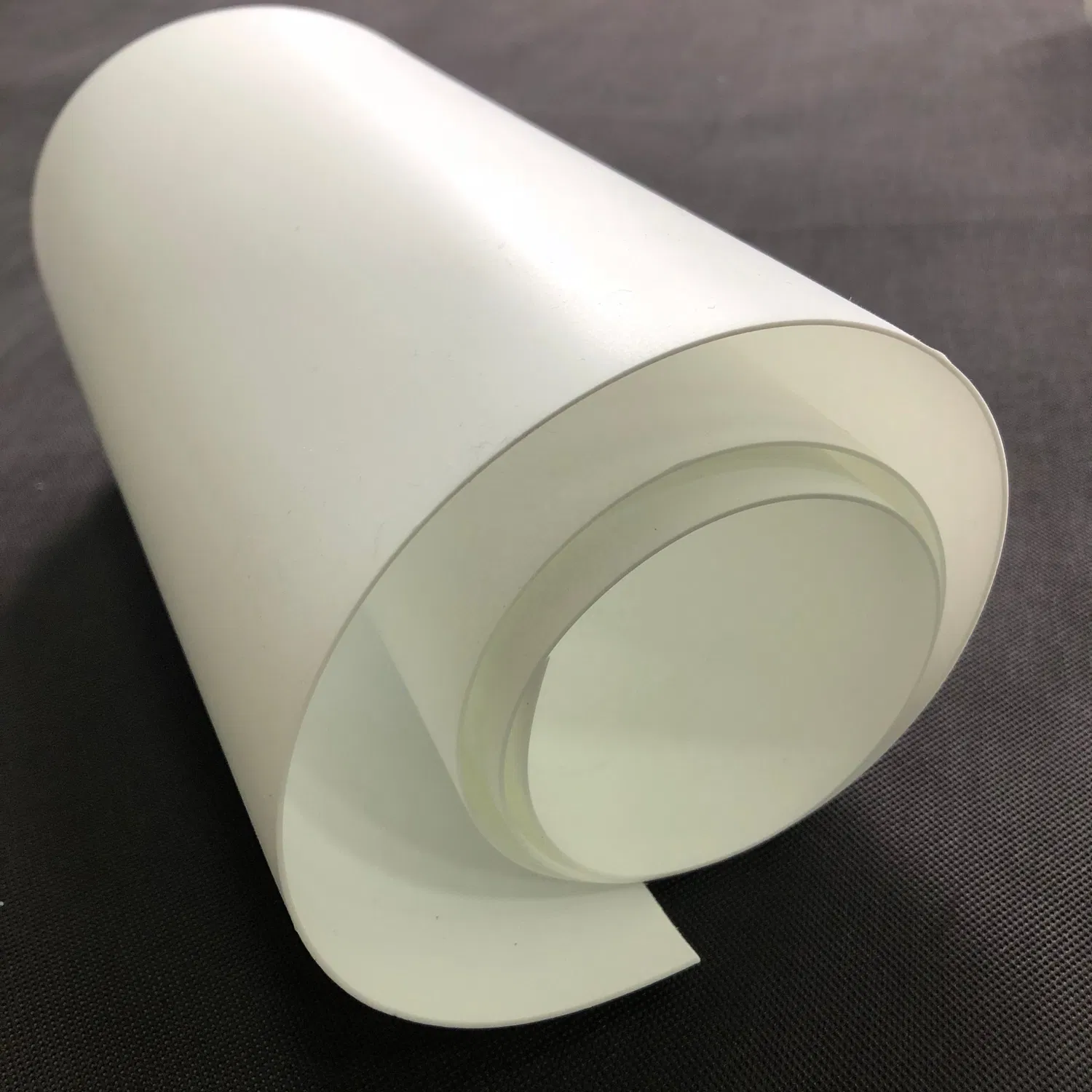

Soft PTFE tubing, also known as flexible PTFE tubing or Teflon tubing, is a type of plastic tube made from polytetrafluoroethylene (PTFE). This material is celebrated for its exceptional chemical resistance and low friction, making it ideal for a range of applications. Unlike rigid tubes, soft PTFE tubing offers flexibility, which is crucial in environments that require adaptability and movement.

Key Benefits of Soft PTFE Tubing

Chemical Resistance

One of the primary advantages of soft PTFE tubing is its resistance to a wide variety of chemicals. This makes it an excellent choice for industries like chemical processing, pharmaceuticals, and food and beverage production. The tubing’s ability to withstand corrosive substances without degrading ensures a longer lifespan and reduces the need for frequent replacements.

Temperature Tolerance

Soft Teflon tubing for industrial use can withstand extreme temperatures, both hot and cold. This property is particularly useful in industries where processes involve high-temperature operations, such as in the automotive or aerospace sectors. The tubing’s ability to maintain its integrity under thermal stress ensures reliable performance.

Flexibility and Bendability

The flexibility of PTFE hose is another significant benefit. Its bendable nature allows it to be used in complex assemblies and systems where space is limited. This adaptability reduces the risk of kinks and breaks, ensuring a smooth flow of liquids or gases through the system. Whether you need a high-quality PTFE tube for a laboratory setup or an industrial plant, its flexibility will be an asset.

Non-Stick Surface

The non-stick property of PTFE makes it difficult for substances to adhere to the tubing’s surface. This feature is particularly advantageous in applications that require cleanliness and contamination prevention, such as in the medical or food industries. It simplifies the cleaning process and ensures the purity of the materials being transported.

Applications of Soft PTFE Tubing

Soft PTFE tubing finds its use in various applications due to its versatile properties. It is commonly utilized in industries such as:

- Chemical Processing: For transporting aggressive chemicals safely.

- Medical Equipment: As conduits for sensitive fluids and gases.

- Food and Beverage: Ensuring hygiene and purity in processing lines.

- Aerospace and Automotive: Withstanding extreme environmental conditions.

In conclusion, the advantages of using soft PTFE tubing make it a preferred choice across multiple sectors. Its chemical resistance, temperature tolerance, flexibility, and non-stick properties provide a reliable solution for complex industrial challenges. Investing in soft Teflon tubes can enhance the efficiency and safety of your operations, offering long-term benefits.