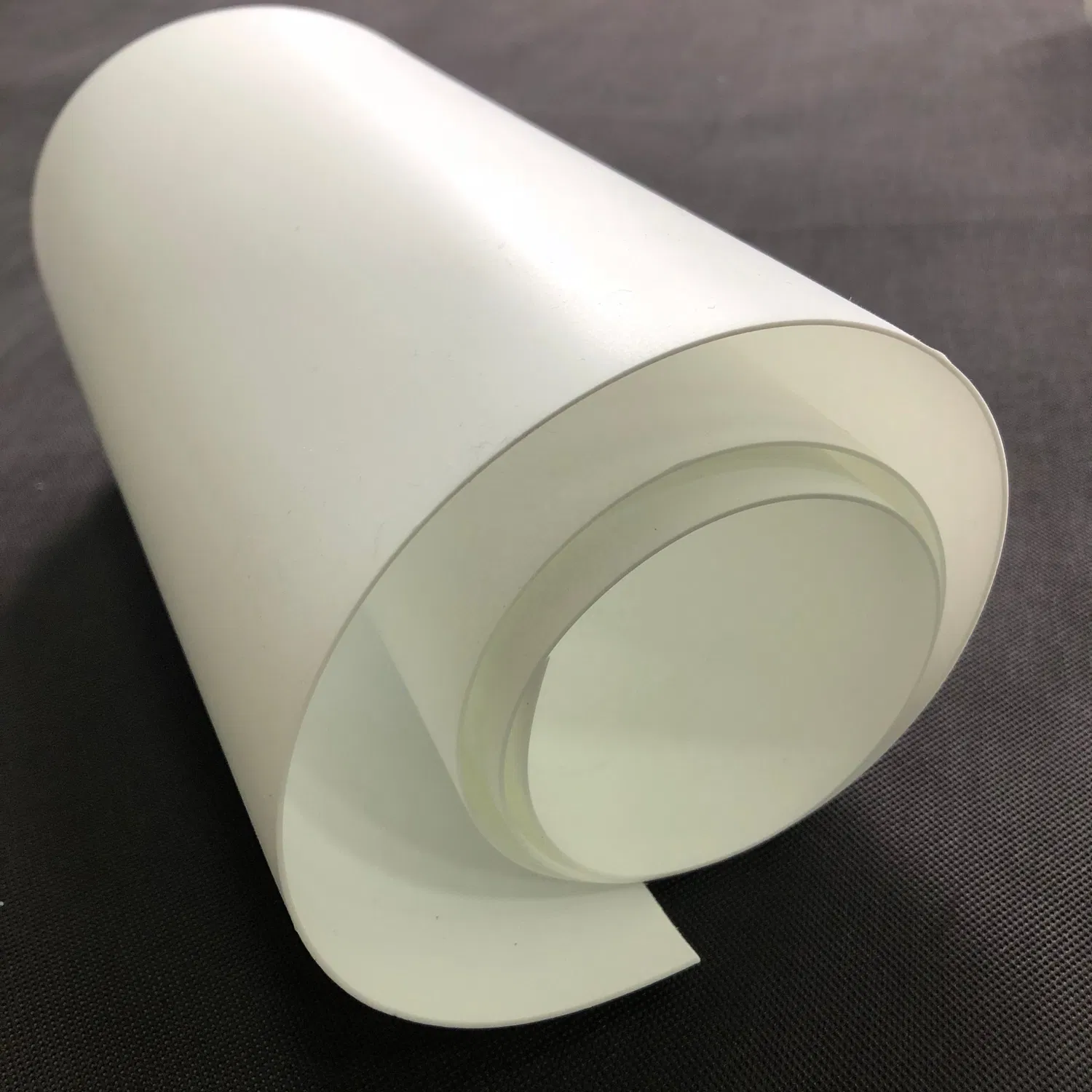

Thin-wall PTFE tubing, also known as Teflon tubing, offers a multitude of advantages for various applications across different industries. Whether you require precision PTFE tubing or a flexible PTFE hose, the benefits of choosing thin-wall PTFE tubing are numerous and significant. In this article, we’ll explore the key advantages of thin-wall PTFE tubing and why it’s a popular choice in many sectors.

PTFE stands for Polytetrafluoroethylene, a synthetic fluoropolymer of tetrafluoroethylene. Known for its non-stick properties, PTFE is more commonly referred to by the brand name Teflon. PTFE tubing is widely used for its resistance to high temperatures, chemical inertness, and excellent electrical insulation properties.

Thin-wall PTFE tubing takes these benefits a step further by providing a lighter and more flexible solution without compromising on performance.

Key Advantages of Thin-Wall PTFE Tubing

Exceptional Chemical Resistance

One of the most remarkable properties of PTFE tubing is its outstanding chemical resistance. PTFE is virtually inert to all chemicals, making it an ideal choice for transporting aggressive solvents, acids, and bases. This resistance ensures that the tubing remains intact and functional even in harsh chemical environments, thus extending the lifespan of your equipment and reducing maintenance costs.

High-Temperature Performance

PTFE tubing can withstand extreme temperatures, ranging from -328°F (-200°C) to 500°F (260°C). This wide temperature range makes it suitable for applications that involve high heat or extreme cold, such as in aerospace, automotive, and electronics industries. The ability to maintain its properties at high temperatures makes PTFE tubing a high-performance choice for critical applications.

Low Coefficient of Friction

PTFE tubing boasts a low coefficient of friction, which means it has excellent non-stick properties. This feature is particularly beneficial in applications where material buildup must be minimized, such as in food processing or medical equipment. The non-stick nature of PTFE prevents clogging and ensures smooth, uninterrupted flow.

Electrical Insulation

Thin-wall PTFE tubing is an excellent electrical insulator, making it suitable for use in electrical and electronic applications. Its high dielectric strength ensures that it can safely insulate wires and cables, even in high-voltage environments. This property is essential for preventing electrical failures and ensuring the safety of electronic equipment.

Flexibility and Lightweight

Compared to other types of tubing, thin-wall PTFE tubing is incredibly flexible and lightweight. This makes it easier to handle and install, particularly in applications with tight spaces or complex routing requirements. The flexibility of PTFE tubing also allows for greater movement and vibration absorption, reducing the risk of damage in dynamic environments.

Biocompatibility

PTFE is biocompatible, meaning it can be used in medical applications without causing adverse reactions in the human body. This property makes thin-wall PTFE tubing a preferred choice for medical devices and equipment, such as catheters and surgical instruments. Its chemical resistance and non-stick properties further enhance its suitability for medical use.

Applications of Thin-Wall PTFE Tubing

Automotive Industry

In the automotive industry, PTFE tubing is used for fuel lines, brake lines, and other fluid transfer systems. Its ability to withstand high temperatures and corrosive substances makes it ideal for these demanding applications. Additionally, the flexibility of thin-wall PTFE tubing allows for easy installation and routing within the vehicle’s tight spaces.

Aerospace Industry

Aerospace applications require materials that can perform under extreme conditions. Thin-wall PTFE tubing’s high-temperature resistance, lightweight nature, and excellent chemical resistance make it suitable for hydraulic systems, fuel lines, and insulation in aircraft and spacecraft.

Electronics and Electrical Applications

In electronics, PTFE tubing is used for wire insulation and component protection. Its electrical insulating properties ensure that electronic devices operate safely and efficiently, even in high-voltage environments. The tubing’s flexibility also allows for the precise placement and routing of wires within complex electronic assemblies.

Chemical Processing

The chemical processing industry benefits from PTFE tubing’s chemical inertness and high-temperature resistance. It is commonly used for transporting aggressive chemicals and solvents, ensuring that the tubing remains intact and functional in harsh environments. The tubing’s non-stick properties also minimize buildup and contamination, which is crucial in chemical processing operations.

Medical Devices

Thin-wall PTFE tubing’s biocompatibility and non-stick nature make it an excellent choice for medical devices. It is used in applications such as catheters, endoscopes, and surgical instruments, where reliability and safety are paramount. PTFE’s chemical resistance ensures that the tubing remains unaffected by sterilization processes, maintaining its integrity and performance in medical environments.

Conclusion

Thin-wall PTFE tubing offers a range of advantages that make it a versatile and reliable choice for various industries. Its exceptional chemical resistance, high-temperature performance, low friction, and excellent electrical insulation properties set it apart as a high-performance material. Whether you need a flexible PTFE hose or precision PTFE tubing, the benefits of thin-wall PTFE tubing make it a popular choice for critical applications in the automotive, aerospace, electronics, chemical processing, and medical industries.

By understanding the advantages and applications of thin-wall PTFE tubing, you can make informed decisions about its use in your specific industry. Its unique properties offer a solution that combines durability, flexibility, and reliability, ensuring optimal performance and efficiency in a wide range of applications.