When it comes to ensuring the integrity of piping systems, machinery, or even household appliances, the choice of gasket material can be a pivotal decision. Two heavyweights in the world of sealing solutions are PTFE (Polytetrafluoroethylene) and Silicone gaskets. Each comes with its own set of attributes, making them ideal for certain applications yet potentially unsuitable for others. Picture this: You’re managing a high-stakes industrial project, where a simple leak can trigger not only expensive downtime but also safety hazards. Choosing between a PTFE and silicone gasket isn’t just about materials; it’s about making a strategic decision that could make or break your operation.

In recent years, industries across the globe have navigated the complexities of selecting the right gasket material. From the pharmaceutical sector, where cleanliness and chemical resistance take center stage, to the automotive industry, which demands flexibility and temperature resilience, understanding the strengths and limitations of these materials is crucial. Did you know that PTFE gaskets are renowned for their superb chemical resistance and low friction properties, while silicone gaskets shine in their ability to withstand extreme temperature shifts? Delving into the nuances of PTFE vs silicone gaskets equips you with the knowledge to not only meet but exceed the demands of your specific application.

Chemical Resistance and Compatibility

Selecting a gasket often starts with evaluating chemical resistance, especially in processes handling corrosive or reactive fluids. PTFE gaskets excel in this category thanks to their outstanding inertness. They can resist virtually all acids, alkalis, solvents, and aggressive compounds across a broad pH range (0–14), making them a top choice for chemical processing, petroleum refining, and laboratory equipment. In the debate of ptfe vs silicone gasket, PTFE’s remarkable stability means minimal risk of material degradation, swelling, or contamination over prolonged exposure.

Silicone gaskets, on the other hand, offer moderate chemical resistance but can be vulnerable to petroleum-based oils, strong acids, and certain solvents. While they perform well with water, mild detergents, and alcohols, they may swell or lose mechanical integrity when in contact with hydrocarbons or chlorinated compounds. In food and beverage applications, medical devices, and cleanroom environments where aggressive chemicals are not present, silicone remains a cost-effective and compliant solution. Ultimately, understanding the specific fluid media and operating conditions is key when weighing chemical compatibility in the ptfe vs silicone gasket decision.

Temperature Resilience and Flexibility

When extreme temperatures are in play, your gasket material must maintain both elasticity and seal quality. PTFE gaskets boast an impressive operating range from approximately –200°C to +260°C, making them suitable for cryogenic applications as well as high-temperature steam systems. However, PTFE can become brittle at ultra-low temperatures and may exhibit cold flow (creep) under sustained compressive loads, which can affect long-term sealing performance if not properly supported.

Silicone gaskets offer excellent flexibility across a wide temperature band, typically from –60°C to +200°C. Their rubber-like properties ensure consistent rebound resilience and minimal compression set, even after repeated thermal cycling. This makes silicone ideal for automotive engine compartments, HVAC systems, and appliances that experience rapid heating and cooling. While silicone cannot match PTFE’s upper temperature ceiling or inertness, its superior pliability and lower tendency to cold flow often give it an edge where dynamic sealing and moderate temperature resistance are required in the ptfe vs silicone gasket comparison.

Seal Integrity and Leak Prevention

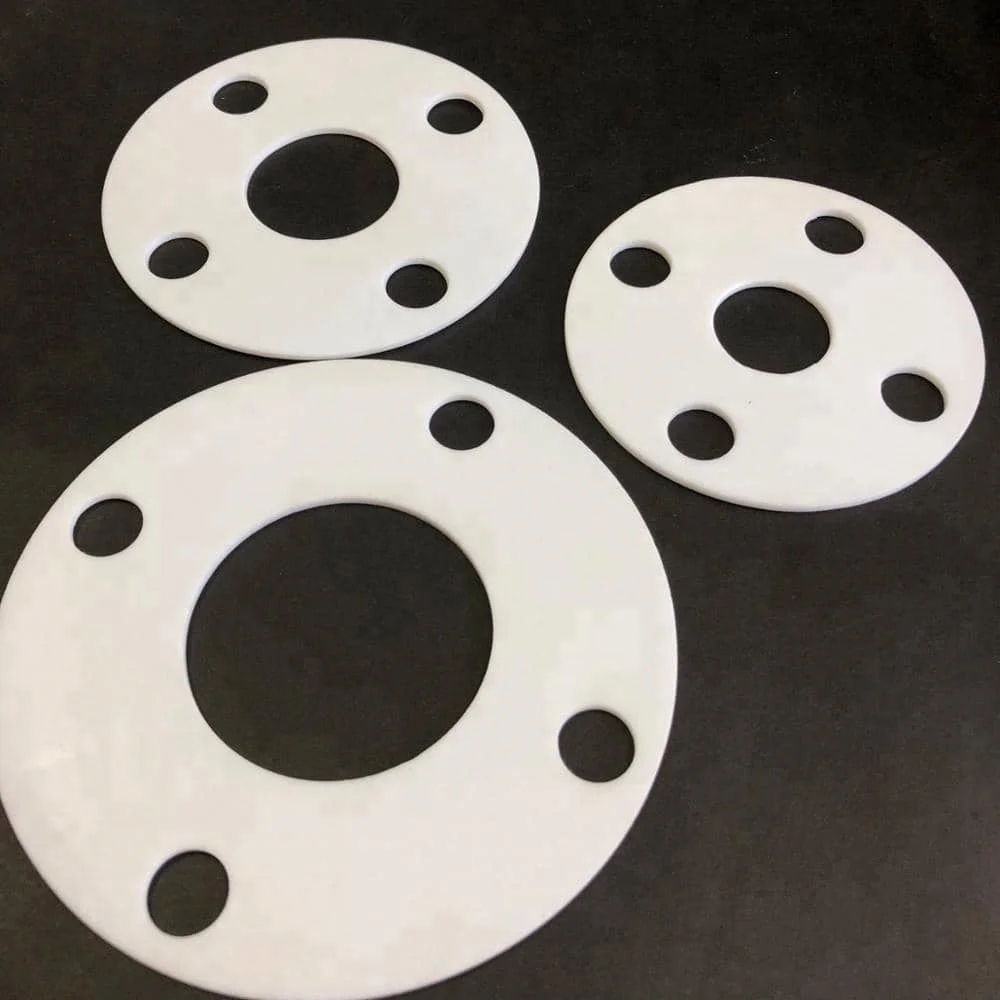

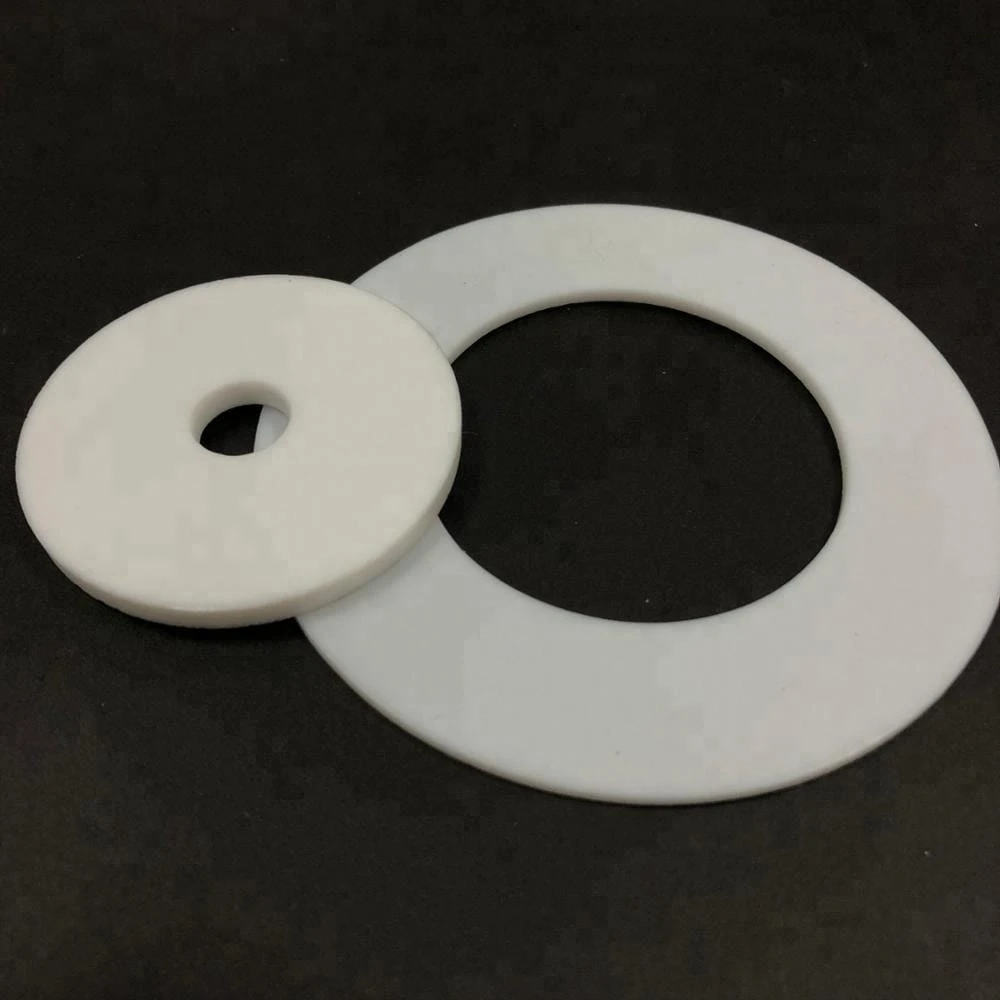

Effective sealing hinges on how well a gasket can conform to flange surface irregularities and maintain uniform compression under varying pressures. PTFE gaskets are known for their low coefficient of friction, which allows them to fill microvoids and create tight seals. However, pure PTFE can exhibit creep relaxation, meaning the material may gradually flow under continuous stress, potentially reducing bolt load and seal tightness over time. To counteract this, filled or modified PTFE (glass, carbon, or mineral filled) gaskets are often used to enhance dimensional stability and minimize cold flow.

Silicone gaskets maintain impressive elasticity and exhibit high compression set resistance, ensuring consistent gasket thickness even after prolonged service. Their soft, rubbery nature allows them to adapt to surface imperfections and maintain torque retention. In dynamic or vibrating systems, silicone’s ability to “bounce back” helps preserve seal integrity, making it less prone to leak paths forming at flange interfaces. In choosing between a ptfe vs silicone gasket for leak prevention, consider the balance between PTFE’s chemical sealing prowess and silicone’s mechanical resilience under cyclic loading.

Application Suitability in Different Industries

In the chemical processing and pharmaceutical sectors, PTFE gaskets dominate due to their unmatched purity and resistance to cross-contamination. They are often used in reactors, piping systems, and sanitary fittings where sterile conditions and aggressive fluids coexist. In food and beverage manufacturing, FDA-compliant PTFE ensures product integrity and long service life under CIP (Clean-In-Place) procedures. Conversely, silicone gaskets find favor in consumer appliances, HVAC, and automotive assemblies where rapid temperature changes and mechanical movement are routine, and ultra-high chemical resistance is not critical.

The oil and gas industry often deploys PTFE seals in subsea and high-pressure environments, leveraging their low permeability and robustness against hydrocarbons. Aerospace applications also benefit from PTFE’s light weight and thermal stability in fuel systems and instrumentation. Meanwhile, silicone’s tear resistance and flexibility make it suitable for wearable medical devices, electrical insulation, and general-purpose sealing where comfort, pliability, and moderate temperature performance are paramount. Each industry’s unique demands underscore why analyzing ptfe vs silicone gasket attributes is essential before specification.

Conclusion: Making the Informed Choice

Ultimately, selecting between a PTFE vs silicone gasket hinges on your operational priorities—be it chemical inertness, temperature extremes, mechanical flexibility, or industry-specific compliance. PTFE shines in highly corrosive, high-temperature, or sterile environments, while silicone excels in dynamic, moderate-temperature applications demanding elasticity and resilience.

By carefully assessing the chemical media, temperature fluctuations, mechanical stresses, and regulatory requirements of your system, you can pinpoint the gasket material that offers the best long-term performance, reliability, and safety for your sealing solution.