PTFE gaskets are commonly used in applications where chemical resistance and high-temperature tolerance are required. They are utilized in various industries, including chemical processing, pharmaceuticals, food and beverage, and oil and gas. The ability of PTFE to withstand harsh environments without degrading makes it an invaluable component in these fields. Understanding the properties and applications of PTFE sealing solutions is essential before diving into the gasket making process, as it allows you to tailor the gasket to the specific demands of the application.

Moreover, PTFE’s versatility extends beyond just chemical resistance. Its ability to maintain structural integrity under high pressure and its inert nature make it suitable for use in food processing and medical industries, where contamination must be minimized. A comprehensive understanding of PTFE’s capabilities ensures that the gasket will function effectively in its intended environment, enhancing both safety and efficiency.

Benefits of PTFE Gaskets

- Chemical Resistance: PTFE is resistant to most chemicals, making it ideal for applications involving aggressive substances. This resistance ensures longevity, reducing the need for frequent replacements and thus saving costs over time.

- Temperature Tolerance: It can withstand temperatures ranging from -200°C to +260°C, making it suitable for both extreme cold and heat. This wide temperature range allows PTFE gaskets to be used in diverse environments, from cryogenic applications to high-temperature industrial processes.

- Low Friction: The low coefficient of friction in PTFE reduces wear and tear in dynamic applications. This property is particularly beneficial in systems with moving parts, as it minimizes energy loss and enhances the lifespan of the components involved.

- Non-stick Properties: PTFE’s non-stick nature prevents material build-up, maintaining gasket integrity. This feature is especially useful in environments where deposits could lead to operational inefficiencies or contamination of products.

The Gasket Manufacturing Process

Creating a PTFE gasket involves several steps that require precision and attention to detail. Here’s a comprehensive look at how to make a PTFE gasket. Mastery of these steps is crucial, as even minor errors can lead to gasket failure, resulting in leaks or operational downtime.

Step 1: Preparing the Materials

Before you start, gather all necessary materials and tools. You will need:

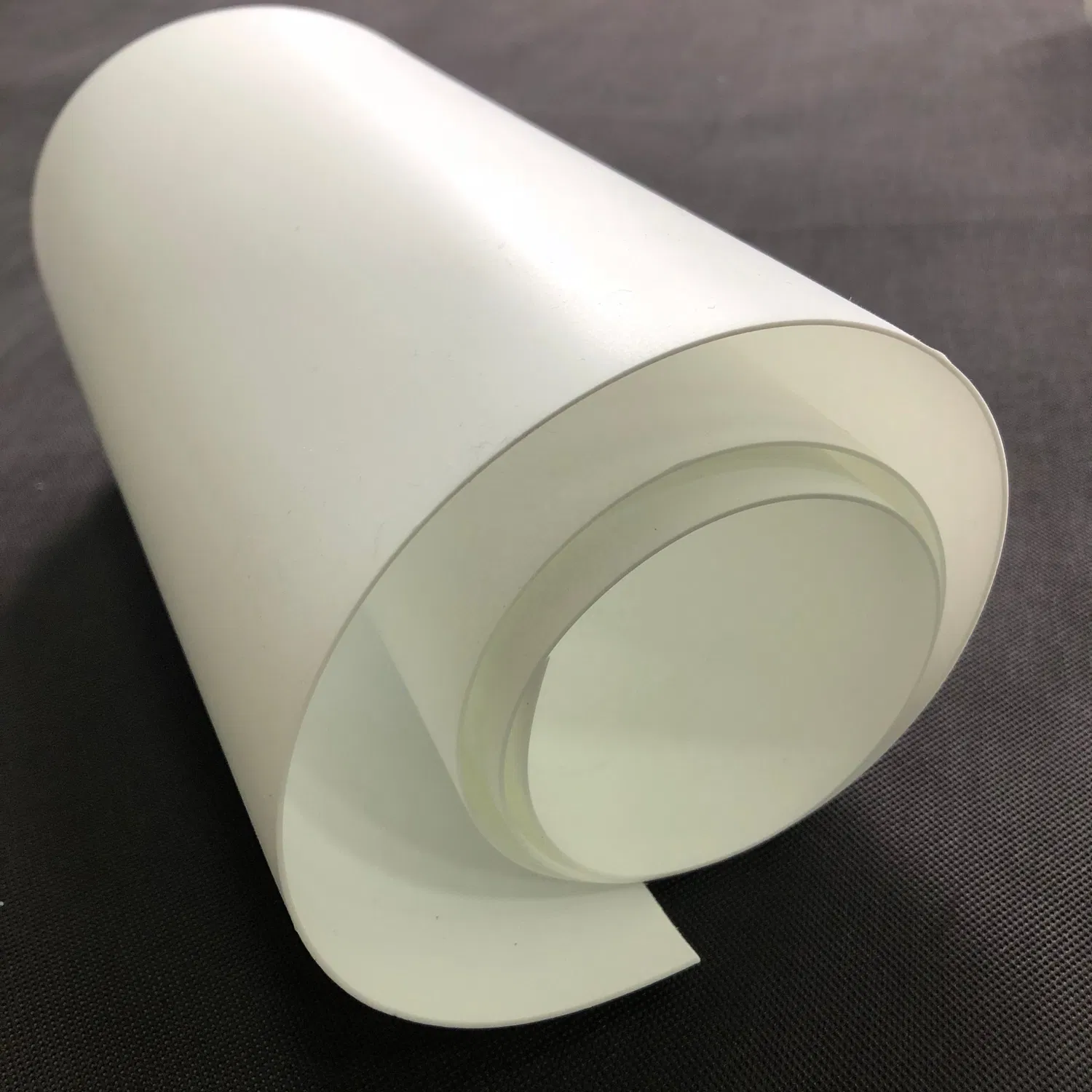

- PTFE sheets or rolls

- A cutting tool (such as a utility knife or gasket cutter)

- Measuring tools (ruler or calipers)

- A marker or pencil for tracing

Ensure your workspace is well-organized and free from distractions, as this will help you maintain focus and accuracy throughout the process. Make sure your work area is clean and free from any contaminants that might affect the gasket’s performance. Contaminants can compromise the gasket’s sealing ability, leading to potential failures.

Step 2: Measuring and Marking

Accurate measurements are crucial for making a PTFE gasket that fits perfectly. Use your measuring tools to determine the dimensions of the gasket you need. Consider factors such as the pressure and temperature it will be exposed to, as these can influence the required thickness and size. Trace the outline of the gasket on the PTFE sheet using a marker or pencil. Ensure that the lines are clear and precise, as this will guide your cutting process.

Additionally, double-check your measurements before marking the PTFE sheet. Mistakes at this stage can lead to wasted materials and time, so it’s worth taking the extra moment to confirm accuracy. A small investment in time now can save significant effort later.

Step 3: Cutting the PTFE Gasket

With the outline marked, proceed to cut the PTFE material. Use a sharp cutting tool to follow the lines closely. A steady hand and a keen eye are essential to achieving a smooth and accurate cut. Take your time to ensure a clean and smooth cut. For complex shapes, a gasket cutter may be more efficient and provide better results. Precision in cutting directly affects the gasket’s ability to seal effectively.

If you are working with thicker PTFE sheets, consider making multiple passes with the cutting tool instead of forcing a single deep cut. This technique reduces the risk of uneven edges and ensures a more professional finish, which is crucial for maintaining a reliable seal.

Step 4: Finishing Touches

Once the gasket is cut, inspect it for any rough edges or imperfections. Use fine sandpaper to smooth any irregularities. This step ensures that the gasket will seal effectively without any leaks. A smooth edge helps create a tighter seal, reducing the likelihood of leaks.

In addition to smoothing the edges, check the surface of the gasket for any scratches or damage that might have occurred during cutting. Addressing these imperfections early on ensures that the gasket will perform optimally once installed.

Step 5: Quality Check

Perform a quality check to ensure that the gasket meets your specifications. Verify the dimensions and check for any visible defects. This step is critical, as even minor defects can lead to significant issues once the gasket is in use. A well-made gasket should have uniform thickness and no signs of damage.

Consider conducting a preliminary fit test by placing the gasket in its intended position. This will help identify any potential issues with fit before full installation, allowing for adjustments without the pressure of operational deadlines.

How to Make PTFE Envelope Gaskets

PTFE envelope gaskets are a specialized type of gasket that combines the chemical resistance of PTFE with the mechanical strength of other materials. These gaskets are ideal for applications where the gasket material needs additional support to withstand higher pressures or abrasive conditions. Here’s how to make a PTFE envelope gasket.

Step 1: Selecting the Core Material

Choose a suitable core material for your application, such as rubber, fiberglass, or metal. The choice of core material depends on the specific requirements of the application, including pressure tolerance and mechanical strength. The core provides structural support to the PTFE envelope, enhancing its durability.

Consider the environmental conditions the gasket will face, as the core material must complement the protective properties of PTFE while providing the necessary mechanical strength. This synergy between materials is crucial for the gasket’s overall performance.

Step 2: Cutting the Core Material

Cut the core material to the desired shape and size. Ensure that it fits snugly within the PTFE envelope. Precision in this step is vital, as a poorly fitting core can compromise the sealing effectiveness and lead to gasket failure.

Using templates or guides can aid in achieving consistent and accurate cuts, especially when producing multiple gaskets. Consistency in the core material’s dimensions ensures uniform performance across all gaskets produced.

Step 3: Creating the PTFE Envelope

Cut a PTFE sheet slightly larger than the core material to create the envelope. The PTFE sheet should be able to wrap around the core completely. This extra material allows for secure sealing of the edges, preventing exposure of the core material to the environment.

Ensure the PTFE envelope is free of tears or holes, as these can compromise the gasket’s integrity. The envelope acts as the primary barrier against chemical exposure, so its quality directly affects the gasket’s performance.

Step 4: Assembling the Gasket

Place the core material in the center of the PTFE sheet. Wrap the PTFE around the core, ensuring complete coverage. Carefully align the edges to ensure a tight seal. Seal the edges of the PTFE envelope to prevent any exposure of the core material. This step is crucial for maintaining the gasket’s chemical resistance and ensuring a leak-proof seal.

Consider using heat or adhesives to secure the envelope, depending on the application requirements. The method chosen should not compromise the PTFE’s properties or the core material’s integrity.

Step 5: Inspect and Test

Inspect the finished PTFE envelope gasket for any gaps or imperfections. Conduct a leak test to verify its sealing performance. Testing under simulated operational conditions can provide insights into the gasket’s reliability and potential areas for improvement.

Regular inspection and testing of gaskets ensure that they meet the necessary standards before being deployed in critical systems. This proactive approach minimizes the risk of failure and enhances overall system reliability.

Conclusion

Making a PTFE gasket requires precision and attention to detail, but with the right approach, it is a manageable task. By following these steps, you can create effective PTFE sealing solutions tailored to your specific needs. Whether you’re working on how to make a PTFE gasket or exploring the intricacies of PTFE envelope gaskets, understanding the process and the materials involved is key to achieving reliable and durable results.

The skills acquired in PTFE gasket manufacturing not only enhance your ability to address a wide range of sealing challenges but also empower you to innovate solutions for complex sealing problems. By mastering the art of PTFE gasket making, you can enhance your ability to tackle a wide range of sealing challenges, ensuring optimal performance in your applications. Embrace these techniques to refine your craft, improve operational efficiency, and contribute to safer, more reliable industrial systems.