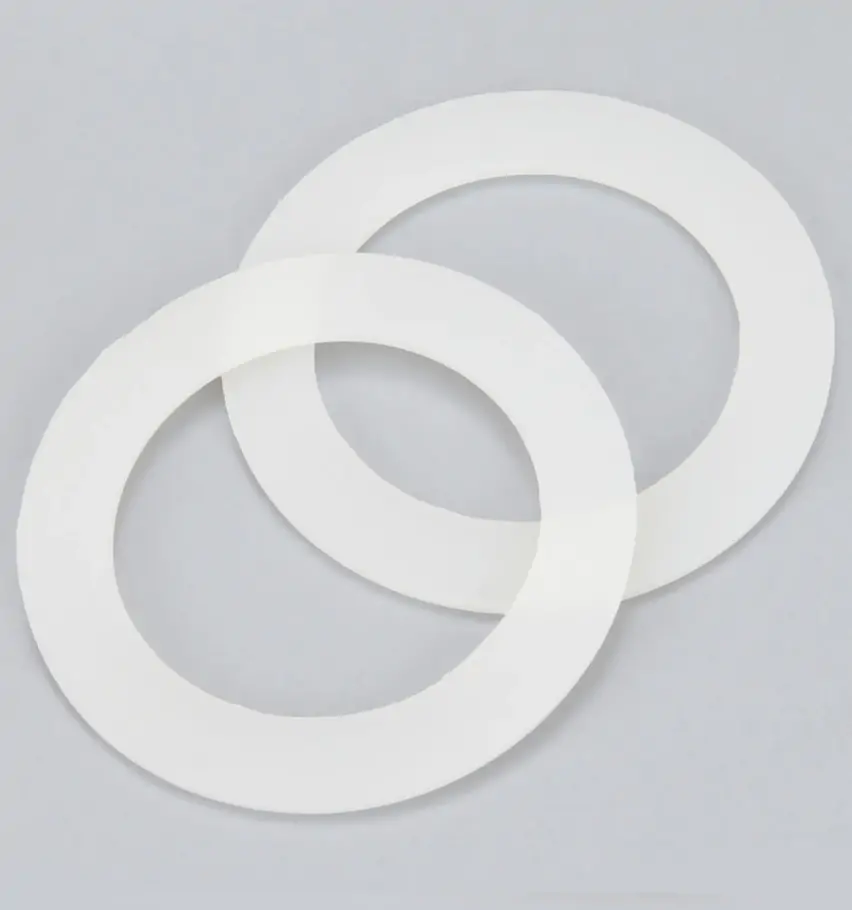

PolyTetraFluoroEthylene (PTFE) gaskets are making waves across various industries due to their incredible properties and versatile applications. These gaskets are not only known for their excellent sealing capabilities but also for their resistance to high temperatures and corrosive substances. In this article, we will delve into the applications of PTFE gasket in different industries and explore why they are favored for specific tasks.

PTFE is a synthetic fluoropolymer of tetrafluoroethylene. Its properties make it an ideal choice for gasket material. Here are some key attributes of PTFE gaskets:

- Chemical Resistance: PTFE gaskets are highly resistant to a wide range of chemicals, making them suitable for use in environments where they are exposed to corrosive fluids.

- Temperature Resistance: These gaskets can withstand extremely high temperatures, making them perfect for applications that involve heat.

- Non-reactive Nature: PTFE is non-reactive, which is why it is used in applications where gaskets must not react with the substances they come into contact with.

- Low Friction: The low coefficient of friction of PTFE makes it a preferred choice in applications where smooth movement is necessary.

PTFE Gasket Applications in Different Industries

PTFE Gasket in the Chemical Industry

The chemical industry often deals with aggressive and corrosive substances. PTFE gaskets are highly valued here for their chemical resistance. These gaskets ensure that seals remain intact and do not degrade when exposed to harsh chemicals, thus maintaining the integrity of chemical processes.

PTFE Gasket in Pharmaceutical Equipment

In the pharmaceutical industry, maintaining purity and preventing contamination is crucial. PTFE gasket is used in pharmaceutical equipment because they do not react with the substances they come into contact with, ensuring that there is no contamination of the products. Moreover, their ability to withstand sterilization processes makes them invaluable in this field.

PTFE Gasket Food Grade Applications

PTFE gasket is also widely used in the food industry. Food-grade PTFE gasket comply with regulatory standards and are safe for contact with food substances. They are used in food processing equipment to provide safe and effective seals, ensuring that there is no contamination or leakage.

PTFE Gasket for Corrosive Fluids

Industries that handle corrosive fluids, such as petrochemical and oil refineries, often rely on PTFE gaskets. Due to their ability to resist chemical degradation, PTFE gaskets provide effective sealing solutions that prevent leaks and ensure the safe handling of corrosive substances.

PTFE Gasket Sealing Applications

One of the primary uses of PTFE gaskets is in sealing applications. Their ability to maintain a tight seal even under extreme conditions makes them ideal for various industries. Whether it’s preventing leaks in pipelines or ensuring the containment of gases, PTFE gaskets are up to the task.

PTFE Gasket for High Temperature Applications

PTFE gaskets are designed to withstand high temperatures, making them suitable for applications that involve heat. They are used in industries like aerospace and automotive where components are exposed to high thermal conditions. PTFE gaskets provide reliable sealing that can endure these temperatures without degrading.

Versatility and Customization

PTFE gaskets can be customized to meet specific application requirements. Whether it’s a particular size, shape, or thickness, PTFE gaskets can be tailored to fit unique needs. This versatility makes them suitable for a wide range of applications across different industries.

Benefits of Using PTFE Gaskets

- Durability: PTFE gaskets have a long lifespan due to their resistance to wear and tear.

- Safety: Their non-reactive nature ensures that they do not contribute to any chemical reactions that could compromise safety.

- Efficiency: By providing a reliable seal, PTFE gaskets improve the efficiency of equipment and processes.

- Cost-Effective: Although they may have a higher initial cost, their durability and performance make them a cost-effective choice over time.

Conclusion

PTFE gaskets are a critical component in many industries due to their impressive properties and versatile applications. From the chemical and pharmaceutical industries to food processing and high-temperature environments, PTFE gaskets provide reliable and efficient sealing solutions. Their ability to withstand harsh conditions while maintaining integrity makes them an indispensable part of modern industrial applications.

As industries continue to evolve, the demand for reliable sealing solutions like PTFE gasket is expected to grow. Understanding their properties and applications can help businesses choose the right gasket material for their specific needs, ensuring safety, efficiency, and longevity in their operations.