In the industrial sector, efficiency and reliability are crucial. One material that stands out for its exceptional properties is PTFE, or polytetrafluoroethylene. Commonly known by the brand name Teflon, PTFE is used in a variety of applications due to its non-stick, heat-resistant, and waterproof qualities. In this article, we’ll explore the advantages of using PTFE submersible tubes in industry, focusing on their durability, chemical resistance, and versatility.

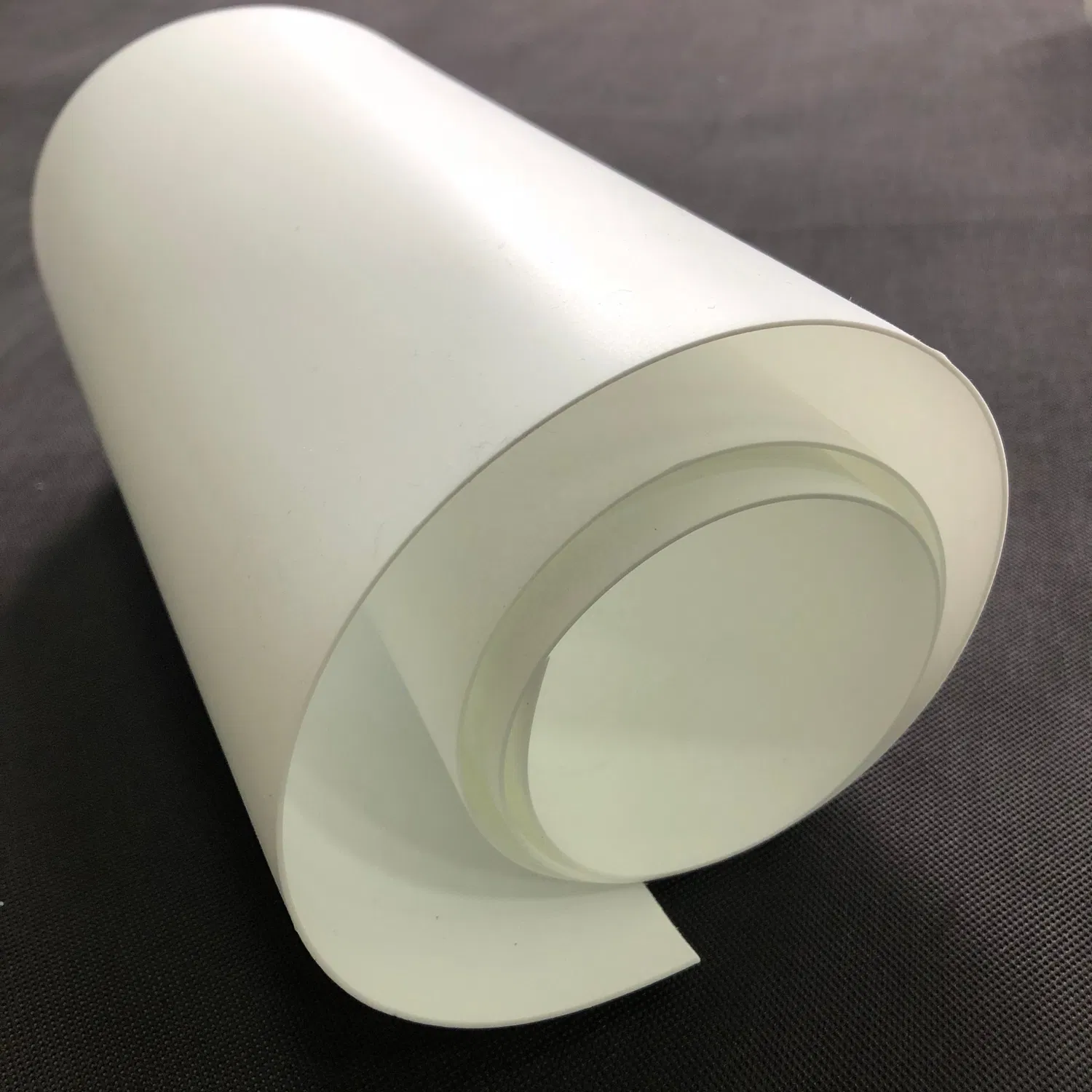

PTFE submersible tubing is a type of industrial tube designed to operate underwater or in environments where it is exposed to moisture. These tubes are made from PTFE, a high-performance fluoropolymer known for its excellent chemical resistance and low friction. PTFE’s unique properties make it ideal for applications that require long-lasting and reliable performance under harsh conditions.

Key Characteristics of PTFE Tubing

PTFE tubing is celebrated for several key properties:

- Chemical Resistance: PTFE is resistant to most chemicals and solvents, making it ideal for use in environments where exposure to corrosive substances is frequent.

- Temperature Resistance: It can withstand extreme temperatures, from very low to very high, without losing its properties.

- Non-Stick Surface: The slick surface of PTFE prevents material build-up, ensuring smooth fluid transfer.

- Electrical Insulation: PTFE is an excellent insulator, making it suitable for electrical applications.

Advantages of Using PTFE Submersible Tubes

Exceptional Durability

One of the primary advantages of PTFE submersible tubes is their durability. In industrial settings, equipment must withstand harsh conditions, and PTFE tubing is up to the task. Its resistance to wear and tear means it can last longer than other materials, reducing the need for frequent replacements and maintenance.

Chemical and Corrosion Resistance

PTFE is renowned for its resistance to a wide range of chemicals. This makes PTFE submersible tubes ideal for use in environments where they might come into contact with aggressive substances. From acids to bases and solvents, PTFE can handle it all. This chemical resistance ensures that the tubing maintains its integrity and performance over time, even when exposed to harsh chemical environments.

High-Temperature Performance

In applications where high temperatures are a concern, PTFE submersible tubes offer a reliable solution. PTFE can withstand temperatures up to 260°C (500°F) without degrading. This makes it suitable for use in industries such as chemical processing, where high-temperature fluid transfer is common.

Versatility in Applications

PTFE submersible tubes are used in a variety of industries due to their versatility:

- Chemical Processing: Ideal for transferring chemicals safely and efficiently.

- Food and Beverage: Used for transferring liquids without contamination.

- Pharmaceuticals: Ensures purity and prevents reaction with pharmaceutical compounds.

- Electronics: Acts as an insulator and prevents moisture ingress.

PTFE in Fluid Transfer and Immersion Applications

PTFE’s low friction coefficient makes it perfect for fluid transfer applications. In submersible pumps and systems, PTFE tubing ensures smooth and efficient flow without clogging. Its non-reactive nature also means that fluids can be transferred without contamination, maintaining the purity of substances.

PTFE vs. Other Materials

When compared to other materials like rubber or metal, PTFE stands out due to its superior performance in harsh environments. While rubber may degrade over time when exposed to chemicals, and metals may corrode, PTFE remains unaffected. This translates to longer service life and lower maintenance costs.

PTFE Submersible Tubes in Action

Consider a chemical plant where corrosive acids are frequently transferred through tubing. Traditional materials may quickly degrade, leading to leaks and potential hazards. PTFE submersible tubes, however, can handle these chemicals with ease, reducing the risk of leaks and ensuring a safe working environment.

In another scenario, a food processing plant requires tubing that won’t react with food products. PTFE’s non-reactive nature ensures that food products remain uncontaminated, preserving quality and safety.

Choosing the Right PTFE Tubing

When selecting PTFE submersible tubes, consider the following:

- Size and Diameter: Ensure the tubing fits the specific requirements of your application.

- Length: Choose the appropriate length for your needs to minimize joints and potential leak points.

- Reinforcement: In some applications, reinforced PTFE tubing may be necessary for added strength.

Conclusion

PTFE submersible tubes offer a range of advantages for industrial applications. Their durability, chemical resistance, and high-temperature performance make them a preferred choice across various industries. By choosing PTFE tubing, industries can ensure efficient, reliable, and safe operations, ultimately leading to reduced downtime and increased productivity.

Whether you are dealing with corrosive chemicals, high temperatures, or require a non-reactive solution, PTFE submersible tubes provide a robust and reliable option. Invest in PTFE tubing for your industrial needs and experience the benefits of advanced material technology.

Incorporating PTFE submersible tubes into your systems not only enhances performance but also ensures compliance with safety and quality standards, making it a sound investment for the future of your business.