When it comes to sealing solutions, PTFE envelope gaskets stand out for their versatility and reliability. These gaskets are widely used in various industries due to their excellent chemical resistance and adaptability. But what exactly are PTFE envelope gaskets, and what makes them so unique? This article will simplify the specifications of these gaskets, helping you understand their applications and benefits.

What are PTFE Envelope Gaskets?

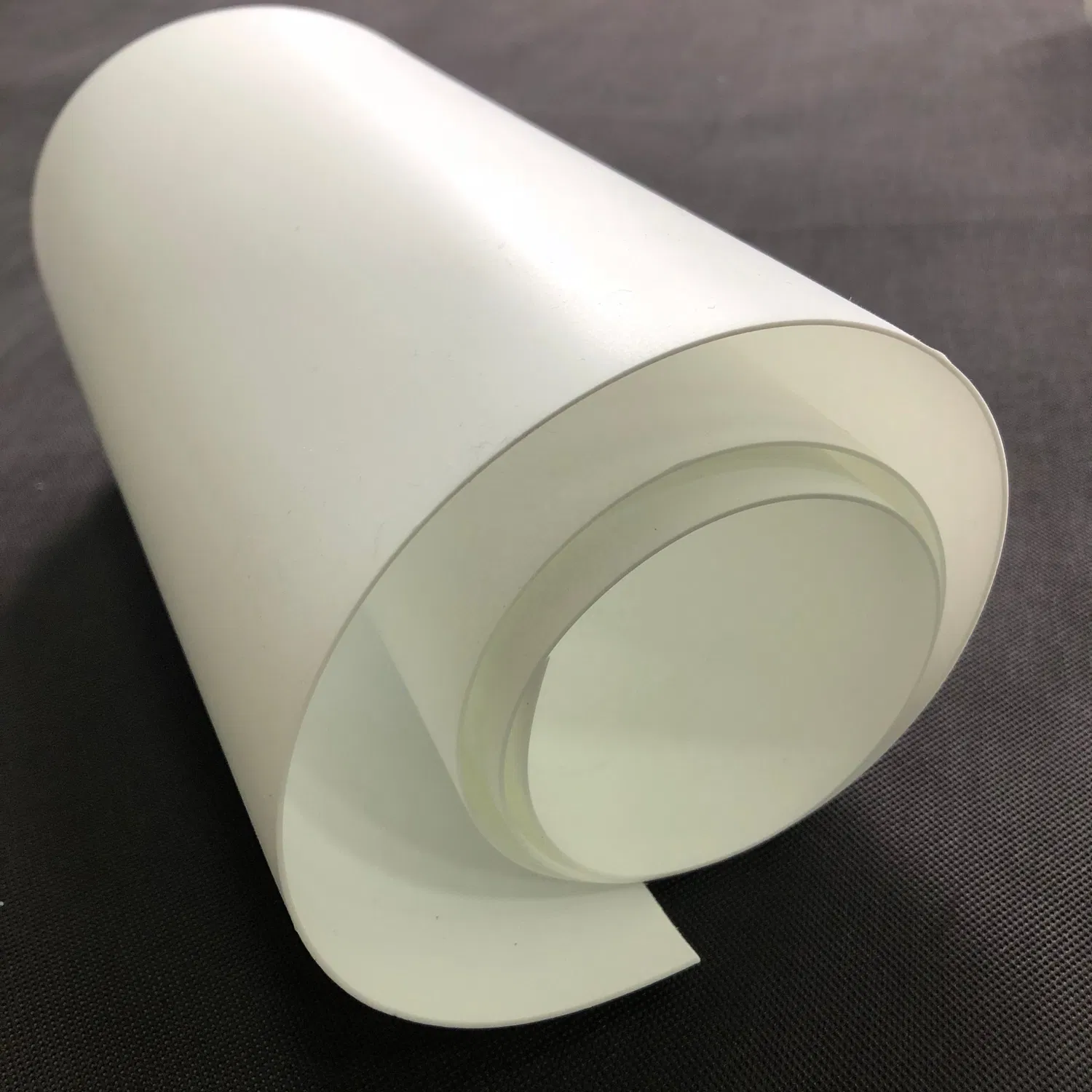

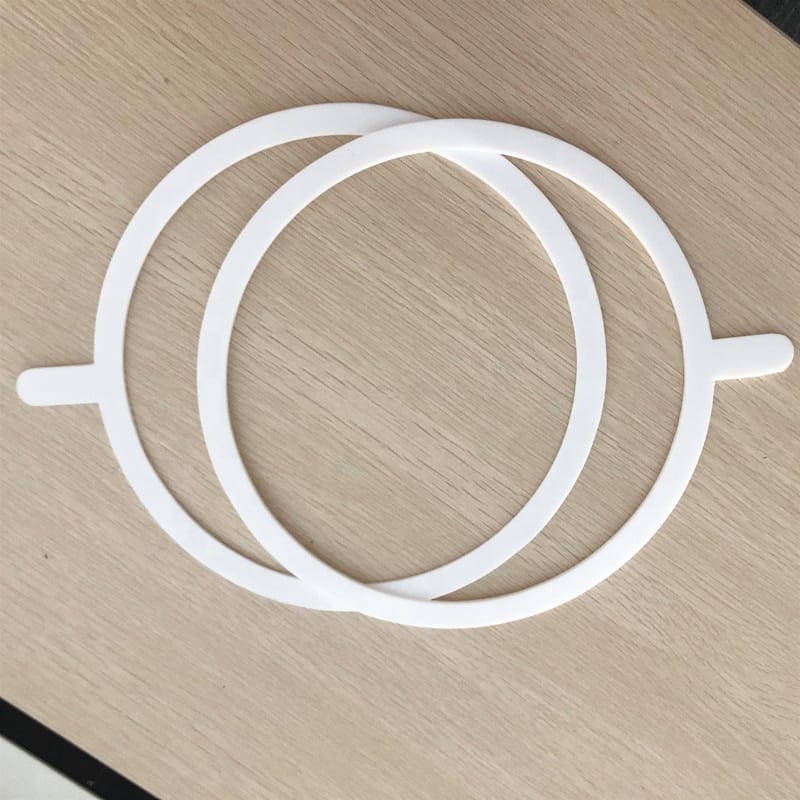

PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer known for its non-reactive nature. This inertness makes it an exceptional material for applications where chemical interaction needs to be minimized. PTFE envelope gaskets are designed with a PTFE jacket that covers a softer core material, such as EPDM or Viton. This combination provides a gasket that is both chemically resistant and flexible, making it suitable for a wide range of applications.

Composition and Structure

The structure of PTFE envelope gaskets features a robust outer layer composed of PTFE, which serves as a barrier against chemical attacks. The inner core is typically composed of materials like EPDM or Viton, which contribute to the gasket’s flexibility and resilience. This dual composition allows the gasket to maintain integrity under various conditions while ensuring a tight seal.

Advantages of PTFE Over Other Materials

PTFE’s unique properties, such as its low friction and non-stick characteristics, make it superior to other gasket materials. Unlike rubber gaskets, PTFE does not degrade quickly, even when exposed to harsh chemicals. This extends the life of the gasket, reducing the need for frequent replacements and maintenance.

Historical Development of PTFE Gaskets

The development of PTFE as a material dates back to the 1930s, with its commercial applications expanding rapidly over the decades. As industries grew more complex, the demand for reliable sealing solutions increased, leading to the innovation of PTFE envelope gaskets. Understanding this historical context helps us appreciate the technological advancements that have made these gaskets indispensable today.

Why Use PTFE Envelope Gaskets?

The primary reason for using PTFE envelope gaskets is their exceptional chemical resistance. They can withstand a broad spectrum of chemicals, which makes them ideal for applications involving corrosive substances. Additionally, these gaskets are known for their low friction and non-stick properties, ensuring a tight seal without sticking to the surfaces they contact.

Chemical Resistance and Durability

PTFE envelope gaskets excel in environments where chemical exposure is a constant concern. Their ability to resist degradation when in contact with acids, bases, and solvents is unparalleled. This durability translates to cost savings and efficiency in operations, as gaskets need not be replaced as frequently as other materials.

Temperature and Environmental Adaptability

These gaskets are also favored for their wide operating temperature range, from cryogenic lows to high-temperature extremes. Whether in a freezing environment or a scorching industrial setting, PTFE envelope gaskets maintain their sealing properties. This adaptability makes them suitable for a wide range of applications, from pharmaceutical manufacturing to oil and gas extraction.

Non-Stick and Low-Friction Benefits

In processes where materials must not adhere to the gasket, the non-stick nature of PTFE is beneficial. This property not only prevents contamination but also simplifies maintenance, as gaskets can be easily removed and replaced without damaging the sealing surfaces. The low friction further enhances performance by reducing wear and tear on the equipment.

Common Types of PTFE Envelope Gaskets

There are various types of PTFE envelope gaskets, each designed to meet specific needs. Let’s explore some common types:

1. PTFE Envelope EPDM Gaskets

These gaskets combine a PTFE outer layer with an EPDM core. EPDM, or ethylene propylene diene monomer, is a synthetic rubber that offers excellent resistance to heat, ozone, and weathering. This makes PTFE envelope EPDM gaskets ideal for applications exposed to harsh environmental conditions.

Environmental and Mechanical Properties

EPDM cores provide resilience and flexibility, accommodating movement and fluctuations in pressure without compromising the seal. This makes them particularly useful in outdoor applications where exposure to the elements is a concern. The combination of EPDM and PTFE ensures longevity and reliability, even in fluctuating conditions.

Versatility in Application

PTFE envelope EPDM gaskets are versatile and can be used in a multitude of industries, from automotive to HVAC systems. Their ability to withstand various environmental factors makes them a preferred choice for engineers seeking robust sealing solutions. This versatility highlights their importance in maintaining the integrity of systems across different sectors.

Cost-Effectiveness and Availability

As EPDM is a commonly available material, PTFE envelope EPDM gaskets are a cost-effective option. Their widespread availability ensures that they are a practical choice for companies looking to balance performance with budget considerations. This economic advantage, coupled with their performance, makes them a popular choice in many industries.

2. PTFE Envelope Viton Gaskets

Viton is another type of synthetic rubber known for its high resistance to extreme temperatures and chemicals. PTFE envelope gaskets with a Viton core are suitable for applications involving aggressive chemicals and high-temperature environments.

High-Temperature Resistance

Viton’s ability to withstand high temperatures without losing its sealing capabilities is one of its most significant advantages. This makes PTFE envelope Viton gaskets ideal for use in environments where temperatures regularly exceed normal levels, such as in chemical processing plants.

Chemical Compatibility

The chemical compatibility of Viton allows these gaskets to be used with a wide range of aggressive substances. In industries where chemical exposure is a daily challenge, such as petrochemicals, PTFE envelope Viton gaskets offer a reliable sealing solution that can handle the most demanding conditions.

Application in Specialized Industries

Due to their robust properties, PTFE envelope Viton gaskets find applications in specialized industries, including aerospace and automotive sectors. Their ability to maintain performance under stress makes them invaluable in scenarios where failure is not an option.

3. PTFE Envelope FKM Gaskets

FKM is similar to Viton but offers even greater chemical resistance. PTFE envelope FKM gaskets are often used in the chemical processing industry, where they must withstand aggressive and volatile chemicals.

Enhanced Chemical Resistance

The superior chemical resistance of FKM cores in PTFE envelope gaskets makes them suitable for extremely harsh environments. This enhanced resistance ensures that the gaskets can maintain a seal even when exposed to the most corrosive substances.

Longevity and Reliability

FKM gaskets are known for their long service life, reducing the need for frequent replacements. This reliability is crucial in industries where downtime can lead to significant losses, ensuring that operations run smoothly with minimal interruptions.

Integration in Safety-Critical Systems

Given their robustness, PTFE envelope FKM gaskets are often integrated into safety-critical systems where the integrity of the seal is paramount. This includes applications in the chemical processing and oil and gas industries, where leaks could have catastrophic consequences.

Key Specifications of PTFE Envelope Gaskets

Understanding the specifications of PTFE envelope gaskets is crucial for selecting the right gasket for your needs. Here are some key specifications to consider:

Thickness and Dimensions

PTFE envelope gaskets come in various thicknesses and dimensions to suit different applications. It’s essential to select the right size to ensure a proper seal. Refer to the PTFE gasket size chart or consult with PTFE envelope gasket manufacturers for guidance.

Customization for Specific Needs

Manufacturers offer customization options to meet the specific requirements of different applications. Whether you require a specific thickness or a unique shape, collaborating with a supplier that offers customization ensures the gasket perfectly fits your needs.

Importance of Accurate Sizing

Accurate sizing is crucial for the gasket’s optimal performance. An ill-fitting gasket can lead to leaks, inefficiencies, and even damage to equipment. Therefore, precise measurements and adherence to specifications are critical to achieving the desired sealing performance.

Material Considerations

The choice of core material can also affect the thickness and dimensions of the gasket. Understanding the properties of the materials used can help in selecting the right configuration for your specific application.

Chemical Resistance

One of the most critical specifications of PTFE envelope gaskets is their chemical resistance. They can withstand a wide range of chemicals, including acids, bases, and solvents. This makes them an excellent choice for industries such as pharmaceuticals, food processing, and petrochemicals.

Testing and Standards

Chemical resistance is often verified through rigorous testing and adherence to industry standards. These tests ensure that the gaskets can withstand the specific chemicals they will encounter in their intended applications. Understanding these standards helps you select the right gasket for your specific needs.

Industry-Specific Requirements

Different industries have unique chemical resistance requirements. For example, food processing might require resistance to specific cleaning agents, while the petrochemical industry might need resistance to hydrocarbons. Identifying these needs is crucial in selecting the right gasket.

Long-Term Performance

The long-term performance of a gasket is often determined by its chemical resistance. Gaskets that fail under chemical exposure can lead to costly repairs and downtime. Ensuring that a gasket can withstand its operating environment over time is key to maintaining system integrity.

Temperature Range

PTFE envelope gaskets can operate in a broad temperature range, typically from -200°C to 260°C (-328°F to 500°F). This allows them to perform well in both cryogenic and high-temperature applications.

Cryogenic Applications

In cryogenic applications, the ability of a gasket to maintain flexibility and seal integrity at extremely low temperatures is crucial. PTFE envelope gaskets are often used in such scenarios, ensuring that systems remain leak-free even under these challenging conditions.

High-Temperature Environments

High-temperature resistance ensures that the gasket does not degrade or lose its sealing capabilities when exposed to heat. This makes PTFE envelope gaskets suitable for use in engines, boilers, and other high-temperature applications.

Thermal Cycling and Stability

The ability to withstand thermal cycling—repeated heating and cooling—without losing performance is another essential feature. PTFE envelope gaskets offer stability under these conditions, ensuring continuous performance in dynamic environments.

Pressure Rating

The pressure rating of a PTFE envelope gasket depends on its design and the materials used in its construction. Be sure to check the pressure specifications to ensure the gasket can handle the pressure levels in your application.

Understanding Pressure Limits

Pressure ratings indicate the maximum pressure a gasket can withstand without failing. Understanding these limits helps in selecting a gasket that can handle the operational pressures of your system without risking leaks or blowouts.

Impact of Core Materials on Pressure Ratings

The choice of core material plays a significant role in determining the pressure rating of a gasket. Materials like Viton and FKM offer higher pressure resistance, making them suitable for more demanding applications.

Application-Specific Pressure Requirements

Different applications have varied pressure requirements. For instance, systems operating under vacuum conditions may have different needs compared to those under high-pressure conditions. Selecting a gasket that meets these specific requirements is essential for optimal performance.

Applications of PTFE Envelope Gaskets

PTFE envelope gaskets are used in a wide range of industries due to their versatility and reliability. Some common applications include:

Chemical Processing

With their excellent chemical resistance, PTFE envelope gaskets are ideal for sealing applications involving aggressive chemicals. They prevent leaks and contamination, ensuring safe and efficient processing in chemical plants.

Role in Safety and Efficiency

In chemical processing, safety and efficiency are paramount. PTFE envelope gaskets contribute to both by providing reliable seals that prevent hazardous leaks. This reliability is crucial in maintaining safe working environments and optimizing production processes.

Compatibility with Chemical Media

The compatibility of PTFE envelope gaskets with various chemical media ensures that they can be used in a wide range of chemical reactions and processes. This versatility makes them an indispensable component in the chemical industry.

Maintenance and Reliability

The durability of PTFE envelope gaskets reduces the need for frequent maintenance and replacements. This reliability translates to lower operational costs and increased uptime, benefiting the overall productivity of chemical processing facilities.

Food and Beverage

These gaskets are non-reactive and safe for food contact, making them suitable for use in the food processing and packaging industries. Their non-stick properties ensure that food products do not adhere to the gaskets, maintaining hygiene and quality.

Importance of Hygiene and Safety

In the food and beverage industry, maintaining hygiene and safety is critical. PTFE envelope gaskets contribute to this by providing non-reactive and easy-to-clean sealing solutions, ensuring that products remain uncontaminated.

Compliance with Food Safety Standards

PTFE envelope gaskets used in food applications are often tested and certified to meet strict food safety standards. This compliance ensures that they are safe for use in food processing environments, protecting consumer health.

Efficiency in Processing

The non-stick properties of PTFE envelope gaskets enhance efficiency in food processing by preventing product buildup. This results in cleaner operations and reduces the need for frequent cleaning and maintenance, optimizing production processes.

Pharmaceuticals

PTFE envelope gaskets are used in pharmaceutical manufacturing processes where cleanliness and chemical resistance are crucial. They ensure that drugs are produced in contamination-free environments, meeting stringent industry standards.

Contamination Prevention

In pharmaceutical manufacturing, preventing contamination is crucial for ensuring the safety and efficacy of products. PTFE envelope gaskets help achieve this by providing reliable seals that prevent contaminants from entering the manufacturing process.

Compliance with Regulatory Standards

Pharmaceutical applications require adherence to strict regulatory standards. PTFE envelope gaskets are often designed and tested to meet these standards, ensuring compliance and maintaining product quality.

Versatility in Pharmaceutical Applications

The versatility of PTFE envelope gaskets allows them to be used in various pharmaceutical applications, from drug manufacturing to packaging. This adaptability ensures that they can meet the diverse needs of the industry.

Oil and Gas

Their ability to withstand extreme temperatures and pressures makes them suitable for sealing applications in the oil and gas industry. They prevent leaks and ensure the safe and efficient operation of equipment.

High-Pressure and High-Temperature Resistance

The oil and gas industry operates in extreme conditions that require robust sealing solutions. PTFE envelope gaskets provide the necessary resistance to high pressures and temperatures, ensuring that systems remain leak-free.

Reliability in Critical Applications

In the oil and gas sector, the reliability of sealing solutions is critical to preventing catastrophic failures. PTFE envelope gaskets offer the dependability needed to maintain operational integrity in these demanding environments.

Adaptability to Harsh Conditions

The harsh conditions encountered in oil and gas extraction and processing demand gaskets that can withstand environmental challenges. PTFE envelope gaskets are designed to meet these challenges, offering performance and longevity.

Choosing the Right PTFE Envelope Gasket Supplier

When selecting a supplier for PTFE envelope gaskets, consider the following factors:

Quality Assurance

Ensure that the supplier provides high-quality PTFE envelope gaskets that meet industry standards and specifications. Look for certifications and quality control processes that guarantee the reliability of their products.

Importance of Certifications

Certifications such as ISO standards indicate that a supplier adheres to quality management practices. These certifications ensure that the products meet industry benchmarks, ensuring reliability and performance.

Quality Control Processes

A supplier with robust quality control processes ensures that each gasket meets the specified standards before reaching the customer. This attention to detail helps avoid defects and inconsistencies, providing confidence in the product’s performance.

Supplier Reputation and Track Record

A supplier’s reputation and track record in the industry can offer insights into their reliability. Partnering with a well-regarded supplier can provide peace of mind and ensure that you receive high-quality gaskets.

Range of Products

Select a supplier that offers a diverse range of PTFE envelope gaskets to cater to your specific requirements. Whether you require standard sizes or custom gaskets, a diverse product range is essential for meeting your needs.

Availability of Custom Solutions

The ability to provide custom solutions is a critical factor when selecting a supplier. A supplier that can tailor products to meet specific requirements ensures that you receive gaskets perfectly suited to your applications.

Comprehensive Product Line

A comprehensive product line indicates that a supplier can meet diverse needs across different industries. This versatility ensures that you can source all your gasket requirements from a single, reliable supplier.

Responsive to Market Trends

Suppliers that keep up with market trends and innovations can offer the latest advancements in gasket technology. This responsiveness ensures that you have access to cutting-edge solutions that enhance performance and efficiency.

Technical Support

A reputable supplier should offer technical support and guidance in selecting the right gaskets for your applications. They should be able to provide detailed specifications and answer any questions you may have.

Importance of Expert Guidance

Expert guidance from a knowledgeable supplier can help you navigate the complexities of selecting the right gasket. This support ensures that you make informed decisions that optimize performance and cost-effectiveness.

Availability of Detailed Specifications

Access to detailed specifications and documentation is crucial for understanding the capabilities and limitations of a gasket. A supplier that provides comprehensive information empowers you to make the best choice for your applications.

Ongoing Customer Support

Ongoing customer support beyond the point of sale is essential for addressing any issues that may arise. A supplier committed to customer service can assist throughout the product’s lifecycle, ensuring customer satisfaction and reliability.

Conclusion

PTFE envelope gaskets are an excellent choice for sealing applications that require chemical resistance, flexibility, and reliability. By understanding their specifications and applications, you can make informed decisions when selecting the right gasket for your needs. Whether you’re in the chemical, food, pharmaceutical, or oil and gas industry, PTFE envelope gaskets can provide the sealing solution you require.

By partnering with reputable PTFE envelope gasket suppliers, you can ensure that you receive high-quality products that meet your specific needs and contribute to the success of your operations. Investing in the right gaskets not only enhances performance but also ensures safety and efficiency across various applications.