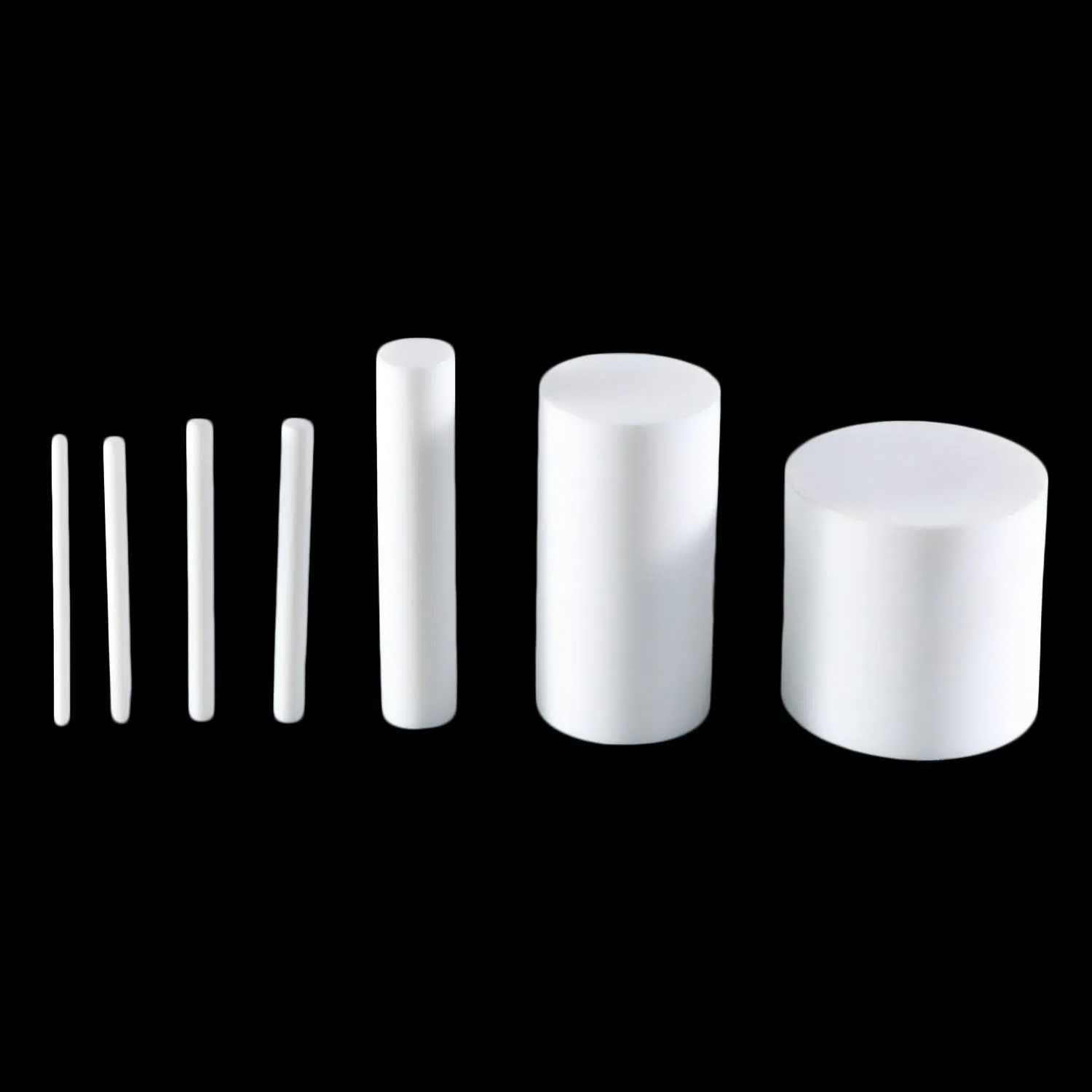

When it comes to selecting a replacement PTFE tube, making the right choice is crucial for ensuring optimal performance and longevity of your equipment. PTFE, also known as Teflon, is renowned for its exceptional properties, including high temperature resistance, chemical inertness, and non-stick characteristics. Whether you need PTFE tube fittings for industrial applications, a Teflon tube for a printer, or a Bowden tube replacement for 3D printing, understanding the different types and specifications can help you make an informed decision.

PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer of tetrafluoroethylene. It’s a versatile material used in various industries due to its unique properties. Here’s why PTFE tubing is often the go-to choice:

Key Characteristics of PTFE Tubing

- High Temperature Resistance: PTFE tubes can withstand temperatures ranging from -200°C to +260°C, making them suitable for applications involving extreme heat.

- Chemical Resistance: PTFE is resistant to almost all industrial chemicals, making it ideal for transporting aggressive substances without degradation.

- Non-Stick Surface: Its low friction coefficient ensures that substances don’t easily adhere to the tube’s surface, which is beneficial in maintaining flow efficiency.

- Electrical Insulation: PTFE is an excellent insulator, often used in electrical applications to protect wires and prevent short circuits.

Applications of PTFE Tubing

PTFE tubing finds its application in a variety of fields, including:

- Industrial Use: As a high-temperature tube, it’s used in chemical processing, oil and gas industries, and more.

- Printing: Teflon tubes are common in printers for smooth filament feeding.

- 3D Printing: Bowden tube replacements are critical for guiding filaments to the extruder in 3D printers.

- Laboratory: Its chemical resistance makes it a staple in labs for transporting aggressive reagents.

Factors to Consider When Choosing PTFE Tubing

Selecting the right PTFE tubing requires careful consideration of several factors to ensure compatibility with your specific application.

Diameter and Wall Thickness

The internal and external diameters of the PTFE tube must match the fittings and requirements of your system. The wall thickness impacts the tube’s flexibility and pressure rating.

Temperature Range

Ensure the PTFE tube can handle the operational temperature of your application. For high-temperature environments, opt for tubes specifically rated for such conditions.

Chemical Compatibility

While PTFE is resistant to most chemicals, it’s essential to verify compatibility, especially in unique or extreme chemical environments. Consult with PTFE tube suppliers for guidance if necessary.

Pressure Rating

Consider the working pressure of your application. Tubes with thicker walls generally offer higher pressure ratings, which is crucial in high-pressure systems.

Flexibility and Bend Radius

Evaluate the flexibility requirements and the minimum bend radius needed for your setup. Applications with tight spaces or intricate routing require more flexible tubing.

PTFE Tube Fittings and Installation

The right fittings are essential for ensuring a secure connection and leak-free operation.

Types of Fittings

PTFE tube fittings come in various types, including compression fittings, flare fittings, and push-to-connect fittings. The choice depends on the application and the ease of installation required.

Installation Tips

- Cutting: Use a sharp blade to cut the PTFE tube cleanly, ensuring a smooth edge to prevent leaks.

- Fitting Attachment: Follow the manufacturer’s guidelines for attaching fittings to avoid damaging the tube.

- Testing: After installation, conduct pressure and leak tests to ensure the system’s integrity.

Maintenance and Replacement

Regular maintenance and timely replacement of PTFE tubing can prevent system failures and extend the life of your equipment.

Signs of Wear and Tear

Inspect PTFE tubes regularly for signs of wear, such as cracks, discoloration, or reduced flexibility. These are indicators that a replacement may be necessary.

PTFE Pipe Repair

In some cases, PTFE pipe repair might be an option. However, for critical applications, replacement is often the safer choice.

Bowden Tube Replacement

For 3D printers, a Bowden tube replacement might be needed if filament feeding becomes inconsistent. Ensure the replacement tube matches the original specifications for optimal performance.

Sourcing Quality PTFE Tubing

Choosing a reliable supplier is crucial for obtaining high-quality PTFE tubing that meets industry standards.

Finding Reputable PTFE Tube Suppliers

Look for suppliers with a proven track record and positive reviews in supplying industrial PTFE tubes, chemical-resistant tubing, and other specific needs.

Customization Options

Some applications may require customized PTFE tubing solutions. Reputable suppliers often offer customization options to meet unique specifications.

Conclusion

Selecting the right replacement PTFE tube requires understanding your application’s specific needs and the properties of PTFE tubing. By considering factors like temperature, chemical compatibility, and pressure requirements, you can ensure a reliable and efficient operation. Regular maintenance and timely replacement further contribute to the longevity and effectiveness of your systems.

In the ever-evolving world of industrial applications, making informed choices about PTFE tubing can significantly impact your operations’ success and efficiency. Choose wisely and keep your systems running smoothly.